This article is all about comparing sit-down forklifts and stand-up forklifts.

In it, you’ll learn:

- What each type of forklift is

- The major differences between them

- What applications each is best suited for

- The training requirements for operators of both

- And lots more!

By the end of the article, you’ll be able to decide which one is best for you.

Let’s dive in!

Sit-Down Counterbalanced Forklifts: What Are They?

Sit-down forklifts are those where the operator is seated and facing forward when driving the truck.

Wondering what is a sit-down forklift called?

Answer: Sometimes they’re called counterbalanced forklifts.

Not sure what that means?

The term “counterbalance forklift” comes from the design.

As opposed to other types of lift trucks, counterbalance forklifts feature a large weight placed at the lift truck’s rear to balance the load it carries at the front.

And most sit-down forklifts are designed this way.

Characteristics of Sit-Down Forklifts

Let’s do a quick run-down of the main features of sit-down forklifts:

-

They belong to several different forklift classes, including Class I, II, IV, and V

-

Some are 4-wheel models with smaller electrics being 3-wheel

-

They are counterbalanced. As described above, this means they use a metal counterweight (and battery, if electric) to offset the load on the forks

-

They can be powered by internal combustion (gasoline, LPG, diesel, CNG) or battery

-

Some can be used only indoors, while others are designed for indoor and outdoor use

-

Lifting capacities range from 3,000 lbs. to 150,000 lbs. or more

Types of Sit-Down Forklifts

There are dozens of different types of sit-down forklifts.

Let’s cover some of the most common ones.

Sit-Down Propane Forklifts

These forklifts are the most common type you see around.

Among them, the 5,000 lbs. cushion sit-down forklift is the standard “warehouse” forklift.

But sit-down propane forklifts can come in a wide variety of capacities, from 3,000 lbs. to 100,000 lbs. capacity or more.

Sit-Down Electric Forklifts

Small-capacity sit-down electric forklifts usually come in a 3-wheel design.

But once you surpass 4,000 lbs. capacity, these trucks come in 4-wheel designs.

Other specialty models exist too, including those without a counterbalance.

One such example is the swing mast forklift:

With this model, the operator’s compartment actually moves up and down.

Additionally, the mast can pivot to retrieve stock from pallet racking.

Because of this, the truck’s chassis doesn’t have to turn, making them ideal for narrow aisle applications.

Stand-Up Counterbalanced Forklifts: What Are They?

Lots of people wonder “what is a stand-up forklift?”

As you may have guessed, stand-up forklifts are those that are operated from a standing position.

Now, what is the stand-up forklift called?

Answer: A stand-up forklift is also called a stand-on forklift.

Characteristics of Stand-Up Forklifts

Let’s do a quick run-down of the main features of stand-up forklifts:

-

They belong to both forklift classes I and II

-

They typically have 3 wheels: Two for driving and one for steering

-

They are designed to have a shorter wheelbase than sit-down riders

-

They use a battery instead of a counterweight to offset the load on the forks

-

They are only available as battery-powered – not internal combustion

-

They are designed and used almost exclusively indoors

-

Their lifting capacities usually range from 2,000 lbs. to 5,500 lbs.

Types of Stand-Up Forklifts

While there are many types of sit-down forklifts, there are comparatively fewer stand-up lift trucks.

Chief among them are reach trucks and stand-up counterbalance trucks.

Reach Truck vs. Stand-Up Forklift

First of all, what’s a reach truck?

A reach truck is a type of stand-up forklift.

However, in addition to having a conventional mast, reach trucks also have a scissor mechanism called a pantograph.

What does this mechanism do?

It allows the operator to extend and retract the forks.

And why is this useful?

Because it allows the truck to reach into racking to retrieve loads.

On the other hand, stand-up counterbalance forklifts are much like electric sit-down forklifts.

The biggest difference is simply how the operator is positioned within the operator compartment.

The Differences Between Sit-Down Forklifts and Stand-Up Forklifts

You now have a basic idea of the differences between sit-down and stand-up forklifts.

But beyond the few points listed above, there are much deeper differences to be aware of.

So let’s dig into those differences in more detail.

Safety

Advantage: Sit-Down Forklifts

Forklift accidents are one of the leading causes of injury and death in the workplace.

And so the safety of man and machine should be the top consideration when selecting a forklift.

So, which is safer: Sit-down forklifts or stand-up forklifts?

