teNeed to know OSHA’s forklift refresher training requirements?

Then you’re in the right place.

Because in the article, we’ll lay out everything you need to know about them, including:

- OSHA’s 7 key forklift refresher training requirements

- The benefits of forklift refresher training

- What topics are usually covered during forklift refresher training

- How to choose a quality forklift refresher training program

- Where to find forklift refresher training courses

Let’s dive in!

What Are OSHA’s Forklift Refresher Training Requirements?

OSHA dictates that refresher training must include “an evaluation of the effectiveness of that training” and an evaluation of the operator’s performance. Per standard 1910.178(l)(4), it must also be conducted at least every 3 years. And it must be provided if any one of the following 5 situations arise:

- The operator has been observed to operate the vehicle in an unsafe manner.

- The operator is assigned a different type of lift truck.

- The operator has been involved in an incident or near-miss.

- The operator’s evaluation reveals they aren’t using proper forklift safety procedures.

- Changes in the workplace could affect the safe operation of the forklift.

What Can “Trigger” Forklift Refresher Training?

Let’s discuss the specific scenarios that can trigger the forklift refresher training requirement.

Three Years Go By

Per the forklift refresher training OSHA standard 1910.178(l)(4)(iii), all powered industrial truck operators must be evaluated every 3 years.

That’s regardless of safety record.

In other words, even if a forklift operator has a perfect record with no accidents, near-misses, observed unsafe behavior, etc., they still must undergo refresher training every 3 years.

It should be noted that this regulation applies to all forklift operators and workers who use any forklift machine as part of their duties.

Operating in an Unsafe Manner

OSHA 1910.178(l)(4)(ii)(A) requires refresher training when the operator is not safely operating the machine.

For example, if an operator is driving a counterbalance lift truck forward with a load blocking their line of sight. Because doing so violates a key rule of safe forklift operation, the operator should undergo refresher training on effective forklift use and operation.

An Accident or Near-Miss

OSHA standard 1910.178(l)(4)(ii)(B) dictates that refresher training must happen when the operator is involved in a forklift accident or a near-miss incident.

For instance, a collision with an oncoming vehicle or pedestrian. Or a near tip-over. Technically, something as seemingly “little” as a tire coming off the ground constitutes a tip-over. This may show that the operator does not understand how to effectively operate a forklift, which requires retraining.

A Deficient Evaluation

Part of forklift operator certification requires an evaluation of the operator actually using the forklift in the workplace. If during this evaluation the evaluator observes something that indicates the operator does not understand some aspect of safe forklift operation, then the operator needs to undergo refresher training.

OSHA regulation 1910.178(l)(4)(ii)(C) states that refresher training is needed when “the operator has received an evaluation that reveals that the operator is not operating the truck safely.”

Assigned a Different Type of Fork Truck

When the operator has been assigned to drive/operate a different type of forklift truck, they need training specific to that particular truck.

For example, an operator trained and evaluated to use a sit-down counterbalanced rider will need refresher training when assigned to an operator-up counter-balanced front/side loader or a rough terrain forklift truck.

These machines have different characteristics and don’t operate the same. Conversely, the operator may not require refresher training when assigned to operate the same type of truck but from a different forklift manufacturer, unless it has sufficiently different characteristics.

Working Conditions Change

An operator needs refresher training when a condition in the workplace changes in a manner that could affect the safe operation of the truck.

For example, if the operation has been happening indoors and now the operators have to move outdoors, they may need refresher training on outdoor operations. This includes relevant topics like site inspection, machine inspection, and others.

What Can Happen If You Neglect Forklift Refresher Training

Here are some potential outcomes of neglecting forklift refresher training:

Imperiled Employees

Forklifts are powerful and complex machines that require skillful operation. Without regular refresher training, operators may forget important safety protocols and become complacent, leading to an increased risk of accidents.

Operators needed updated knowledge about safety regulations and procedures to avoid collisions, tip-overs, and other hazardous incidents. In fact, forklift accidents happen frequently. There are approximately 85 fatalities and 34,900 serious injuries every year. And many are caused by a lack of forklift safety training.

More Destruction

Besides the human costs, forklift accidents can also cause significant damage to property, infrastructure, and other equipment in the workplace. Also, inexperienced or untrained forklift operators may unknowingly misuse equipment, leading to accelerated wear and tear of forklift machines. This increases maintenance and repair costs and downtime for repairs, impacting overall productivity.

OSHA Fines

Refresher training violations remain one of the top 5 forklift-related OSHA violations. It’s considered a “serious” violation and comes with a minimum fine of $1,036 and a maximum fine of $15,625 (in 2023).

To be sure, OSHA is serious about punishing offenders.

For example, in 2018, an Ohio company received multiple citations and fines of over $69,000 after a worker died in a forklift accident. Investigation revealed that the operator had not received refresher training.

