Are you in the market for a forklift but have questions about the price of new or used models?

Well, you are in the right place!

This guide will help you understand new and used forklift pricing as well as:

- Why price isn’t the only thing to consider.

- The benefits and drawbacks of buying new or used.

- How to choose a forklift that suits your needs.

- The average lifespan of forklifts and factors that affect it.

- Ways to ensure your decision makes financial sense.

- Options for where to purchase your next forklift.

Let’s dive in.

In case you are just here for the pricing?

How To Determine Forklift Pricing

Asking the question, “How much does a forklift cost?” is like asking how much a car costs.

If you were to ask a car dealer about pricing, they’d probably respond with a few questions:

- What kind of car?

- How much horsepower do you want?

- What options are you looking for?

- What year do you want?

- How many miles are acceptable?

- What kind of warranty do you need?

Similarly, forklift pricing varies based on specific factors.

However, before diving into actual numbers, let’s explore the key elements that influence the price of both new and used forklifts.

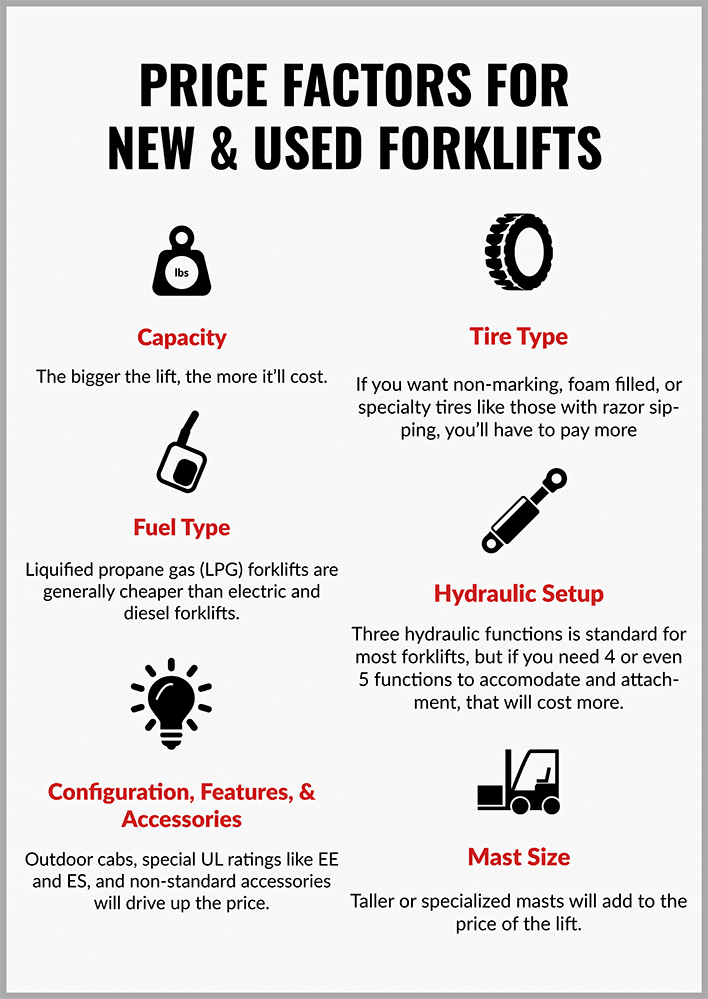

Factors That Influence Forklift Pricing

The main factors that play a role in determining a forklifts cost include:

- Lift capacity

- Fuel type

- Mast size

- Tire type

- Hydraulic system

- Configuration, features & accessories

We’ll explore each factor in more detail below.

Lift Capacity

A forklift’s lift capacity directly impacts its price, as higher capacities require more materials, making the truck more expensive.

For example, a 10,000 lb. forklift can be almost twice as expensive as a 5,000 lb. truck.

So, keep that in mind as you shop.

Fuel type

Forklifts are powered by three main fuel sources: electric, liquefied propane gas (LPG), and diesel.

Electric forklifts tend to have the highest upfront costs.

This is because their industrial batteries, which serve as both the power source and a significant part of the purchase price, effectively cover the cost of “fuel” in advance.

Diesel forklifts, while more affordable than electric models, are generally more expensive than LPG options.

Their higher price is due to the robust, heavy-duty components required to handle the demands of diesel engines.

LPG-powered trucks, conversely, are usually the least expensive option.

Additionally, the cost of the LPG fuel itself is less than the cost of diesel per unit by as much as 50%.

Mast size

In the material handling industry, an 189″ three-stage mast is considered the “standard.”

However, there is a wide variety of lift heights and configurations available to suit different needs.

Some masts are shorter, designed specifically for operating in confined spaces such as inside semi-trailers.

Others are much taller, built to access racking that reaches heights of 25 feet or more.

Generally, the taller the mast, the more material is required for its construction, which increases the overall cost.

Tire type

Depending on the forklift model, you can choose from cushion, air-filled pneumatic, or solid foam-filled tires.

Additionally, specialized options like razor-siping for slick conditions or non-marking tires for operations where floor cleanliness is a priority are available.

Black cushion and air-filled pneumatic tires are typically standard on most forklifts.

However, if you’re looking for upgraded options—such as foam-filled tires or dual-drive configurations—be prepared to spend anywhere from $1,500 to $4,000 or more.

Hydraulic system

Most forklifts come equipped with a standard 3-way hydraulic valve and single internal hosing.

This setup allows the truck to perform three key functions: lifting, tilting the mast, and controlling a side shifter for lateral movement.

For specialized attachments—such as a side-shifting fork positioner, paper roll clamp, or slip-sheet attachment—you’ll need an additional hydraulic valve section.

Adding these features will increase the overall cost of the forklift.

Configuration, Features & Accessories

The more features and specific configurations your forklift requires, the higher the price tag will be.

Common upcharges include:

- Cab: A full cab with a heater for operator comfort comes at an additional cost.

- Paint: Custom color schemes, such as your company’s branding, will add to the price.

- Specialized Options: Packages like cold storage configurations for freezer use or ES, EE, and EX ratings for hazardous environments also increase costs.

Accessories can further impact the price.

Safety and ergonomic enhancements like blue and red zone safety lights, LED headlights, and suspension seats are growing in popularity.

While these features improve workplace safety and comfort, they usually come at a premium—often costing several hundred dollars or more.

More Price Factors for Used Forklifts

When evaluating prices for used forklifts, additional factors come into play compared to new equipment. Key considerations include:

- Condition of the forklift

- Thoroughness of the seller

- Year

- Hours

- Supply & Demand

- Warranty

- Paint

- Attachment

- Negotiation

Let’s break down each factor:

Condition of the forklift

The environment in which a forklift was previously used can greatly affect its condition and price.

Forklifts that operated in extreme conditions often show signs of wear and tear, which should be reflected in their cost.

Common working conditions to be cautious of include:

- Proximity to salt water: Increases corrosion on machine components.

- Cold environments: Makes engine and hydraulic seals brittle over time.

- Humid environments: Promotes moisture intrusion and electrical system corrosion.

- Heavy outdoor use: Exposes forklifts to elements like rain, dirt, and rust.

Thoroughness of the seller

“As-Is” Sales:

Some sellers take a minimal approach—offering forklifts with only a cursory inspection or no repairs.

These trucks are often sold “as is” and can be found on platforms like eBay, Craigslist, or auction sites for as little as $3,000.

However, these “great deals” often come with risks, such as extensive rust, worn tires, or damaged components.

While affordable upfront, such forklifts often require significant repairs, which will ultimately impact your budget.

Self-Promo Alert!

At Conger, we conduct a thorough 47-point inspection on every used forklift to guarantee it functions properly before the sale.

Year

Like automobiles, newer forklifts generally command higher prices than older ones.

Older forklifts often have outdated features and more wear and tear due to prolonged usage.

The age of a forklift plays a critical role in its pricing. If possible, aim to purchase equipment that is ten years old or newer.