Generally, sit-down forklifts are safer.

Why?

For two main reasons:

- The use of seat belts

- There’s no need to dismount in case of a tip-over

Let’s go through the reasoning behind each.

The Use of Seat Belts

In a sit-down forklift, the operator is secured and protected inside the confines of the operator compartment and underneath the overhead guard.

Why?

Because of the seat belt.

All newly-manufactured sit-down forklifts must have seat belts.

And wearing a seat belt is a major safety requirement.

This is because, in the event of a collision or tip-over, the seat belt keeps the operator in place within the operator compartment.

And that minimizes the chances that the truck itself will land on top of the operator.

On the other hand, stand-up forklifts do not have seat belts.

Instead, the operator is loose within the operating compartment.

And in the event of a collision, the operator can be thrown around, which can result in injury.

No Need to Dismount

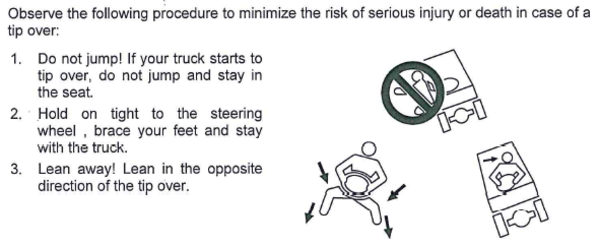

In the event of the tip-over, the operator of a sit-down forklift has another advantage.

Namely, it’s that the operator doesn’t need to consciously dismount the lift truck.

In fact, sit-down operators are advised to stay in the seat and brace themselves if the truck begins to tip.

But it’s not the same for stand-up forklift operators.

In the event of tip-over, the stand-up operator must step off the back of the forklift while it tips.

And this means that stand-up forklift safety requires the operator to have the reaction time and presence of mind to evacuate the truck.

Otherwise, they risk tipping with the machine, which can cause injury or even death.

Operating Environment

Advantage: Sit-Down Forklifts

Some sit-down forklifts – like 3-wheel electrics – are designed mostly for use indoors.

Others, like internal combustion pneumatic tire forklifts, can operate both indoors and outdoors.

Because of this, sit-down lift trucks provide greater flexibility for operating in different environments.

On the other hand, most stand-up forklifts are not designed for outdoor use.

Instead – because of their cushion and poly tires and wheels – they’re designed only for flat, indoor surfaces.

So, if your operation requires using lift trucks on a wide variety of surfaces, you’ll be better off using a sit-down forklift.

Lifting Capacity

Advantage: Sit-Down Forklifts

Sit-down forklifts have the greatest range of lifting capacities.

Electric models can lift as little as 2,500 lbs. and as much as 80,000 lbs.

Internal combustion models, on the other hand, max out around 150,000 lbs. of lifting prowess.

But stand-up models rarely go above 5,000 lbs. capacity.

This means if you need a heavy-lifting fork truck, a sit-down forklift is your best bet.

Ergonomics

Advantage: Tie

An important principle involved in selecting forklifts is how well your operators like them.

Because after all, if your operators are unhappy with their lift trucks, this can translate to safety risks, drops in productivity, and poor morale.

So, are sit-down or stand-up forklifts more comfortable for operators?

Answer: It depends on what activities they do the most.

Let’s unpack that.

When It’s Better to Sit

Let’s take the most obvious difference between the two: The operating position of the operator.

In a sit-down forklift, of course, the operator sits down.

And this is a major advantage if the operator is:

-

Traveling long distances throughout their shift

-

Working long shifts

-

Not required to frequently get on and off the lift truck

Because they’re able to sit, they’ll be more comfortable than in stand-up forklifts which don’t have a seat.

And standing in a stand-up lift truck throughout a shift can cause strain to the lower extremities.

This includes areas like the hips, legs, knees, and ankles.

When It’s Better to Stand

Now, when it comes to operations that require frequent mounting and dismounting of lift trucks, stand-up forklifts are more advantageous.

For example, if an operator’s job duties involve manually picking orders.

Because they can simply step on and off the truck without buckling and unbuckling their seat belt, they’ll experience less strain.

And this brings up another aspect of operator ergonomics for each type of forklift.

Namely, how much the operator has to travel in the forward and reverse directions.

Why does this matter?

Because sit-down forklift operators who travel in reverse often have to move more of their body to look in the direction of travel.

This is because they sit facing forward on the lift truck.