Some companies don’t realize the triggers mentioned above require immediate refresher training – even if it’s only been less than 3 years since the operator’s initial certification.

Sometimes you may perceive a near miss as “normal” at a workplace, but it’s not. It’s important to flag every unsafe incident and never allow such “gray” areas to exist in your compliance with OSHA requirements.

8 Benefits of Forklift Refresher Training

Why is forklift refresher training required?

OSHA says that the goal is “to ensure that the operator has the knowledge and skills needed to operate the powered industrial truck safely.”

But let’s dig a little deeper into some of the important benefits of forklift refresher training.

1. Enhanced Workplace Safety

The primary benefit of forklift refresher training is workspace safety improvements.

Training ensures that operators are up-to-date with the latest safety protocols, best practices, regulations, hazard identification, risk mitigation, and safe operating techniques.

This knowledge and awareness empower operators to take proactive steps to reduce the risk of accidents, injuries, and property damage.

2. Updated Forklift Operation Knowledge and Skills

Like any other skill, operating a lift truck requires practice and continuous learning.

Forklift refresher training is how operators can get up to speed on the latest industry standards and best practices for operating lift trucks.

This helps operators to keep up-to-date with any changes in:

- Forklift types.

- Forklift innovations.

- Parts of a forklift and their functions.

- OSHA regulations for forklifts.

3. Increased Productivity and Efficiency

Properly trained forklift operators are more proficient and efficient in their tasks, which improves productivity in the workplace.

Forklift refresher training helps operators refine their skills, learn new techniques, and become more comfortable with equipment updates or advancements.

This helps them to improve productivity and operational efficiency. This leads to smoother material handling processes, optimized workflows, reduced downtime, and increased output.

Additionally, operators who understand the latest techniques and innovations can perform tasks more effectively, minimize errors, and expedite operations.

4. Less Downtime

Forklift accidents and near-miss incidents can lead to equipment damage and unplanned downtime.

Refresher training equips operators with the knowledge to prevent common mistakes, such as collisions or improper handling, reducing the risk of equipment breakdowns. Avoiding accidents and minimizing equipment downtime, increases productivity and reduces downtime.

5. Prevents Operator Complacency

If refresher training wasn’t required, and all operators had to do was get their forklift license the one time, it would be easy to slide into a mindset of safety complacency.

Forklift refresher training serves as a safety reminder and call-to-action to renew focus on responsible lift truck usage.

6. Lower Insurance Premiums

Insurance companies may offer reduced worker’s compensation premiums when they prioritize safety and provide ongoing training to forklift operators.

By maintaining a comprehensive training program, organizations can demonstrate lower risk. This may make you eligible for lower insurance premiums and result in cost savings.

7. Lower Maintenance Costs

Operators who undergo forklift refresher training are less likely to damage forklift equipment. Considering that even a single component can cost thousands of dollars, this can help reduce maintenance and repair costs.

8. Higher Morale and Engagement

Investing demonstrates an organization’s commitment to employee safety and well-being. When workers feel valued and supported, it positively impacts morale and job satisfaction.

Trained operators are more likely to feel confident in their abilities, leading to higher engagement, motivation, and a positive work environment. This also helps improve productivity and work output.

What Topics Are Covered in Forklift Refresher Training?

Subjects that Reinforce Understanding

In an explanation letter, OSHA clarifies that refresher training should complement the initial training the operator received (under regulation 1910.178(l)(3)). In other words, refresher training should reinforce what the operator already knows. But it doesn’t necessarily mean completely retraining them.

Must Include Hands-On Evaluation

Also, keep in mind: Providing a written exam isn’t enough to constitute refresher training. OSHA makes clear that refresher training must include an evaluation of the operator actually operating the lift truck.

Ultimately at the Employer’s Discretion

The amount of refresher training needed ultimately depends on the employer’s discretion. When determining what forklift refresher topics to cover, employers should take into account specifics like:

- The operator’s skills.

- Operation requirements.

- The working environment.

- The specific attributes of the new truck.

- Any other relevant OSHA guidelines.

10 OSHA Forklift Refresher Training Examples

Here are examples of common subjects addressed during forklift operator refresher training:

Safety and Compliance

- Safety regulations and standards. Update operators on the latest safety regulations and standards related to forklift operation. This may include understanding relevant local laws, and industry guidelines, reading forklift data plates, and compliance requirements.

- Forklift inspection and maintenance. Review pre-operation inspection procedures to ensure the forklift is in safe working condition. How to identify and report any mechanical issues or defects promptly.

- Review of company policies and procedures. A review of protocols related to forklift operation may also be covered in a refresher training. This ensures operators are aware of any specific rules or guidelines established by the organization.

