Kolbe Windows & Doors is a leading national manufacturer of premium windows and doors tailored for residential and commercial applications.

Based in Wausau, WI, Kolbe serves the United States and Canada. What started as a two-brother operation has grown to hundreds of employees and has been operating for over 75 years.

CASE STUDY HIGHLIGHTS

CHALLENGES

Like many businesses, Kolbe has faced labor shortages over the past few years.

We knew with the way the labor market was going that we were going to have a tough time hiring workers.

Vicky Blumm, Warehousing/Extrusions Manager

In addition to labor shortages, the executive team believed that too many of their team members were involved in physically moving materials instead of focusing on more productive tasks like producing finished products.

It was clear to Kolbe that this issue needed to be solved.

SOLUTIONS

AGVs: A Familiar Technology

When searching for a solution, the first thing that came to mind was Automated Guided Vehicles (AGVs), a technology Kolbe was familiar with.

After working with the technology for 15 years and conducting trials and tests to assess their effectiveness, Kolbe believed AGVs could address their labor issue. As a result, Kolbe reached out to Conger Industries for a Toyota automated tow tractor demonstration and an implementation plan.

After witnessing the demo and reviewing the proposed plan, the Kolbe team was impressed, fully supportive, and eager to proceed.

The Ramp Issue

Before making a final decision, a significant hurdle needed to be addressed.

A multi-level ramp within their facility had proven to be tricky to navigate, and the Kolbe team wanted to ensure that the AGVs could safely and efficiently maneuver it.

Some of the other vendors that we talked to just said, No way, we can’t do ramps.

Brad Heil, Manufacturing Engineer

Fortunately for Kolbe, the Conger team was prepared to tackle the ramp challenge despite the reluctance of other companies.

After performing a series of tests, the Conger team determined the proper equipment parameters based on the ramp grades and load capacity. Once this information was in hand, they were able to certify that the AGVs could handle the ramps and they could proceed with the implementation process.

IMPLEMENTATION

Digital Mapping

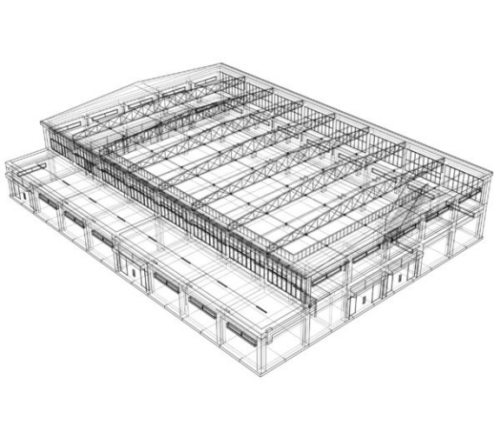

With the ramp issue resolved, the implementation process could begin. The initial step was for Kolbe to create digital maps of their facility.

The digital maps were essential to allow the vision systems on the AGVs to map out their route. Once the mapping was complete, the next step for the Conger team was to identify the most efficient routes for the AGVs.

Test Runs to Identify Issues

To plan the routes of the AGVs, the teams trialed the intended AGV path using the existing operated tugger vehicles at Kolbe, set to the same speed and route.

By mimicking the AGV settings on our existing equipment, we were able to identify any problems beforehand and address them before the AGVs showed up.

Brad Heil, Manufacturing Engineer

This experiment turned out to be a critical step in the implementation process.

We changed the whole programming that we originally had planned on going with once we put this test in place.

Vicky Blumm, Warehousing/Extrusions Manager

Fast Implementation

After completing the trial runs, the Conger team, accompanied by a team from Bastian Solutions, arrived and began working. By the third day of implementation, the AGVs were operational.

Given that Kolbe had scheduled a two-week implementation, they were delighted with the swift turnaround.

I was quite pleased with how quickly it went.

Brad Heil, Manufacturing Engineer

Following the installation of the AGVs, the Kolbe crew had the opportunity to observe the vehicles running their routes and discuss any questions or concerns with the installation crew.

A Slight “Hiccup” Easily Solved

Despite the test runs aimed at identifying and resolving any issues with the actual operation of the AGVs, a problem emerged during implementation.

After digitally mapping the facility, the Kolbe team relocated a piece of equipment. Consequently, some AGVs lost connection with the Wi-Fi system and stopped functioning.

Fortunately, Conger/Bastian promptly provided detailed instructions on how the Kolbe crew could resolve the issue.

RESULTS

Labor Savings and Fast ROI

Kolbe has been very impressed with the results of its Toyota automated tow tractors.

Today, we’re looking at about a 20% reduction in labor for material handling, which puts our return on investment at under 12 months.

Vicky Blumm, Warehousing/Extrusions Manager

This result surpasses their initial expectation of an 18-month return on investment by 33%.

With their labor force freed up, Kolbe redeployed its workforce to the final assembly areas for manufacturing. As a result, the company produces more high-quality windows and doors by focusing on production rather than material handling.

Easy to Use

From an operational standpoint, AGVs are straightforward. Each tow tractor operates based on “missions,” which are relatively easy-to-program instructions for the vehicle.

Today, we’re looking at about a 20% reduction in labor for material handling, which puts our return on investment at under 12 months.

Vicky Blumm, Warehousing/Extrusions Manager

Once programmed, the tow tractors run in a loop, stopping at designated points, and are loaded and unloaded by human workers.

Some Unexpected Benefits

This project improved teamwork and cohesion among those responsible for the AGVs as they must collaborate closely to maintain a smooth production flow. Additionally, Kolbe observed a decrease in noise levels within their facility, a welcomed change for employees.

The Bottom Line

So, what was the outcome for Kolbe?

The Toyota AGVs are very effective.

Vicky Blumm, Warehousing/Extrusions Manager

Additionally, Kolbe was pleased with how Conger/Bastian remained committed despite significant planning changes along the way.

At the beginning of this project, our whole strategic planning ended up changing direction. But the Conger/Bastian team was willing to come in and work with us. They stuck with us through the whole thing.

Vicky Blumm, Warehousing/Extrusions Manager