Forklifts older than ten years are typically priced much lower, but they may lack modern features or require more maintenance.

Hours

Forklift usage is measured in operating hours, not miles.

As a rule of thumb, 200 hours on a forklift is equivalent to about 3,000 miles on a car.

For example, a forklift with 5,000 hours on it roughly equates to a car with 75,000 miles.

Generally, the more hours a forklift has worked, the lower its price will be. However, hours alone don’t tell the full story.

The environment in which a forklift was used can significantly impact its condition.

For instance, 2,000 hours in a caustic chemical facility will cause far more wear than 2,000 hours in a facility that manufactures pillows.

For this reason, sellers often weigh the overall condition of the forklift more heavily than its hours when determining the price.

Supply & demand

Supply and demand greatly influence used forklift prices.

Some trucks – especially higher-capacity ones – are simply less available than more common “bread and butter” trucks, like 5,000 lb. cushion trucks (the archetypal “warehouse forklift”).

In contrast, when a dealer has an oversupply of a particular truck—such as after receiving multiple lease returns—they may offer these forklifts at discounted rates.

This situation can work to your advantage as a buyer.

Seasonal Demand

Timing your purchase can also affect price. For example:

- Pneumatic-tired trucks are popular for outdoor use in the spring and may cost more during that season.

- Cab trucks are in high demand during winter months.

If possible, plan your purchase during the offseason to secure better pricing.

Warranty

New forklifts typically include warranties ranging from one to five years. However, warranties for used forklifts are often shorter and vary greatly depending on the seller and the equipment’s condition.

Common warranty types include:

- “As-Is” Sales: No warranty, often sold at a discount but may require substantial repairs.

- Short-Term Warranties: 30- or 60-day parts and labor warranties.

- Powertrain Warranties: Six-month coverage for key components like the engine and transmission.

Warranty costs also vary, ranging from a few hundred dollars to $2,500 or more, depending on the lift, its hours, and how eager the seller is to close the deal.

Out-of-State Purchases:

If you’re buying a forklift from out of state, be aware that many dealers won’t offer a warranty.

It’s often too expensive and logistically difficult to service equipment outside their territory.

Paint

A fresh paint job and bodywork for a used forklift can add significant value, depending on the buyer’s needs.

For some operations, maintaining a forklift’s paint is essential to prevent contamination from paint chips, especially in industries with strict hygiene requirements.

Others invest in fresh paint to preserve the forklift’s integrity, as a well-maintained appearance often encourages operators to take better care of the equipment.

Regardless of the reasoning, if you’re considering a repaint, expect to pay between $1,000 and $2,000 for the job.

Attachment

Most forklifts come equipped with a side shifter as a standard feature.

However, some trucks may include additional attachments—such as paper roll clamps, box clamps, or other specialized tools—based on the application they were used for.

In some cases, sellers package the forklift with its attachment as a single unit, which can increase the total cost by thousands of dollars.

If you don’t need the attachment, it’s worth asking the seller if they’re willing to sell the forklift without it.

While some sellers might agree, others may not.

It doesn’t hurt to ask, and the savings could be substantial.

Negotiation

Negotiation is an integral part of the used forklift market, much like in the used car industry.

For buyers, this presents an opportunity to reduce the price or negotiate additional perks.

Depending on the seller, you may be able to secure “freebies” such as:

- A fresh coat of paint

- New tires

- An upgraded attachment

- Free shipping (especially for out-of-state purchases)

These extras can add up to significant savings—potentially thousands of dollars—making negotiation a valuable tool in your purchasing process.

Do Factors That Affect Forklift Price Affect Order Pickers and Pallet Jacks?

While many factors influencing forklift pricing also apply to order pickers and pallet jacks, there are key similarities and distinct differences to consider.

Similarities with Forklift Pricing Factors:

-

Capacity: As with forklifts, the weight capacity of order pickers and pallet jacks impacts their price. Higher capacities often require additional materials and engineering, leading to higher costs.

-

Fuel/Power Type: Electric models tend to be more expensive upfront due to battery costs, while manual options are typically more budget-friendly.

-

Features and Accessories: Customizations such as specialized attachments, ergonomic designs, and safety features can significantly influence pricing, much like with forklifts.

Distinct Factors for Order Pickers and Pallet Jacks:

-

Functionality: Forklifts are versatile, handling heavy lifting and transportation tasks. Order pickers and pallet jacks, however, are designed for more specialized purposes—order pickers for retrieving individual items from shelves and pallet jacks for moving pallets. Pricing reflects the unique functionalities of each.

- Size and Maneuverability: Compact designs make order pickers and pallet jacks ideal for navigating narrow aisles and confined spaces. Their size and weight are often pricing factors, reflecting their role in industries with specific layout requirements.

-

Load Handling: Unlike forklifts, which use forks for lifting pallets, order pickers often feature platforms or custom forks for individual item retrieval. Pallet jacks focus solely on pallet handling. Pricing is influenced by the specific mechanisms and capabilities of each type.

In Summary:

While many pricing factors overlap, the unique designs and specialized roles of order pickers and pallet jacks introduce nuances to their pricing. Understanding these distinctions is essential for making informed purchasing decisions based on operational needs and budgets.

Your Burning Question Finally Answered

Now that we’ve laid the foundation for understanding forklift pricing—both new and used—it’s time to explore the actual numbers.

Below is a rough range of prices for the most common types of forklifts.

How Much Does a New Forklift Cost?

Brand-new forklift prices can be tricky to pin down, as they are typically provided through a quote rather than openly displayed.

However, based on our records and experience, we’ve compiled a rough estimate of what you can expect to pay for the most popular forklift models and configurations across various brands.

To maintain an apples-to-apples comparison, we used these standard specifications:

- 187″ mast

- Battery and charger included with electric models

- 1-year basic warranty and 3-year powertrain warranty included for all trucks

New Forklift Price Ranges by Model:

| Truck Model | Price Range |

|---|---|

| 3,000 lb. Electric | $36,500-$39,500 |

| 3,000 lb. Cushion | $29,500-$32,000 |

| 3,000 lb. Pneumatic | $31,900-$33,500 |

| 5,000 lb. Electric | $37,000-$44,500 |

| 5,000 lb. Cushion | $35,000-$37,000 |

| 5,000 lb. Pneumatic | $38,500-$43,000 |

| 10,000 lb. Cushion | $68,500-$74,000 |

| 10,000 lb. Pneumatic | $77,000-$80,000 |

| 15,000 lb. Cushion | $105,000-$125,000 |

| 15,000 lb. Pneumatic | $105,000-$125,000 |

How Much Does a Used Forklift Cost?

Used forklift pricing is often more transparent, thanks to online marketplaces that openly list equipment for sale.

After analyzing 87 listings of the most common forklift types, we compiled pricing data for trucks that met the following criteria:

- Manufactured in 2010 or later

- 5,000 hours or less

- Mast height between 149″ and 200″

- Located in the United States

Here’s what we found.

Used Forklift Price Ranges by Model:

| Truck Model | Low Price | High Price | Average Price |

|---|---|---|---|

| 3,000 lb. Electric | $9,900 | $28,000 | $17,200 |

| 3,000 lb. Cushion | $9,900 | $28,000 | $18,200 |

| 3,000 lb. Pneumatic | $11,500 | $24,900 | $18,600 |

| 5,000 lb. Electric | $17,900 | $29,700 | $22,800 |

| 5,000 lb. Cushion | $17,800 | $29,700 | $22,900 |

| 5,000 lb. Pneumatic | $17,900 | $29,900 | $26,800 |

| 10,000 lb. Cushion | $24,500 | $47,800 | $32,600 |

| 10,000 lb. Pneumatic | $24,000 | $55,900 | $38,800 |

| 15,000 lb. Cushion | $46,000 | $79,900 | $61,800 |

| 15,000 lb. Pneumatic | $43,000 | $91,000 | $62,800 |

Keep in mind…

- Some of the used forklift listings included fresh paint in their price.