- Emergency situations and incident response. Include instruction on responding to emergencies or unusual situations, such as handling accidents, equipment malfunctions, power failures, evacuation procedures, fire safety, and first aid awareness.

Operational Skills and Awareness

- Load handling and stability. Refresh operator knowledge and skills on how to assess load weight, size, and stability to determine safe lifting procedures. Topics covered include forklift load centers, proper stacking techniques, preventing load shifting, understanding load capacity limits, and handling hazardous materials or fragile loads.

- Pedestrian safety and communication. Emphasize the importance of pedestrian safety around forklift operations. Operators learn techniques for effective communication, including horn usage, hand signals, maintaining clear lines of sight, and strategies to prevent collisions.

- Environmental factors and special conditions. Address operating forklifts in specific environments or conditions, such as working on ramps, inclines, outdoor settings, or confined spaces.

- Ergonomics and operator well-being. Cover ergonomic principles to minimize operator fatigue, discomfort, and injuries. Topics can include proper seating posture, seat adjustment, and techniques to reduce body strain during prolonged operation.

- Safe operating techniques. Topics in this area can include starting, stopping, and maneuvering the forklift, maintaining stability, positioning the forks correctly, safe forklift speed, controls, braking techniques, and turning procedures.

- Hazard awareness and risk assessment. Emphasize identifying and mitigating hazards in the workplace. Operators learn to recognize potential risks such as uneven surfaces, pedestrian traffic, narrow aisles, or overhead obstacles.

How to Choose a Quality Forklift Refresher Training Program

When evaluating training options, it’s essential to choose a reputable and recognized training provider that can meet your specific needs.

Here are some key considerations to help you choose the right training program:

Training Program Quality

- Accreditation and certification. Look for a training program that is accredited by recognized organizations or regulatory bodies. Accreditation means that the training provider meets certain standards of quality and compliance and can offer certification upon completion.

- Experienced and qualified instructors. The training program should be offered by certified, experienced, and knowledgeable instructors with expertise in forklift operations, safety regulations, and instructional techniques.

- Comprehensive curriculum. Review the training program’s curriculum to ensure it covers all essential and relevant topics of forklift refresher training. A well-rounded forklift refresher training curriculum will help reinforce critical skills and knowledge. The program should also be able to train and certify operators on all types and classes of forklifts.

- Compliance with regulations. Ensure that the training program aligns with relevant safety regulations and industry standards. Verify that the program covers the necessary legal requirements and can help maintain compliance with applicable laws and regulations. Ensure the program can educate the management on regulations and standards to ensure compliance.

- Practical training. OSHA mandates that every forklift operator receive training that includes a hands-on, practical component to demonstrate their skills. The program should include sufficient practical training sessions before evaluation.

- Customization to workplace needs. Every workplace has unique challenges, layouts, and operational processes. Consider tailoring refresher training program to your specific workplace requirements. A quality training program should be flexible to address specific needs.

External Factors and Reputation

- Reviews and recommendations. Research the reputation and reviews of the training program or provider. Look for feedback from other individuals or organizations who have undergone the training. Positive reviews and recommendations indicate a track record of quality and effectiveness.

- Curriculum language. Language is an essential consideration. Verify that the program is available in a language trainees will understand.

- Cost and value. It’s important to evaluate the training program’s cost and value proposition. Compare the fees with the quality of the program, instructor expertise, and available resources.

For questions about forklift safety, OSHA forklift training requirements, or to schedule an on-site evaluation, please contact your nearest Conger location.

Where to Find Forklift Refresher Training Courses

Here are your options for forklift refresher training courses:

Authorized Forklift Dealerships

Many material handling dealers – including Conger Industries – provide training courses, including refresher training, as part of their services. You can check with local dealers to see if they offer training programs. Try a google search for “forklift refresher training near me” and browse through the results and pick out the dealerships.

Occupational Safety Organizations

Organizations dedicated to occupational safety often offer training courses, including forklift refresher training. For example, the National Safety Council offers several safety training courses.

Community Colleges and Technical Schools

Community or technical colleges often provide industrial training programs, including forklift training or forklift refresher training. A google search of educational institutions in your area can reveal if they offer such courses.

Online Training Providers

Many online outfits have popped up in recent years offering forklift If considering this path, it’s important to ensure the course includes the topics needed to satisfy OSHA’s requirements. Also, keep in mind the hands-on evaluation. If the training is 100% online, you must ensure all operators also complete the practical portion on a real lift truck before they can be recertified.

Forklift Refresher Training Formats: Online, In-Person, and Hybrid

You can get the refresher training in 3 formats:

- Online

- In-person

- Hybrid (combination of online and in-person)

Let’s discuss each in more detail.

