This is your ultimate guide to warehouse safety.

In this article, you’ll:

-

Learn the top safety guidelines for warehouses

-

See the latest warehouse safety statistics

-

Review OSHA’s rules and regulations on warehouse safety

-

Get 15 tips for improving warehouse safety

Let’s dive in!

What Is Warehousing Safety?

Warehouse safety includes the regulatory guidelines, actions, and best practices that help reduce injuries, provide workers with a safe environment, and reinforce safe behavior.

Specific aspects of warehouse safety include:

-

Material handling equipment operation and maintenance

-

Ergonomic handling and movement of goods

-

Use of personal protective equipment (PPE)

-

Fire and chemical safety

Why Is Safety So Important in a Warehouse?

With many on-site activities, warehouses can be dangerous places to work compared to other, less dynamic industries.

We’ll talk more about specific risks later in the article, but briefly, warehouse workers commonly face hazards associated with:

-

Forklifts and other material handling equipment

-

High heat or excessive cold

-

Heavy objects

-

Sharp objects

While each hazard presents a direct danger to the workers, the damage can also extend to their co-workers, families, and friends.

Thus, focusing on warehouse safety helps reduce and prevent these risks as well as the accompanying fallout that goes with them.

How to Measure Warehouse Safety

Improving anything first requires taking careful measurements of what you’re trying to improve.

Otherwise, how will you know if things got better, worse, or stayed the same?

To measure the overall safety of your warehouse, consider tracking the following areas.

Incidents and Injuries

Incidents, accidents, and injuries are the most obvious metrics for tracking the effectiveness of your warehouse safety programs.

The downside is that it’s a “lagging indicator,” which means the changes you make won’t be reflected immediately in the data.

Instead, the industry is shifting toward “leading indicators,” which provide shorter feedback loops to help track changes more quickly.

Near Misses

According to OSHA, a near miss is a situation where no personal injury or property damage occurred but could have with a slight shift in position or time.

Near misses provide insight into the factors that led to the unsafe incident and provide a framework for how to fix them.

Thus, regularly tracking the number of near misses can help you understand whether your warehouse is becoming safer or regressing.

Lost Time

Lost time means lost profits and each warehouse incident and/or injury will result in the loss of time in some way.

For example, an injured employee may have to miss work, spills and debris need to be cleaned up, and damaged equipment needs to be repaired.

Each of these scenarios can be converted into warehouse performance metrics to show how time losses translate into lower business profits.

Employee Feedback

Employee input is a great way for decision-makers to identify how safe workers feel, if they’re getting enough rest, and how sore or tired they get, for example.

And tracking the improvement of these metrics can give you insights into whether safety initiatives are generating the desired effect.

Moreover, acting on workers’ ideas and suggestions will help you build trust and provide evidence of your desire to give them a safer workplace.

The problem is that many employees find it difficult to talk directly to management about their workplace concerns.

One way to alleviate this problem is by bypassing upper management altogether and instead forming safety committees.

Company safety committees can serve as a neutral platform where employees can feel empowered to express themselves freely without the fear of retribution.

And besides gathering worker input, these committees can also put on events, provide training, and conduct inspections – all to help improve warehouse safety.

Lifting Intensity

Lifting items that are too heavy and doing so too often can cause excessive fatigue and risk injury for workers.

Thus, tracking lifting intensity is an important part of ensuring safe warehouse working practices.

Ideally, lifting intensity should be measured by heart rate.

But in a warehouse, tracking employees’ heart rates may not be feasible.

So the next best solution is to set lifting intensity as a percentage of a worker’s weight lifting limit.

Then, limit the maximum number of times a worker can surpass that threshold.

For instance, if the weight lifting limit is 80 lbs., set an 80% threshold (80% of 80 lbs. = 64 lbs.) and track how often workers are lifting more than that.

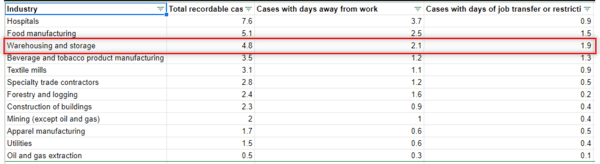

How Safe Are Warehouses?

In the United States, the warehousing industry has a higher rate of fatal injuries than other industries.

That said, the statistics in recent years have shown fewer fatal and non-fatal injuries – almost certainly due to COVID-19 shutdowns.