And so traveling in reverse requires them to twist their back, shoulders, and neck to see.

Repeatedly performing these motions throughout their shift can result in strain and fatigue.

And that can have consequences on both their overall health and their productivity.

Now, stand-up forklifts are better suited for these situations.

Why exactly?

Because stand-up forklift operators stand perpendicular to the direction of travel.

As a result, the operator only has to turn their head to the right when traveling forward, and to the left when traveling backward.

And this saves significantly on fatigue and strain when operating throughout a shift.

Controls and Operation

Advantage: Sit-Down Forklifts

Sit-down and stand-up forklifts vary quite a bit in how they’re controlled.

Let’s cover those differences.

Sit-Down Forklift Controls

Sit-down forklift controls, on the one hand, include a steering wheel, accelerator, and brake pedal.

In this way, operating them is much like road cars.

Of course, they also have hydraulic functions which cars don’t.

And these functions are controlled using hand levers (and sometimes finger-controlled levers).

How to Operate a Sit-Down Forklift

Like we’ve said, operating a sit-down forklift is much like driving a car.

Except for operating the hydraulic controls, which cars don’t have.

So, how does it work?

The operator sits on the seat of the forklift and turns on the ignition.

They use the steering wheel to control the direction of the lift truck.

And they use the accelerator and brake to travel.

When ready to pick up a load, the operator manipulates the various hydraulic levers to do so.

Stand-Up Forklift Controls

Conversely, stand-up forklift controls are quite different from sit-down controls.

They do have a steering wheel to control the direction of travel.

But the lift generally doesn’t have a foot pedal for accelerating or braking.

Instead, the operator uses a joystick for these functions.

That same joystick also has hydraulic functions like mast lift, tilt, and auxiliary functions like side shift.

Because of these unique controls, operating a stand-up forklift is more like playing a video game and less like driving a road car.

So, what’s the moral of the story?

Sit-down forklifts are a little more intuitive to operate compared to stand-up forklifts.

How to Operate a Stand-Up Forklift

The major difference when driving a stand-up forklift compared to a sit-down model is that operators stand perpendicular to the forklift mast instead of facing it straight on.

This allows the operator to more easily view the travel direction, whether that’s forward or reverse.

To move, the operator presses the joystick either forward or backward.

They then use the steering wheel to control the lift’s direction.

And once they’re ready to lift a load, they manipulate the hydraulic functions on the joystick to do so.

Training

Advantage: Sit-Down Forklifts

We’ve just explained that sit-down forklift controls are much different from those of stand-up forklifts.

And this has major implications for forklift training.

Sit-Down Forklift Training

Generally, sit-down forklifts are easier to learn how to operate.

Furthermore, forklift operators tend to be more familiar with sit-down forklifts than stand-up forklifts.

And that’s mostly because sit-down forklifts are more commonly used than stand-ups.

Thus, there’s not as much of a burden when it comes to sit-down forklift training.

Of course, operators still need to obtain sit-down forklift certification to prove their skills and comply with OSHA certification requirements.

Stand-Up Forklift Training

Because stand-ups are less common and use unique controls, there’s a greater burden for stand-up forklift training if operators aren’t used to them.

This brings up a commonly-asked question: Do stand-up forklift operators need a different certification than sit-down forklift operators?

And the answer is “Yes,” operators will need separate stand-up forklift certification.

This is because OSHA requires that operators receive training if operating a lift truck different from what they’re used to.

So, if you’re considering switching to stand-up forklifts, you’ll need to commit more time and money to training.

Maneuverability

Advantage: Stand-Up Forklifts

A forklift is only as good as how it can operate within any given space.

And nowadays, warehousing space is at a premium.

As a result, warehouse managers are under pressure to squeeze more products and materials into limited space.

Thus, forklift maneuverability is essential.

But when it comes to maneuverability, how do sit-down and stand-up forklifts compare?

Turning Radius

One consideration is the wheelbase.

Generally, sit-down forklifts have a longer wheelbase.

As a result, they also have a larger forklift turning radius.

Stand-up forklifts, on the other hand, have a tighter wheelbase.

And consequently, they have a shorter turning radius.

So when it comes to turning within tight aisles, stand-up forklifts have the advantage.

Right Angle Stack

When it comes to maneuverability, another aspect to consider is right angle stack, which is complementary to turning radius.

Not sure what right angle stack means?