- None of the listings explicitly stated that a warranty was included.

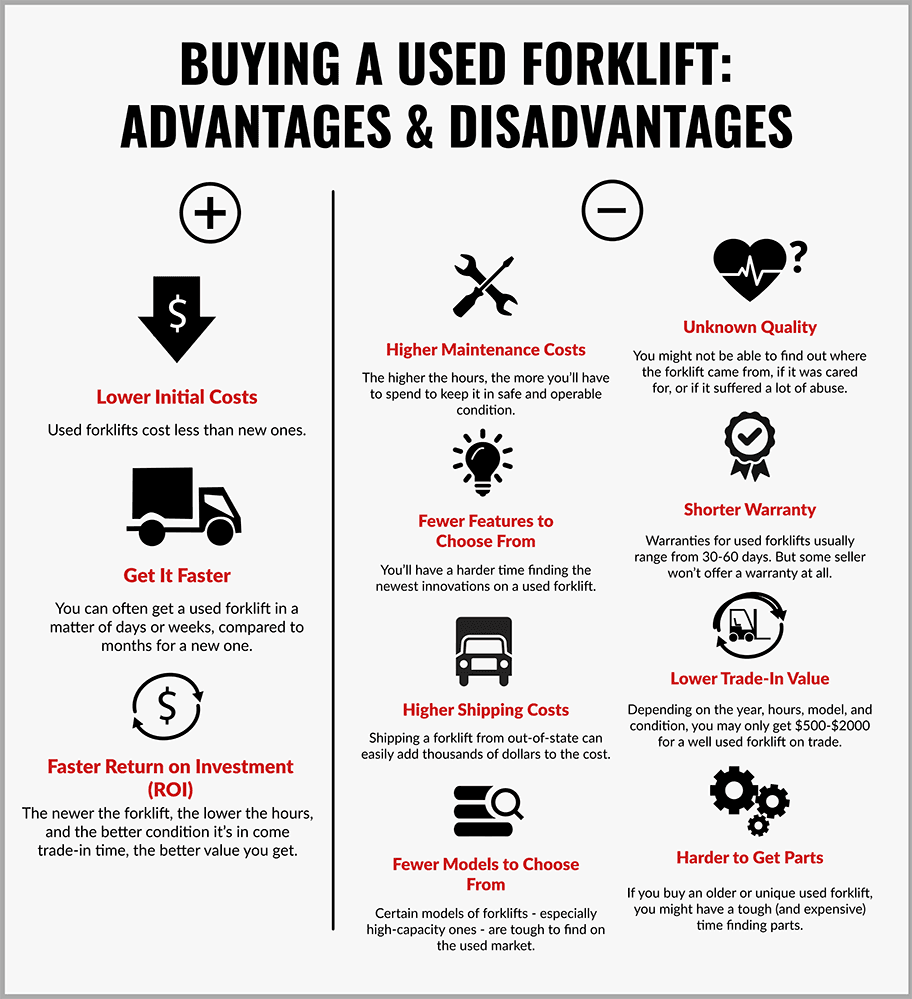

Do Not Just Compare Prices When Shopping for a New or Used Forklift

Now that you have an idea of the price ranges for both new and used forklifts, it’s important not to stop there.

Too often, price becomes the sole focus when shopping for a forklift, but there are other critical factors to consider.

To make the most informed decision, let’s explore the advantages and disadvantages of buying both new and used forklifts.

By the end of this section, you’ll understand why focusing solely on price could lead to a costly—and avoidable—mistake.

To explore those other factors, let’s examine the various advantages and disadvantages that come with buying both new and used forklifts.

Once we’ve run through them, you’ll see exactly why you shouldn’t fixate only on price when making your decision.

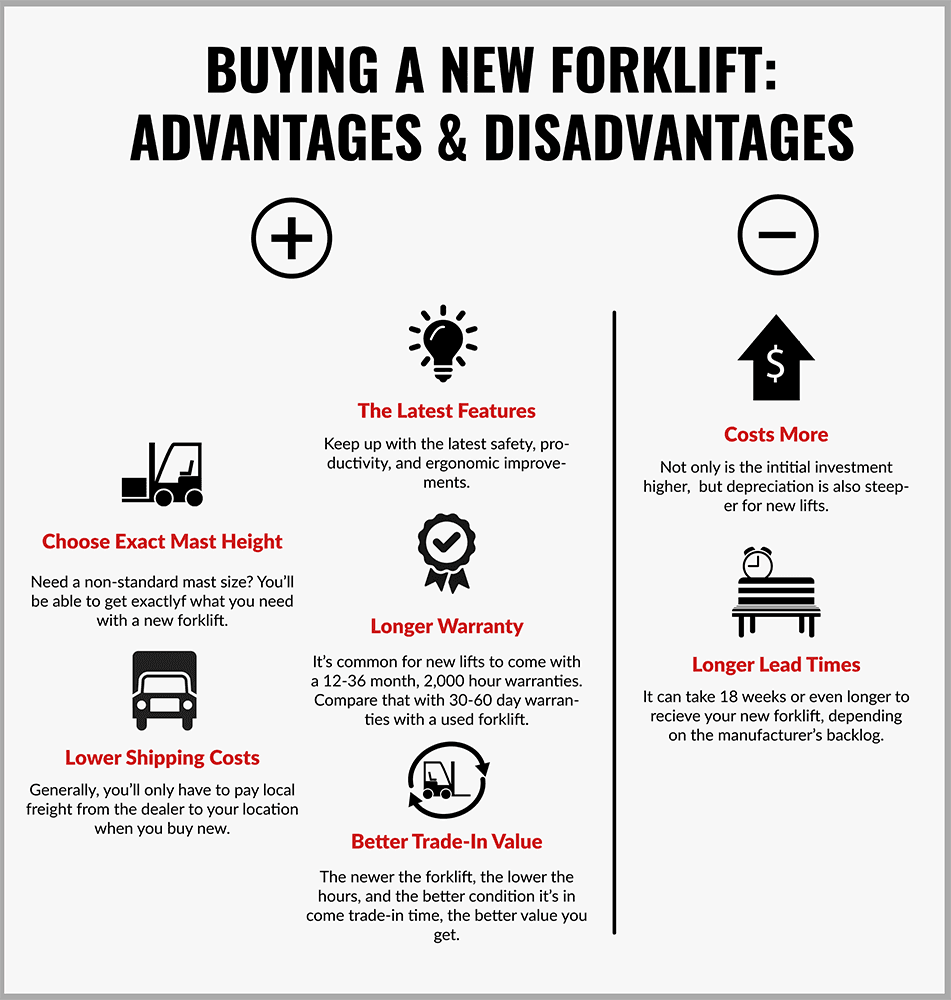

Buying a New Forklift: The Advantages

Although a new forklift comes with a higher price tag, there are several compelling reasons to consider this option.

Get the Latest Features

Just like cars, forklifts are continually updated with improved technology and features.

These updates may include:

- Integrated dashboards with onboard diagnostics

- Enhanced safety features

- Better emission controls

- More comfortable operator compartments

By purchasing new, you gain access to the latest innovations, helping your operation run more efficiently, with less downtime and a reduced risk of operator injury.

Customize the Mast Height

If your operation involves tall racking or confined spaces (e.g., semi-trailers or railcars), you may require a non-standard mast height.

Buying new offers the flexibility to choose the exact mast size you need, a feature that’s often hard to find in the used market.

Lower shipping costs

When you buy new, shipping costs are typically limited to local delivery charges, as forklifts are sent to the dealership for inspection and any customizations.

If you have the resources, you can further reduce costs by picking up the truck directly from the dealership.

In contrast, buying used—especially from an online seller—can result in hefty shipping fees.

Longer warranty

As previously mentioned, new forklifts often come with warranties ranging from 12 to 36 months or up to 2,000 hours.

Used forklifts, on the other hand, typically offer much shorter warranties (30 to 60 days) or none at all.