For instance, the U.S. Bureau of Labor Statistics reports there were 21 reported fatal warehouse injuries in the U.S. in 2020.

Compared to 2019’s 24 fatalities, that was a 12.5% decrease.

Furthermore, there were 2.7 million reported warehouse injuries and illnesses in 2020, down from 5.7% in 2019.

Why Are Some Warehouses Less Safe Than Others?

There are many reasons why some warehouses are less safe than others, including:

-

Management or employees taking shortcuts to save time

-

Reduced spending on warehouse safety training programs

-

Providing improper, incorrect, or incomplete safety training

-

Assigning fewer safety officers who can spearhead safety initiatives

-

Poor housekeeping and lack of mandated safety equipment

-

Talent and labor shortages can mean fewer experienced workers

What Are the Hazards in a Warehouse?

The 4 most common warehouse safety hazards (according to OSHA citations) are:

-

Forklifts and other powered industrial trucks (PIT)

-

Hazard communication (this covers chemical-handling safety)

-

Electrical wiring methods

-

Electrical system design

But there are many other warehouse hazards, including:

-

Lifting, lowering, pushing, or pulling items (common causes of musculoskeletal disorders)

-

Slips, trips, and falls (falls are a leading cause of death for people in general and present a danger in the warehouse)

-

Collisions and crush-hazards from working close to automated or robotic systems

-

Improper or incomplete use of personal protective equipment (PPE) like fall arrest systems

-

Obstructed or unmarked emergency exits

-

Not following proper lockout/tagout (LOTO) procedures

-

Inadequate fire safety provisions, like not having portable fire extinguishers

-

Handling hazardous materials, which can result in chemical burns

-

Improper product stacking and storage, leading to structural collapse and items falling

-

Heat and cold-related illnesses (such as when working in cold storage warehouses)

What Is the Occupational Safety and Health Administration’s (OSHA) Role in Warehouse Safety?

Many people wonder: What is the government agency responsible for monitoring worker safety in warehouse operations?

The answer is the Occupational Safety and Health Administration (OSHA).

Now a follow-up question: What are the warehouse safety regulatory standards according to OSHA?

OSHA doesn’t have specific warehouse rules and regulations.

Instead, their rules for warehouses are covered by the broader standards for general industry contained in 29 CFR 1910.

Additionally, warehouses must abide by OSHA Section 5(a)(1), often referred to as the General Duty Clause.

This clause requires employers to provide employees with workplaces that are free from recognized hazards likely to cause serious physical injuries or fatalities.

OSHA notes that:

“If a serious hazard is recognized in a workplace and the employer doesn’t take steps to abate or prevent it, they can be cited for violating the General Duty Clause.” — OSHA

So, warehouse operators need to follow OSHA’s rules for general industry as well as the General Duty Clause.

But that’s not quite all OSHA says on the subject of warehouse safety.

Despite not having rules specific to warehousing, they do note several standards that outline warehouse safety best practices, including:

-

1910 Subpart D: Walking-Working Surfaces

Concerns ladders, stairways, dock boards, and fall protection

-

1910 Subpart E: Exit Routes and Emergency Planning

Includes maintenance, safeguards, route planning, emergency action plans, and fire prevention

-

1910 Subpart F: Powered Platforms, Manlifts, and Vehicle-Mounted Work Platforms

-

1910 Subpart G: Occupational Health and Environmental Control

Concerns ventilation and noise exposure

-

1910 Subpart H: Hazardous Materials

Covers the managing, handling, and disposing of hazardous substances like LPG and anhydrous ammonia

-

1910 Subpart I: Personal Protective Equipment

Includes eye, face, head, foot, hand, respiratory, and fall protection

-

1910 Subpart J: General Environmental Controls

Covers lockout/tagout procedures among other controls

-

1910 Subpart K: Medical and First Aid

-

1910 Subpart L: Fire Protection

E.g. fire extinguishers

-

1910 Subpart N: Materials Handling and Storage

Includes forklifts, cranes, slings, and other powered industrial trucks (PIT)

-

1910 Subpart O: Machinery and Machine Guarding

Includes requirements for safety guards around machines with moving parts, such as saws, power tools, and pulley systems