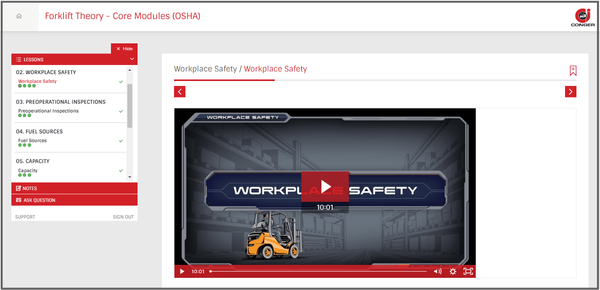

Format 1: Online Forklift Operator Training

Many online forklift certification programs have become available in the last few years. The advantages of training courses are that they’re inexpensive, widely available, and can be conveniently completed at your own pace.

The disadvantages are that they may be varying quality, and may have little support if you have questions on the material. But their biggest downside is that many do not offer the hands-on portion of training, which is required for full OSHA compliance.

Format 2: In-Person Forklift Operator Training

It’s like a classroom lecture with an instructor, PowerPoint or projector presentation, videos, and opportunities to ask questions. Group activities are also popular. And, when you complete the in-class portion, you’ll move on to the hands-on evaluations.

This type of training is excellent for the personal attention it offers. Trainees get direct access to instructors, who can tailor the teaching to individual learning styles. Moreover, this type of training typically includes the hands-on training portion with actual forklifts. The main downsides of this training are that it’s more expensive and less widely available.

Format 3: Hybrid Forklift Operator Training

A hybrid forklift operator training model is a combination of online training and in-person training. Commonly, the online training portion covers the theory. Then the in-person portion includes the hands-on forklift evaluation.

For example, Conger offers a hybrid forklift operator training and refresher program. Training includes a 2-part blended approach. Part 1 is the classroom training portion (done online). Part 2 is the hands-on evaluation (done in person, at your facility).

Hybrid forklift operator training offers the best of both virtual and in-person training. It gives the flexibility and convenience of online training with the practical training necessary to satisfy OSHA requirements.

Common OSHA Forklift Refresher Training Requirements Questions

What Is a Forklift Refresher Course?

A forklift refresher course is a training program designed for existing forklift operators who need to update their operating skills and knowledge.

It’s a retraining program that covers relevant topics for each operator, such as load lifting, safe driving practices, pedestrian safety, and so on. The goal of the refresher training is to ensure forklift operators keep safety top-of-mind to reduce incidents in the workplace.

What Is the OSHA Standard for Forklift Training?

The OSHA standard for forklift training is outlined in 29 CFR 1910.178(I). This standard defines the key criteria required for training aspects like formal classroom instruction, practical training, evaluations, and certifications.

Who Can Train, Evaluate, and Certify Forklift Operators?

According to OSHA regulation 1910.178(l)(2)(iii), forklift operators can only be trained, evaluated, and certified by individuals who possess the “knowledge, training, and experience to train powered industrial truck operators and evaluate their competence.”

In practice, it’s at the employer’s discretion to ensure they only select trainers that meet or exceed OSHA’s requirements. Employers should consider a combination of education, experience, certifications, and other relevant attributes when choosing their forklift operator trainers.

How Often Does OSHA Require Forklift Training?

There are no OSHA forklift refresher training annual requirements. Instead, OSHA standard 1910.178(l)(4)(iii) mandates that every forklift operator undergo refresher training and evaluation at least every 3 years. OSHA also notes 5 other behavioral and workplace circumstances that invoke the need for refresher training, even if it’s been less than 3 years.

How Long Do Forklift Certifications Last?

Per OSHA, forklift operator certification is valid for 3 years. After those 3 years, OSHA standards require that forklift operators be provided forklift refresher training.

The refresher training is also required under several other conditions, including if the operator is observed to be operating the forklift in an unsafe manner, has to drive a different forklift, or if workplace conditions change.

Do We Need to Provide Forklift Operator Training for Each Make and Model?

You don’t necessarily have to offer forklift operator training for each make or model of forklift you have. Forklift operator training is required when the type of forklift the operator will be assigned is sufficiently different from what they’ve been trained on. For example, a sit-down vs. stand-up lift truck. Or an order picker vs. pallet jack.

How Long Is a Forklift Refresher Training Course?

OSHA doesn’t give a set forklift refresher course “length.” Instead, they require that employers provide as much instruction as needed to ensure that operators possess the skills and knowledge needed to safely operate their forklifts.

Practically speaking, that may mean the refresher training can be done in a few minutes or a few hours – depending on how deficient the operator’s knowledge and skills are. However, a fully comprehensive forklift training course, including evaluation, can be completed in about 6 to 8 hours.

Conclusion

That’s it: The complete guide to OSHA’s forklift refresher training requirements.