Better trade-in cost

The logic is simple: A truck that’s 5 years old with 5,000 hours on it is probably going to be worth more when traded in than a truck that is 10 years old with 10,000 hours on it.

A newer forklift with lower hours will typically fetch a higher trade-in value compared to an older, heavily used model.

If you plan to trade in your forklift after a few years, buying new can result in a better return on investment—provided the equipment is well-maintained and not subjected to harsh conditions or operator abuse.

Buying a New Forklift: The Disadvantages

While the advantages of buying new are significant, it’s important to weigh the downsides.

Higher Initial Cost

The most obvious drawback is the cost. As shown in the price ranges earlier, new forklifts are significantly more expensive than used ones.

- The initial investment is higher.

- Depreciation occurs quickly, much like with a new car, as the forklift’s value begins to drop once it’s delivered.

However, if you plan to keep the forklift for its entire lifespan, depreciation may be less of a concern.

Longer Lead Times

New forklifts typically require a waiting period between the time you place your order and delivery.

Lead times can range from several weeks to as long as 18 weeks, depending on:

- The manufacturer’s production schedule

- Order volume

- Customizations requested

If you need a forklift quickly, this delay might make buying used a more practical choice.

Immediate Availability

If you’re in urgent need of a forklift, the waiting period for a new truck may not be feasible.

However, many dealerships offer rental trucks at discounted rates while you wait for your new forklift to arrive.

Buying a Used Forklift: The Advantages

While we’ve covered the perks of buying new, there are several compelling reasons to consider buying used.

Lower Overall Cost

Used forklifts are almost always less expensive than new ones, making them an attractive option for budget-conscious buyers.

If you’re currently renting a forklift and decide to purchase it, you might even negotiate a discount based on the rent you’ve already paid—depending on the dealership.

Additionally, buying used provides opportunities to negotiate not just the price, but also potential upgrades, such as larger forks, new tires, or advanced attachments like a side shifting fork positioner instead of a standard side shifter.

Faster Availability

A used forklift is typically available much sooner than a new one.

In some cases, you can take delivery within days, compared to the months-long lead times for new forklifts.

If you’re renting a forklift and wish to purchase it, the process is even quicker—you could own it outright immediately.

Faster ROI

The sooner you receive your forklift, the sooner you can put it to work and start generating returns. This faster turnaround helps you recoup your initial investment more quickly.

Buying a Used Forklift: The Disadvantages

While used forklifts offer significant benefits, it’s important to consider the potential downsides.

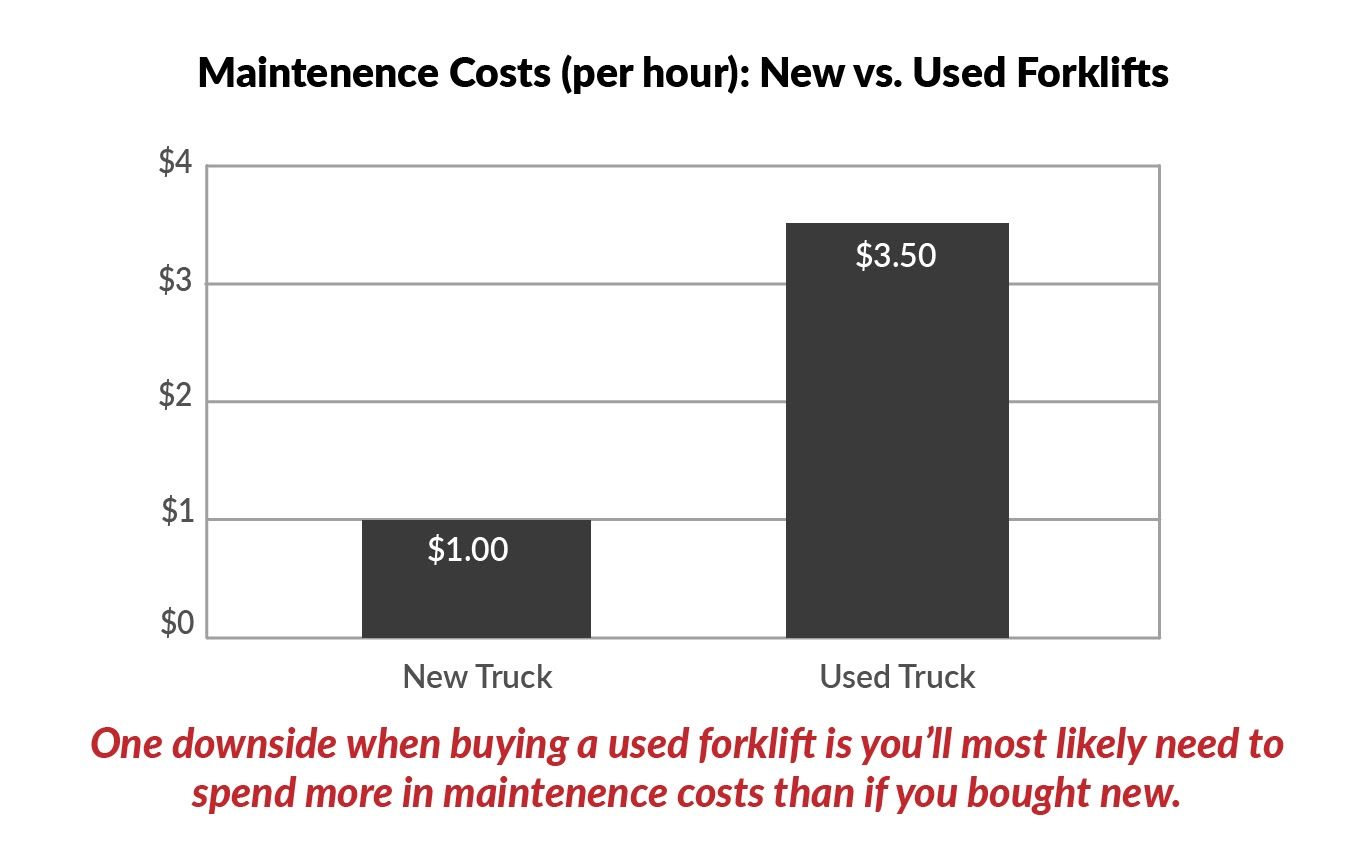

Higher maintenance costs

Used forklifts typically have higher maintenance costs due to wear and tear.

Older forklifts or those with higher hours are more likely to need repairs, increasing operational expenses.

Even if purchased from a reputable seller, there’s always a chance of unexpected breakdowns once the forklift is in operation.

Limited Features and Configurations

When purchasing a used forklift, finding the exact configuration and features you need can be challenging.

Specialized features such as heated cabs for outdoor use, 4-way hydraulic valves for accommodating clamps and attachments, or LPS and EE-rated forklifts for hazardous environments are harder to come by in the used market.

Additionally, the condition of the forklift—and how much effort the seller has put into refurbishing it—can vary significantly.

Some sellers barely inspect the forklifts they acquire, offering them “as is” with minimal or no repairs.

These forklifts, often priced as low as $3,000 on sites like eBay, Craigslist, or auction platforms, frequently show clear signs of neglect, such as rust, worn tires, or damaged components.

While these may seem like bargains, they often require significant repairs, which can quickly drive up costs.

Less selection of certain types of models

Some forklift models are simply harder to find in the used market due to their limited production or specialized applications.

For example:

- 15,500 lb. cushion forklifts: These are produced in smaller quantities and are rare on the secondary market.

- High-capacity forklifts with tall masts: These are typically custom-ordered for specific tasks, making them scarce as used equipment.

- Specialty forklifts: Articulating narrow aisle models (e.g., Aisle Masters or Flexi’s) and multi-directional forklifts (e.g., Combilifts) are also uncommon in the used market.

So, if you need these types of forklifts, you may end up having to bite the bullet and buy new.

Unknown quality

When buying used, the history of the forklift is not always transparent.