-

1910 Subpart P: Hand and Portable Powered Tools and Other Hand-Held Equipment

Covers hand and portable power tools and equipment

-

1910 Subpart S: Electrical

Includes wiring methods, components, and equipment

-

1910 Subpart Z: Toxic and Hazardous Substances

Concerns proper hazard communication

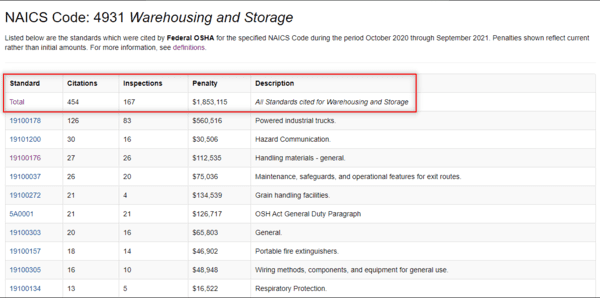

What Are the Top OSHA Warehouse Violations?

When warehouse operators run afoul of OSHA’s general duty clause or other standards, they risk hefty fines as a consequence.

For example, OSHA issued 454 citations worth over $1.8 million to warehouses and storage facilities between October 2020 and September 2021.

And the majority of these citations were for the following warehouse violations:

-

Misuse of forklifts

-

Noncompliance with OSHA’s Hazard Communication Standard for chemical safety

-

Improper wiring methods and electrical system designs [29 CFR 1910.305]

-

Failure to guard openings in walls and floors

-

Improper access to and labeling of exits [29 CFR 1910.37]

-

Noncompliance with the covering of mechanical power transmission apparatuses

-

Improper respiratory protection for workers

-

Inadequate or improper placement, inspection, and condition of fire extinguishers

-

Poor warehouse sanitation

15 Warehouse Safety Tips

What are some safety rules for a warehouse?

Let’s go through 15 key ones.

1. Fix Obvious Hazards

Every warehouse should regularly work to identify and correct all potential hazards before they become a peril.

For example, warehouse operators need to ensure floors are in good shape before workers and equipment work on them.

That means doing things like removing wet or slick substances, fixing any holes and divots, removing clutter, and keeping aisles clear.

2. Reinforce the Importance of Safety

It’s easy to forget about safety when its importance isn’t consistently reinforced.

But forgetting about safety breeds complacency, which can result in injuries – or worse.

So, how do you provide consistent safety messaging in the warehouse?

Simply by always talking about it – whether that’s in company meetings, in employee newsletters, or any other place employees come together.

For instance, you may discuss warehouse safety meeting topics like:

-

Recent incidents or accidents at the facility, including how they happened and how to avoid recurrences

-

Safety issues that workers have recently seen and how to rectify them

-

Analysis of safety issues in the news, including how to avoid the same circumstances in the workplace

3. Manage Worker Stress & Fatigue

Here are some practical methods for managing worker stress and fatigue to help prevent burnout:

-

Provide workers with scheduled time off for rest and ensure they take it

-

Encourage worker input on the issues contributing to their stress and fatigue, such as workload, pace, hours, understaffing issues, and worker absences

-

Make adjustments to the warehouse work environment, such as lighting, temperature, and physical surroundings, to increase workers’ alertness

4. Pay Attention to Risky Behaviors

Warehouses should have a zero-tolerance policy for risky behaviors and pay close attention to any evidence that they’re happening.

For example, skid marks, bent forks, or wheels coming off the ground are all indications of dangerous forklift use.

The next should involve Identifying the equipment and operator involved, then providing corrective instruction and training to discourage that behavior in the future.

5. Mitigate Electrical Hazards

Electrical hazards in the warehouse can come from components like service panels, forklift batteries, and extension cords.

Some ways to stay safe from electrical hazards include:

-

Affix signage near electrical systems like panels, generators, and batteries to warn against unauthorized entry or use

-

Ground all power supply systems

-

Ensure sufficient clearance in front of electrical panels

-

Visually inspect all electrical equipment before use

-

Be mindful of explosive hydrogen gas buildup when charging batteries (no sparks!)

-

Dispose of extension cords with any damage or defects (and replace them with cords that have a ground wire)

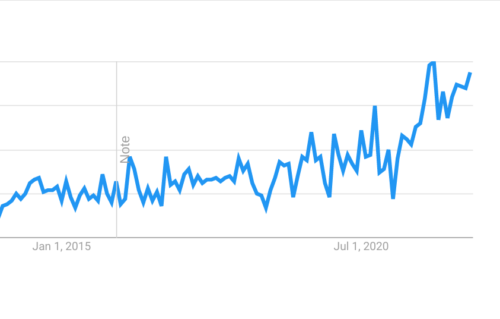

6. Use Caution and Care Around Automated Equipment

There’s no doubt that warehouse automation has become more popular over the past few years.