It’s the smallest amount of space a forklift machine needs to turn and enter a pallet.

And since this is one of the most common activities that a forklift operator does, it’s a useful way of determining forklift maneuverability.

Now, let’s look at the right angle stack of a 3,000 lb. capacity 3-wheel electric sit-down forklift.

Why this model?

Because of all the types of sit-down forklifts, 3-wheel electrics are closest in maneuverability to stand-up forklifts.

So, what is the right angle stack of a Toyota 3,000 lbs. capacity 3-wheel forklift?

Answer: 72.1 inches

Now, let’s compare that to a Toyota 3,000 lbs. capacity stand-up rider forklift carrying the same load:

Answer: 68.8 inches

As you can see, the stand-up forklift has a 3-inch advantage in maneuverability over the same capacity sit-down forklift.

And while 3-inches may not seem like much, in shrinking warehouse aisles, every inch matters.

The moral of the story?

Stand-up forklifts are a better option for operations that require greater maneuverability in tight spaces, like narrow aisles.

Overhead Clearance

Another consideration is the vertical height of the lift itself.

Sit-down forklifts in general are designed with a shorter vertical height.

And because of this lower profile, they’re better suited for operations where overhead clearance is an issue.

For example, let’s say you have standard doorways in your facility that your lift trucks must go through.

A 3-wheel sit-down electric forklift (with a lowered overhead guard and mast) would be able to make it through a standard doorway.

But a stand-up forklift would typically not be able to.

So, if overhead clearances are a concern, you may be best off looking into sit-down forklifts.

Cost

Advantage: Sit-Down Forklifts

Which costs more: Sit-down forklifts or stand-up forklifts?

Answer: Assuming similar specifications, stand-up forklifts cost more.

Let’s dig into some actual numbers to see how much more.

How Much Do Sit-Down and Stand-Up Forklifts Cost?

Overall, forklift prices vary depending on capacity, fuel type, and condition, among other factors.

So, to ensure we’re comparing apples-to-apples, we’ll make a few assumptions about the sit-down and stand-up forklifts we’re comparing:

- Capacity: 3,000 lbs.

- Fuel Type: Electric

- Condition: New

Based on these factors above, how much does a sit-down forklift cost?

Answer: Between $21,500 and $25,500.

Now, what is the average stand-up forklift price?

Answer: Between $26,000 and $34,000.

We should also mention that the above prices do not include the cost of the battery and the charger.

These can add another $10,000 or so to the cost of the truck.

So as you can see, stand-up forklifts generally cost more than sit-down forklifts.

How to Choose Between a Sit-Down and Stand-Up Forklift

Now that we’ve covered the major differences and pros and cons of sit-down and stand-up forklifts above, you should have a clearer idea of which is right for you.

But to make it even easier, we wanted to condense what we’ve covered above into a series of questions.

Key Considerations for Forklift Selection

Consider each question in the context of your operation to find out which type of fork truck is right for you:

-

How long do your operators spend traveling?

If longer travel times are required, sit-down forklifts are a better option

-

How often do your operators leave the truck?

A stand-up model is a good choice if the operator needs to mount and dismount the lift often. If the operator doesn’t need to leave the machine frequently, a sit-down forklift can help minimize discomfort

-

How often do your operators change travel direction?

A stand-up forklift is ideal if the operation will require driving in reverse more than 25% of the time

-

How much space do you have to maneuver in?

Does your workplace have narrow aisles or wide-open spaces? Are there short doorways to navigate? Stand-up forklifts are best for narrow aisles, while sit-down forklifts can maneuver through lower height spaces effectively.

-

Where do you most often use your lift trucks?

Sit-down forklifts can work indoors and outdoors. But stand-up forklifts are mostly for indoor operations

-

What products and materials are you handling?

Sit-down forklifts can handle larger loads and heavier weights than stand-up models

-

Do your operators have more experience with one forklift type over the other?

Sit-down forklifts are more common. If your operators don’t have training on stand-up forklifts – or if they simply don’t like them – you may face difficulties with training and morale if you opt to go with them

And one more thing…

Before deciding, ask your dealership to send you whichever forklift you’re interested in.

That way, you can determine if it’ll work for your operations and if your operators will like it.

And this will save you a considerable amount of time, effort, and frustration while contemplating your decision.

Conclusion

That’s it: You now have a full comparison of sit-down and stand-up forklifts.