Without proper service records, you could unknowingly purchase a forklift with:

- A history of poor maintenance

- Damage from harsh environments (e.g., chemical plants, concrete factories, or food processing facilities)

- Repairs performed by unqualified technicians

- Batteries that have not been properly maintained (for electric models)

To minimize these risks, always request service records and, if possible, investigate the forklift’s previous application.

If the truck was used in a high-stress environment, it may be best to pass.

Increased costs of shipping

So, you’ve found a great deal on Craigslist (or eBay, or Equipment Trader), but did you factor in shipping?

Transporting a forklift interstate or cross-country can range from $1,000 to $5,000 or more.

For oversized or heavy equipment requiring special permits, these costs can escalate further.

Always include shipping in your total cost calculation when buying online.

Shorter warranties

When browsing online equipment sites, you won’t often find any mention of a warranty.

That’s because it’s much more expensive for a dealer to try to service a tow motor that’s sold to a customer who’s out of state.

Warranties for used equipment usually range from 30 to 60 days.

Unless buying out of state, that is – sellers generally don’t provide warranties in that case.

If you want an extended warranty, be prepared to pay more.

Working with a reputable local dealer can help ensure at least a short warranty, but it won’t match the coverage of a new forklift.

Lower trade-in cost

If you purchased a used forklift and put a ton of additional hours on it, chances are good you’re only going to get a fraction of what you paid for it in trade-in value.

Here’s a rough set of guidelines for typical trade-in values for well-used forklifts:

- 5,000 lb. capacity or less internal combustion forklifts will bring $800 to $2,000.

- 5,000 lb. capacity or less electric forklifts are worth $1,000 to $1,500 (if the battery is included, which accounts for most of the value).

- 10,000 lb. capacity and up internal combustion forklifts can bring a couple of thousand dollars.

Scrap values for electric and internal combustion forklifts alike are based on weight, and rise and lower with the market price of steel – but you won’t usually get more than a few hundred dollars.

In contrast, a newer forklift with lower hours may retain up to two-thirds of its original value when traded in after a few years, provided it’s in good condition.

Greater difficulty getting parts

Older forklifts or rare models can make finding replacement parts difficult and expensive. Some parts may only be available overseas, increasing both shipping costs and delays.

Before purchasing a used forklift, check the availability of replacement parts and ensure they are reasonably priced and accessible.

And if you do manage to find them, be prepared to spend extra to get them.

That’s both in terms of the parts themselves and extra shipping costs, as sometimes the parts are only available overseas.

How to Choose Between New and Used

Alright, we’re at the end of the road.

Before diving into the final steps of making your decision, let’s quickly recap the key points we’ve covered:

- Price ranges: What you can expect to pay for new and used forklifts.

- Factors influencing cost: What drives prices up or down for both new and used models.

- Beyond the price tag: Why cost isn’t the only consideration when shopping for a forklift.

- Pros and cons: The major advantages and disadvantages of buying new versus used.

Now it’s time to bring everything together and outline a decision-making process tailored to your material handling needs and budget.

To make the best choice, ask yourself these key questions:

- What does your operation need?

- How long will a new or used forklift serve you?

- Does the option you’re considering make financial sense?

Let’s get started.

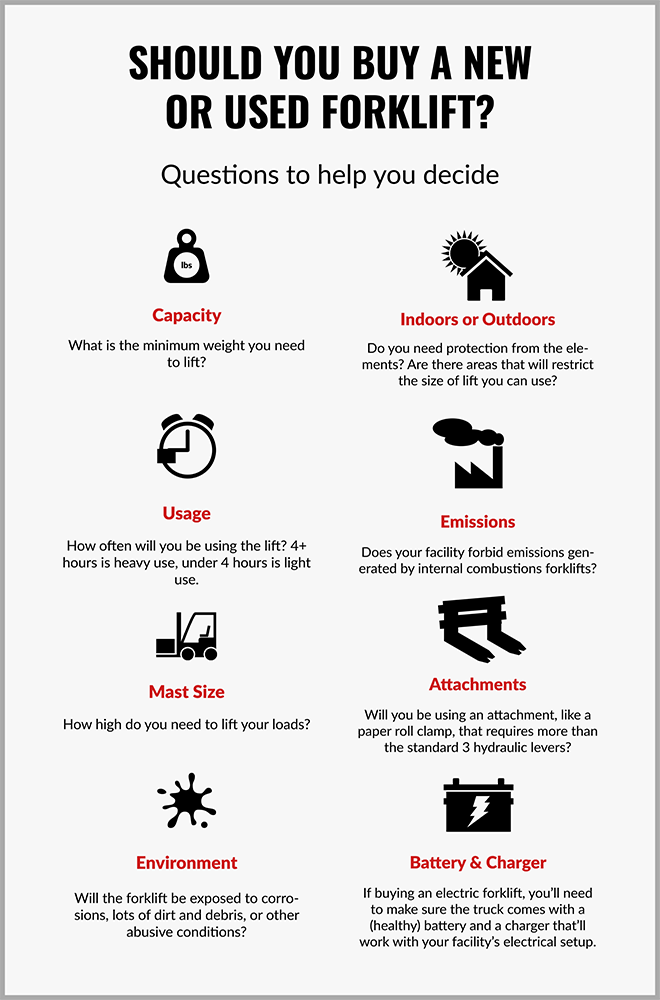

What Do You Need?

The first step in choosing the right forklift is to evaluate your operation and determine which type of forklift will meet your needs.

With that in mind, let’s break down the key questions to consider.

Capacity?

What lifting capacity does your operation require?

Do you need a smaller, 3,000 lb. lift for light-duty tasks in your warehouse?

Or does your facility demand a heavy-duty 30,000 lb. diesel forklift for more intensive work in a fabrication environment?

Capacity is one of the first—and most critical—questions to answer when shopping for a forklift.

As we mentioned earlier, high-capacity trucks are harder to find on the used market, so availability may play a big role in shaping your options.

Mast size?

What mast size is suitable for your application?

Here are some common mast sizes:

- 131″

- 171″

- 189″ (the standard size)

- 199″

- 200″

- 210″

- 240″

For standard-capacity used forklifts (3,000 lb. to 10,000 lb.), finding a standard 189″ mast isn’t usually a challenge.

However, specialty sizes—like a 370″ mast for a used reach truck—may be more difficult to locate.

Heavy use?

How much will you be using the forklift each day?

If your forklift will see 4 or more hours of use daily, that qualifies as “heavy use.”

In such cases, you may want to prioritize newer models with fewer hours on them to ensure they can withstand the extra wear and tear.

If you’re considering a used forklift, keep in mind that the significance of operating hours varies with the truck’s capacity.

For higher-capacity forklifts, higher hours are more impactful, so choose accordingly.

For example, 10,000 hours on a 15,500 lb. truck is far more taxing than 10,000 hours on a 3,000 lb. electric 3-wheel forklift. While the electric model may keep running under proper care, the heavier truck could be nearing the end of its life.

To maximize value, aim for forklifts around the 5,000-hour mark. That’s typically when dealerships convert their rentals into used inventory, offering a good balance of remaining life and cost.

Environment?

Tough Conditions

Will the forklift operate in an environment with corrosive chemicals, dust, or debris? If so, evaluate whether a used forklift can perform well under these conditions.

If not, consider:

- A low-hour used forklift for durability.

- A near-end-of-life forklift as a cost-effective, disposable option.

Outside or inside?

Outdoor use: Do you need a cab? If a used forklift with a cab is unavailable, get a quote for an aftermarket cab installation and weigh the cost against a new model with a factory-installed cab.

Indoor use: Check for short doorways, narrow aisles, and emission requirements. Electric forklifts are essential for emission-sensitive environments like medical or food facilities.

What type of attachment do you need?

Before buying a forklift, it’s important to figure out which attachment best suits your needs.

Most new and used trucks come with a sideshifter as a standard feature—so it typically won’t add to your total cost.

But if you need something more specialized, like a fork positioner, paper roll clamp, or a single-double attachment, you’ll want to know that upfront.