Automated guided vehicles (AGVs), smart conveyors, and robotic pallet wrappers are just a few automated technologies more popular today than ever before.

But with all that productivity-increasing equipment also comes the risks associated with its use near people.

That includes equipment striking workers, crushing limbs or bodies, and many other risks.

The best way to protect against this is to work around automated equipment instead of expecting the equipment to work around you.

Thus, part of automation equipment training should include making workers aware of the hazards and instructing them on how to remain vigilant when working around them.

7. Create Proper Lockout/Tagout Procedures

Equipment repair and maintenance activities in the warehouse can present ripe opportunities for injury – or worse.

Not only may the activities themselves be dangerous…

But equipment that’s not properly secured may be capable of releasing stored energy on unsuspecting workers and harming them.

To reduce this risk, warehouses must have a proper lockout/tagout (LOTO) program.

What exactly constitutes a “proper” lockout/tagout program is beyond the scope of this article.

But generally, workers should be trained on:

-

What equipment needs to be locked/tagged out and when

-

How to lock and tag equipment out

-

The procedure for returning locked equipment to service

You can read more about lockout/tagout rules and best practices on OSHA’s dedicated page.

8. Have an Emergency Plan

Every warehouse should have an emergency safety plan in place.

This should include what workers must do in case of everything from forklift accidents, fires, and chemical burns to tornadoes, hurricanes, and earthquakes.

For instance, a robust warehouse emergency plan should include:

-

Fire safety and prevention

-

Emergency exit locations

-

Evacuation routes and procedures

-

Methods for accounting for all workers and visitors

-

Fire extinguishers, eye wash stations, and first aid locations

9. Recruit Volunteer First Responders

The nature of accidents is such that they happen when you least expect them to.

Thus, it’s prudent to train and make available certain willing employees to be first responders in case of an emergency.

Some of the common injuries that first responders can attend to include:

-

Cuts and bleeding

-

Fire or chemical burns

-

Crush injuries

-

Fractures

-

Cardiac arrest

Of course, every warehouse also needs an accessible first aid kit complete with the requisite medical supplies and equipment.

So if your warehouse doesn’t have one, make getting one a top priority.

10. Provide Proper Safety Equipment

Many people wonder: “What industrial safety equipment do I need for my warehouse?”

Common warehouse safety equipment includes:

-

Hard hats

-

High-visibility vests, jackets, or overalls

-

Safety glasses or goggles

-

Safety boots with steel toe caps

But providing personal protective equipment (PPE) like the above isn’t quite enough…

Because warehouse operators must also ensure all PPE is worn when required and worn correctly.

Good times to check these things are before the start of all shifts and periodically throughout if there is cause for concern.

11. Use Extra Caution in Warm and Cold Environments

Working in warm or cold environments can prove fatal if proper precautions aren’t followed.

Both the worker and the employer need to exercise caution in these conditions, including:

-

Allowing new or returning workers to gradually increase workloads as they build a tolerance for the cold or heat

-

Allowing workers to take more frequent breaks

-

Wearing proper clothing and staying hydrated and nourished

-

Training workers on cold/heat-related illnesses, including how to spot common symptoms and what to do when they’re seen

-

Ensuring the warehouse is well-ventilated and providing equipment like cooling fans or radiant heaters

12. Have Respect for Forklifts

Forklifts are a common sight in warehouses – and also a common cause of injuries.

The following tips can help improve forklift safety in the warehouse:

-

Provide quality training for beginners and recertification training at least every 3 years

-

Enforce daily pre-trip inspections and do not use forklifts that are in a deficient operating condition

-

Keep up on scheduled and preventative maintenance

-

Install safety separators between pedestrian and forklift traffic

-

Institute and enforce forklift speed limits

-

Slow down and honk the horn at blind spots and intersections

-

Proceed with extreme caution when driving over wet or slick surfaces

-

Never turn a forklift on an incline or decline

-

Never exceed a forklift’s load capacity rating

-

Install and maintain seat belts and enforce their use among operators

-

Do not modify or make additions to the forklift that could affect its capacity and/or safe operation

13. Securely Store Materials

Storing large amounts of inventory – as is the task of the typical warehouse – can sometimes only be done by storing those goods vertically in pallet racks and shelving.

But this introduces the risk of those items falling and injuring workers.