Once you’ve identified the right attachment, make sure that any forklift (new or used) is already equipped with the proper hydraulic setup—specifically the hosing and control valve—to handle that attachment.

Retrofitting a truck that wasn’t designed for a particular attachment can be very costly, running $4,000 or more depending on the model and mast size.

You’ll also want to check that the attachment’s capacity and class size are compatible with the forklift you choose.

Keep in mind that the attachment’s rating will set the overall lifting capacity.

For instance, if your forklift is rated at 10,000 lb. but the attachment can only handle 7,250 lb., then 7,250 lb. becomes the actual lifting capacity of the truck.

What about the battery?

Batteries for new and used electric forklifts are handled a bit differently.

When you’re buying a new electric truck, the battery is usually sold separately.

The reason is that the major forklift manufacturers (Toyota, Hyster/Yale, Mitsubishi/Caterpillar, UniCarriers, etc.) don’t make batteries.

That’s left to companies like GNB, Hawker, and Enersys.

While this gives you more choice in features and specs, it also means an extra cost—often between $5,000 and $12,000 or more for a new battery.

For used electric forklifts, sellers often include whatever battery they have in stock, which can limit your choices in terms of year, manufacturer, configuration, and so on.

In some cases, no battery is included at all.

Because a used electric forklift might come with a battery in questionable condition, be sure to ask if it’s included in the sale.

Then, ask for the make and year of the battery.

A battery should last roughly 5 years (if maintained and not used excessively).

Next, find out the battery’s make, year, and tested capacity.

Dealers typically offer batteries at around 80% capacity, which translates to about four hours of run time before needing a recharge.

If four hours of runtime doesn’t meet your needs, if the battery is older (pushing four or five years), or if you’re simply not comfortable with a used battery, consider buying a new one.

You also might be able to negotiate a deal by having the seller subtract the used battery’s cost or by lowering the overall price on the truck.

And if you’re wondering, “What are some used forklift battery prices?” the answer is anywhere from $1,000 to $5,000, depending on the size and capacity you need.

What about the charger?

Chargers follow a similar pattern: new chargers are usually sold separately, and used chargers may or may not be included with a used forklift purchase.

Always verify whether a charger is included if you need one.

Specialty chargers—like opportunity chargers, multi-volt chargers, or 110-volt chargers—are sometimes harder to find on the used market without paying extra.

As for costs, new chargers can run from $3,000 to $6,000 or more, while used chargers typically range from a few hundred dollars up to $1,500 or more, depending on condition and features.

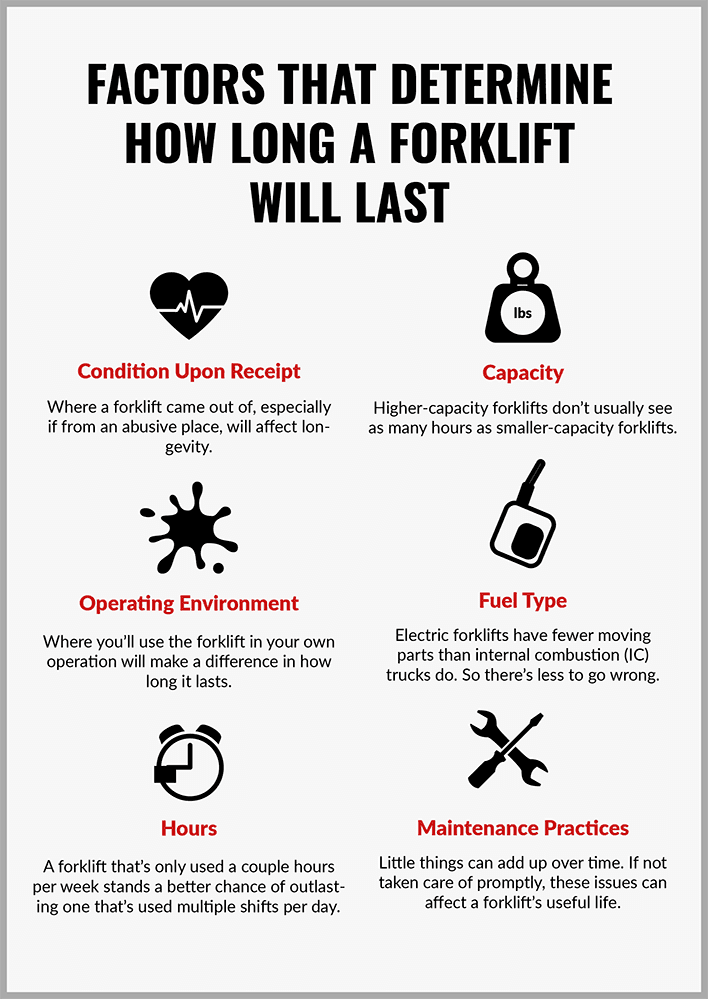

How Long Will a New or Used Forklift Last?

When deciding whether to buy new or used, it helps to know how long a forklift can be expected to last.

A good rule of thumb is that, with proper maintenance, the average forklift in an average operation can reach around 10,000 hours of service.

Some brands, like Toyota, are known for even greater longevity—15,000, 20,000, or in some cases 30,000+ hours for LPG models, and 50,000+ hours for electric models, when properly maintained.

Of course, any number of factors can extend or reduce a forklift’s useful life, including the type of work it performs, how often it’s serviced, and whether it’s used indoors or outdoors.

Ultimately, the question to ask yourself is: “Will this forklift last me long enough to justify what I’m paying for it?”

If the answer is yes, a used forklift might be the perfect fit.

If you need the peace of mind and guaranteed longevity of a new truck, spending more upfront could be well worth it.

Electric Forklifts Last Longer

Whether new or used, electric forklifts typically outlast their internal combustion counterparts.

That’s largely because they have fewer moving parts, so there’s less to maintain.

Of course, the battery will eventually need replacing—which, as you know, can be quite costly.

The Shape You Got It In

When buying new, you won’t have to worry about previous wear and tear.

But if you’re purchasing used, you’ll want to pay close attention to the forklift’s history.

Was it well-maintained?

Did it operate in a rough or abusive environment?

Did the seller perform a thorough condition report and fix any issues before selling?

Operating environment

Just as the forklift’s past environment matters, so does the one you’re about to place it in.

Corrosive, dirty, or debris-filled areas—or places with extreme heat, cold, or moisture—can lead to frequent breakdowns and a shorter useful life.

To maximize longevity, reduce exposure to harsh conditions whenever possible.

Hours used

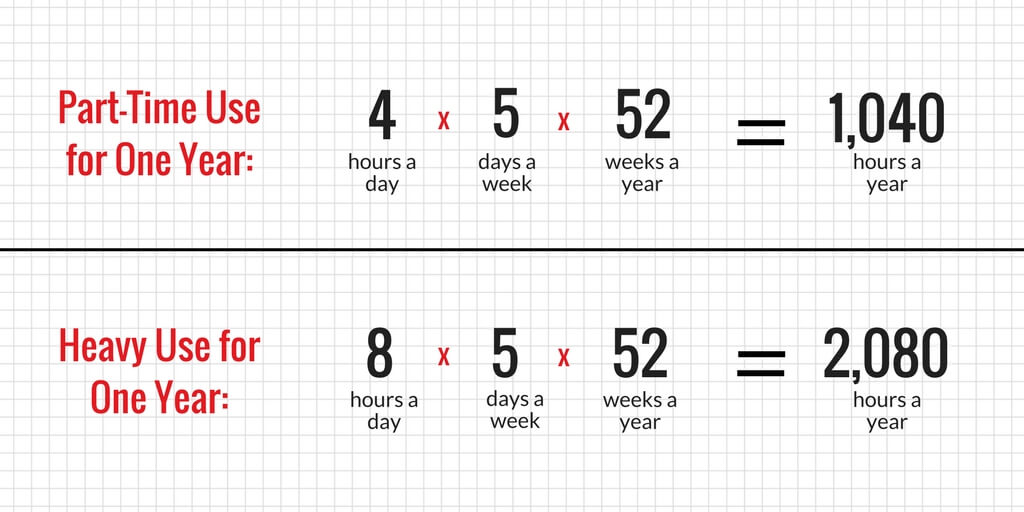

“Heavy use” typically means running a forklift four or more hours each day.

The more hours it’s in operation, the more wear and tear you’ll see—which shortens its lifespan and increases maintenance costs.

Two shifts per day will obviously rack up hours (and repairs) faster than a single 4-hour shift.

Maintenance practices

Regularly maintaining the truck is essential to extending its life.

Ignoring small issues—like worn tires or underperforming batteries—can lead to bigger (and more expensive) problems later on.

Skipping recommended repairs might save money in the short term, but it increases the likelihood of costly breakdowns and potential safety issues down the road.

Operator behavior

How your operators use the truck directly impacts its lifespan.

Overuse of the inching pedal, for instance, can damage the transmission over time.

Collisions or rough handling often lead to expensive structural repairs, especially to the mast, drive axle, or steer axle.

If you can’t rely on proper operator practices, expect the forklift to wear out sooner.

Capacity

Higher-capacity forklifts generally have shorter lifespans than smaller-capacity models because they’re used in more demanding environments.

Repairs on larger trucks are also pricier, which can make it more cost-effective to replace them earlier than you would a lighter-duty truck.

What to Look for When Buying a Used Forklift

When shopping for a used forklift, weigh factors such as age, service hours, application history, and overall condition.

Decide if you want to minimize upfront costs or prioritize high-quality components and reliability.

And for a quick rundown of what to look for, check out the video below!

FORKLIFT AGE

If you’re trying to save money, consider equipment that’s at least five years old.

Any newer and you may end up paying closer to the original value than you’d like.

TOTAL HOURS

A used forklift’s hours are measured in two ways: key hours and usage hours. Many models track both and display them on the dashboard.

- Key hours accumulate whenever the key is turned on—even if the forklift is idling. Because the machine isn’t actively operating during idle time, key hours aren’t always a reliable indicator of wear.

- Usage hours offer a more accurate depiction of how often the forklift was actually working. For instance, they might track driving, operating the pump, or lifting. In a standing model, usage hours may tally whenever the operator depresses the pedal. In sit-down units, they may be recorded via a seat switch that’s triggered when the operator sits.

How many hours should your used equipment have? When looking for used equipment, part-time use is best.

Much like a car’s mileage, higher hours can mean more wear and tear—particularly on parts like the hydraulic motor and lines.

APPLICATION HISTORY

Forklifts that operated in extreme environments often show more wear. Previous conditions to watch out for include:

- Proximity to salt water: Causes accelerated corrosion.

- Extremely cold climates: Can make engine and hydraulic seals brittle.

- Very humid settings: Moisture can reach electrical systems and lead to corrosion.

- Heavy outdoor use: More exposure to the elements means faster wear and tear, including rust.

CONDITION

Before making a purchase, inspect the condition of any used forklift.

Ideally, have a certified technician evaluate it as well.

Key areas to examine include:

- Forks: Look for cracks, bent blades, or uneven blade heights.

- Lift Chains: Check for excessive gaps between links. If in doubt, have a technician measure them with a chain gauge.

- Safety Elements: Verify that seatbelts, lights, and the horn are functioning correctly.

- Mast: Ensure it operates smoothly with and without a load, without any slippage.

- Tires: Inspect for chunking, radial cracks, and tread depth. Poor tire maintenance can cause further damage to the forklift.

- Engine: Confirm that it starts easily. For diesel forklifts, watch for minimal exhaust.

- Leaks: Check around the mast, tilt cylinders, transmission, and radiator after the forklift warms up.

USE CAUTION WHEN BUYING USED

Before committing to a used forklift, note a few potential red flags that could signal future challenges:

- Maintenance History: If you can’t verify how previous owners serviced the forklift, be prepared for unexpected costs. Reputable dealers often provide records detailing past maintenance and application history. If that’s not available, signs like fluid leaks or difficulty starting may indicate poor upkeep.

- Models Out of Production: Avoid forklifts no longer in production; it can be tough to find affordable replacement parts.

By working with a reputable dealer, you’ll reduce your risk when buying used equipment.

How long will YOUR forklift last?

Now that you understand the factors that affect a forklift’s lifespan, think about your specific situation and environment.

Ask yourself how each factor might impact the forklift you plan to put into service, and be honest with yourself—expect real-world scenarios.

It’s easy to assume your forklift will only operate in ideal conditions with careful operators and regular maintenance, but things don’t always work out perfectly.

When in doubt, consult a qualified professional at your local dealership.

They’ll take a second look at your material handling operation, make sure you’ve considered all relevant factors, and help you estimate how long your forklift might realistically last.

Once you have a clear picture of how the environment and maintenance routine will affect your forklift, you can decide whether buying new or used makes the most financial sense.

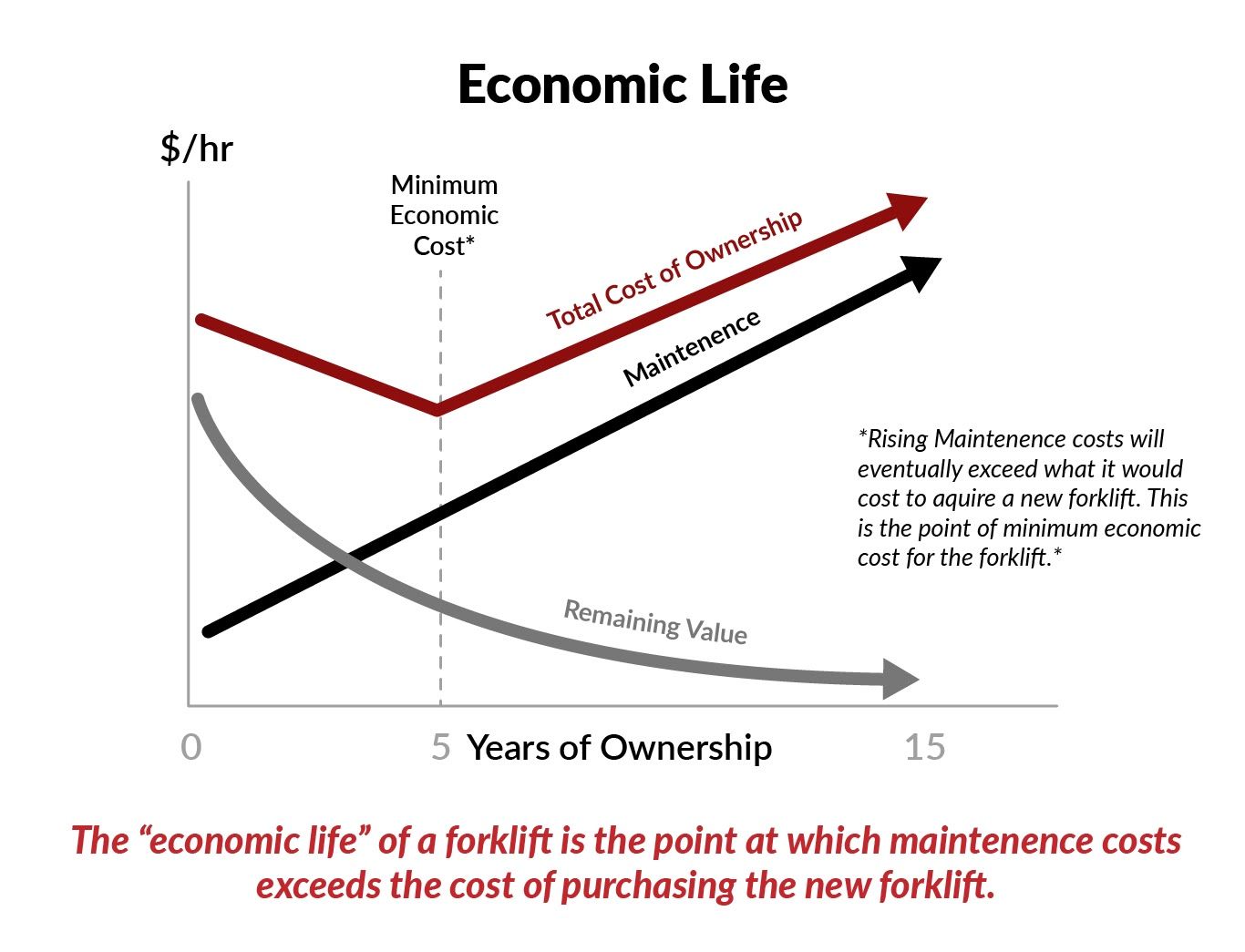

Does it Make Financial Sense? How to Calculate the Economic Life of Your Forklift

Now that you know how long a forklift can last, the final step is figuring out whether it’s more cost-effective to repair or replace it. This is where the concept of a forklift’s economic life comes in.