So, how can you prevent falling objects in the warehouse?

Here are some tips:

-

Inspect and maintain your shelving and racking to prevent collapse. If damage occurs, immediately isolate the affected area

-

Install upright rack guards to prevent damage from forklift impacts

-

Ensure items, pallets, and containers are properly stacked, blocked, and, interlocked to prevent them from moving

-

Do not exceed storage shelving and rack load capacities

-

Wear head protection in case precautions fail

14. Encourage Ergonomic Lifting Practices

Lifting items is one of the top causes of injury for warehouse workers.

Ensuring that employees know how to properly lift, bend, and work in general can help reduce these injuries and all the negatives that come with them.

Here are some safe lifting best practices:

-

Replace manual lifting with engineered solutions like material lifts or forklifts as much as is feasible

-

Use the legs, keep the back in a natural position, and ask for help if a load is too heavy

-

Keep item weights under 10 lbs. (or 2 lbs. when a pinch grip is used) and tote/case weights to 35 lbs. or less

-

When consolidating orders, raise pallets or cases between the knee and mid-chest level to allow workers easier access and to reduce bending

-

Reduce lower body strain with anti-fatigue mats and comfortable, supportive shoes

-

Promote fatigue and muscle recovery by rotating job duties to allow adequate work/rest cycles

15. Prevent Slips, Trips, and Falls

The National Safety Council reports that slips, trips, and falls are the second leading cause of unintentional, injury-caused death.

While that is certainly bad news, the good news is that falls are completely preventable.

The following tips can help prevent fall injuries in the warehouse:

-

Clean up all spills immediately

-

Where floors may be wet or slippery, maintain good drainage and use grated floors, platforms, or rubber mats to provide a dry place for workers to stand

-

Inspect ladders to identify any visible defects and repair them immediately

-

Maintain 3 points of contact when climbing up or down ladders

-

Only move mobile ladders and platforms when they’re not in use

-

Make use of personal fall arrest systems for workers on ladders and mobile elevating work platforms (MEWPs)

-

Use chocks to prevent trucks, trailers, and rail cars from moving while they’re unloaded by workers or material handling equipment

Frequently Asked Questions About Warehouse Safety

Let’s go through some common questions people often ask about different warehouse safety aspects.

Are Safety Vests Required in a Warehouse?

No OSHA standard mandates wearing safety vests in a warehouse.

But, safety vests can help prevent injuries – especially where there’s moving equipment such as forklifts or pallet movers.

So although there’s no requirement, it’s still a good idea to wear safety vests in the warehouse.

What Kind of Shoes Should You Wear in a Warehouse?

If you’re working around forklifts and other material handling equipment, you should wear safety shoes with steel toes.

If you’re not working near equipment – and if your employer allows – wear lightweight shoes to help with fatigue, strain, and lower back pain while working long shifts.

For instance, some shoes recommended by warehouse pickers are Adidas Ultra Boost, DNA Athletic, Reebok Sublite, and Sketchers.

Are Cell Phones Allowed in a Warehouse?

No specific OSHA rules ban having a cell phone in a warehouse.

Instead, it’s up to the employer.

For example, Amazon recently announced that they were reversing their ban on cell phones in their warehouses.

And they are free to do this as the policy is set by the employer and not a higher government authority.

Do You Need to Wear a Hard Hat in a Warehouse?

OSHA directly addressed wearing hard hats in the warehouse back in 1976, saying, “…it is recommended that the employees be provided with such head protection.”

That said, OSHA also notes that not all workers need to wear hard hats – just those who are likely to be exposed to head injuries.

For example, a forklift operator who is protected by an overhead guard may not need a hard hat (assuming nothing small can fall through the guard and hit them, for instance).

On the other hand, workers walking in aisles may need hard hats because objects from racking could fall, risking head injuries.

In any case, it’s best to err on the side of caution and require safety equipment if there’s a foreseeable risk to employees.

Are Safety Glasses Required in a Warehouse?

There is no blanket OSHA requirement for all warehouse workers to wear safety glasses.

Instead, OSHA requires safety goggles when there’s a risk of injury from chemical, mechanical, or other environmental risks.

Thus, if there are hazards in your warehouse that would require safety glasses, they should be worn.

Need Help Improving Your Warehouse Safety?

Keeping a safe warehouse is no small job. Thankfully, we’re here to help. Contact us today to learn how.

Conclusion

That’s it: The complete guide to warehouse safety.