What does the “economic life” of a forklift mean?

Put simply, the forklift’s economic life is the point at which maintenance and repair costs become higher than the cost of replacing the machine.

Understanding this number helps you decide if buying new or used will give you the best return on investment.

Calculating the Economic Life: An Example

Let’s walk through an example of how to determine a forklift’s economic life so you can do the same for your operation.

Say you find a used 5,000 lb. pneumatic forklift for sale. It’s currently got 7,000 hours on it. And using what you’ve read in our post here, you feel it’s a good price for the offer.

Find a Used Forklift

Suppose you come across a 5,000 lb. pneumatic forklift with 7,000 current hours on its meter.

Based on your research (including what you’ve learned in this guide), you feel it’s fairly priced.

Estimate the Forklift’s Usable Hours

Generally, many forklifts can run up to 10,000 hours.

But in your unique environment, you estimate you can get about 9,000 hours out of this one. That leaves roughly 2,000 hours of usable life.

Here’s how you can take that information, and use it to determine the economic life of the forklift.

Project Daily and Annual Usage

- Let’s say you plan to run the forklift 4 hours per day.

- You operate 5 days a week (about 260 working days per year).

-

Run the Numbers

- Subtract the forklift’s current hours (7,000) from your projected final hours (9,000).

- That gives you 2,000 hours of remaining useful life.

- At 4 hours per day, 5 days a week, you’ll reach that threshold in about 1.9 years, according to a standard economic life calculator.

Where to Buy a Forklift: Your Options Explained

Now that you understand the key aspects of buying a new or used forklift, the next step is deciding where to make your purchase.

There are three main options to consider:

- Buying online from industrial equipment sales websites.

- Purchasing from individual companies selling their forklifts.

- Working directly with a dealership.

Let’s break down each option to help you choose the best fit for your needs.

Buying online from an equipment sales website

Many websites specialize in industrial equipment sales, including:

- IronPlanet.com

- LiftsToday.com

- EquipmentTrader.com

These platforms often feature forklifts listed by dealers seeking greater visibility for their inventory.

This approach broadens your selection beyond local options, making it easier to find specialized or uncommon equipment.

Advantages:

- Greater variety: Access to forklifts from across the country.

- Specialized options: Better chances of finding unique or specific models.

Disadvantages:

- Unknown sellers: You may not be familiar with who you’re buying from.

- Limited inspection: Evaluating the forklift’s condition is often restricted to photos or videos.

- High shipping costs: Transporting equipment from out of state can be expensive.

Buying from individual companies

Another option is to purchase directly from businesses selling their forklifts, either locally or online.

For example, companies going out of business may need to sell their equipment, or liquidation firms may acquire forklifts as part of their inventory.

Advantages:

- Lower prices: Sellers are often motivated to offload equipment quickly, sometimes at a reduced price or even a loss.

Disadvantages:

- Uncertain quality: You likely won’t receive a service history or warranty.

- Risk of hidden issues: Without a professional evaluation, you’re taking a gamble on the forklift’s condition.

Buying from a dealership

Your final option is purchasing from a local forklift dealer.

As a dealership ourselves, we’re admittedly partial to this route. But the benefits of working with a dealer are compelling and worth considering.

Speak with your local Conger dealer if you are in (Green Bay, Neenah, Wausau, Richfield, or any other nearby town/city)

Key Benefits of Buying from a Dealer

-

Inspect Before You Buy

Buying locally allows you to see the forklift in person, inspect its features, and even test it. This hands-on experience helps ensure the equipment meets your operational needs. -

After-Sales Support

Dealers often provide warranties and dedicated after-sales support. If issues arise, technicians can diagnose and repair the equipment, saving you time and frustration. -

Professional Sourcing

Need something specific? Dealers can leverage their networks to source the right forklift, inspect it, make any necessary repairs, and deliver it to you in excellent condition. This eliminates the logistical headaches often associated with working with distant sellers. -

Expert Guidance

A dealer’s sales team can offer tailored advice, visiting your facility to assess your operational needs and ensure the forklift is a perfect fit. This level of expertise can prevent costly mistakes and ensure a smooth purchasing experience.

Choosing where to buy your forklift depends on your priorities.

Online platforms offer variety, individual sellers provide potential cost savings, and dealerships deliver peace of mind and comprehensive support.

While each option has its merits, we believe factory-authorized dealerships, like Conger, offer the most reliable and hassle-free path to finding your next forklift.

Speak with your local Conger dealer if you are in (Green Bay, Neenah, Wausau, Richfield, or any other nearby town/city)

Conclusion

Navigating the forklift market—whether you’re considering new or used models—can seem daunting at first glance.

However, with a comprehensive understanding of the various pricing factors, benefits, and drawbacks associated with each option, you’re now equipped to make an informed decision that aligns with your operational needs and budget.

Key Takeaways:

-

Price is Just the Beginning: While cost is a significant factor, it’s essential to evaluate other critical elements such as lift capacity, fuel type, mast size, and the specific features that your operation requires. These factors not only influence the initial price but also affect the forklift’s long-term performance and maintenance costs.

-

New vs. Used Forklifts:

- New Forklifts offer the latest technology, customization options, longer warranties, and higher trade-in values. They are ideal for operations that demand reliability and advanced features, and are willing to invest more upfront for these benefits.

- Used Forklifts present a cost-effective alternative with lower initial expenses and quicker availability. They are suitable for businesses with tighter budgets or those needing forklifts immediately. However, it’s crucial to consider potential higher maintenance costs and limited warranty options.

-

Assessing Lifespan and Economic Life: Understanding how long a forklift will serve your operation is vital. Whether opting for new or used, consider the forklift’s expected lifespan, the intensity of its use, and how maintenance practices will impact its durability. Calculating the economic life of your forklift ensures that your investment remains financially sound over time.

-

Choosing the Right Purchase Channel:

- Dealerships like Conger provide the advantage of thorough inspections, warranties, expert guidance, and after-sales support, ensuring a reliable and hassle-free purchasing experience.

- Online Platforms and Individual Sellers offer broader selections and potential cost savings but come with increased risks regarding quality and support.

Final Thoughts:

Selecting the right forklift is a strategic decision that impacts your operational efficiency, safety, and financial health.

By carefully weighing the pros and cons of new versus used forklifts, evaluating your specific needs, and choosing a reputable purchase source, you can secure equipment that not only meets your immediate requirements but also supports your long-term business goals.

Remember, the right forklift is more than just a purchase—it’s an investment in your company’s productivity and success.

Take the time to assess your options thoroughly, consult with experts, and prioritize quality and reliability to ensure that your forklift serves you well for years to come.

If you’re ready to explore your options further or need personalized assistance, don’t hesitate to reach out to your local Conger dealer in Green Bay, Neenah, Wausau, Richfield, or any nearby area.

Our team is here to help you find the perfect forklift solution tailored to your unique needs.