Implementing lean management principles is challenging.

The goal? To eliminate waste without sacrificing productivity to improve customer value.

When it comes down to applying lean strategies, it’s not so easy.

So we asked six Toyota experts: how are you applying lean management principles at your facility?

The insights we received were nothing short of amazing. They’re all listed below:

THIS IS KAIZEN CULTURE: EVERYONE, EVERY DAY, EVERYWHERE

Scott Redelman | National Manager of Toyota Lean

“This is difficult to answer because you’re really asking me, “How do you breathe”?

Everything Toyota does – talent management, planning, product development, problem solving – all areas of the business are infused with lean principles – the utopia being total elimination of waste and 100% customer satisfaction.

This is Kaizen culture: Everyone, every day, everywhere.”

To put it in terms of how Toyota’s Lean Management journey is furthered through the Toyota dealer network:

“The objective of the Toyota Lean Management journey with our participating dealers is to enhance the culture and tools made globally famous by the Toyota Production System in our customer facing channels.

The journey starts in dealer operations, working on 5S, visual management, and quality improvement, leveraging a “Kaizen” or continuous improvement culture.

Later we transition the activity to dealer sales in order to engage and advise interested customers on their own lean journeys. We believe this is a special value add for our customers that only the Toyota family can offer and we are happy to share our lean experience with interested customers in any industry.”

MAKE INVISIBLE PROBLEMS VISIBLE

Simon Walker | Cheif Operating Officer and Lean Champion

Toyota-Lift

“Toyota Lean Management is the system we use to improve our business practices every day. We use problems and problem-solving as powerful opportunities for learning and performance improvement. To do this, we first need to make invisible problems visible.”

“We start with identifying an area in which we think we can do better. We define the problem as succinctly as we can by articulating the gap between the current state and the desired state.

We believe that if we define the problem well, we are half way towards solving the problem.

Our approach is to focus on who is responsible versus who is in charge. Responsibility can be shared; being in charge does not allow for contribution and collaboration.

By defining who is responsible, we are able to start collecting the facts to start solving the problem. Problem ownership, therefore, is how we empower our team to get decisions made and create the possibility for meaningful change.”

ASKING WHY IN LEAN MANAGEMENT

“When collecting data to solve a problem, we ask “why” over and over until we believe we have arrived at the root cause.

We are concerned with why, but we do not ask who. “Who” would dilute the sense of shared responsibility to solve the problem. We do not personalize problems – because we believe people are rarely the source of a problem.

The Toyota way is to find the process that does not work, implement the new process, and retrain.”

MONITORING IMPLEMENTATION

“Once we have created the counter-measures to address the problems, we also decide upfront how we will monitor their implementation. Who will follow up with a by-when, is crucial in the Plan-Do-Check-Adjust cycle.

The PDCA cycle ensures that counter-measures are being implemented correctly. If the execution of the counter-measure is appropriate but the results are not where we need them to be, we adjust the counter-measures along the way, restarting the PDCA cycle.

Toyota Lean Management is a management philosophy that teaches team members how to solve problems in a way that is effective and sustainable.

By surfacing the problems and then thinking through how to solve the problems, we teach the team how to think and take responsibility.

If the team can think critically when approaching problems, and those problems are resolved effectively, we have done more than simply problem-solve. We have developed a performance culture that gets results for the benefit of the company and our customers.

In effect, we have created leaders, who then continue to strengthen our leadership position in the market place.”

TOYOTA LEAN MANAGEMENT IS ABOUT PROCESSES, BUT IT’S REALLY ABOUT RESPECT

Robert Payne | Assistant Parts Manager & Lean Champion

Toyota Material Handling Mid South

“I know TLM is about processes, but in the end it is all really respect for people. We have to respect each other and be aware and mindful of how our departmental processes affects the next department down the line because in the end, it all makes its way to the customer. That goes for the time wasting processes and the time saving processes alike.”

Robert gives three specific examples of how they’ve used Toyota Lean Management in their parts department.

“The whole purpose of Lean thinking is to identify and reduce waste.

We identified some waste in the processes between technicians and parts. We started with a problem and eliminated waste to minimize the problems.

The problems were as follows:

1. TECHS SPENT TOO MUCH TIME PICKING PARTS

“We had fixed size (36″W x 10″H x 12″D) fixed label tech pickup shelves at that time. The amount of parts the techs would pick up overflowed the shelf and the paperwork would get lost causing a great deal of lost time searching for the parts that belonged to certain jobs.

We assessed the situation and came up with a shelving system with magnetic movable labels and separators that allowed all of the parts for jobs to be on the shelves. We then made certain that parts did not get put on that shelf unless the parts to complete the job were all there.

We did not measure the productivity gain, but we can very safely assume that we saved each tech 5 minutes (it was definitely more) per parts replenishment visit.”

“Because the separators were movable this shelf quickly became a visual management tool.

We could quickly identify the techs that were overloaded with work as their shelf became bigger and more crowded with parts. When this happens, we can now assign the work to another tech to complete the repairs faster.”

2. WE CONSISTENTLY RAN OUT OF CERTAIN CHEMICALS

“At that time, chemicals were stored on the bottom of a rack in the parts department. It was difficult to stock and exercise first-in first-out rules. It was also difficult to identify anything that would be missing.

Some of these chemicals could not be tracked within the inventory system because techs would not use a full can. These products where billed in .25 can increments. Inventory in the system was never accurate.

So we moved all of the chemicals to their own location that can be accessed from all points. This allows us to see the chemicals that are running low and stock from the back and pull from the front to prevent aging inventory.

We have not run out of a chemical since we made the change.”

3. WE HAD DIFFICULTY MANAGING THE WAREHOUSE AND PUTTING AWAY STOCK

“It would take more time than we felt like it should to put away stock. Our shipping clerk is very familiar with the way he organized the shelves so he is efficient. When our shipping clerk is absent, we would have a difficult time managing the warehouse and putting away stock.

The entire shelf section was listed as one location in the system.

We now only have one shelf to search when pulling and stocking parts.”

This has allowed great flexibility and efficiency. It reduced pull times tremendously speaking from personal experience.

These process improvements have reduced the pain points.”

VISIBILITY, STANDARDIZATION, & VISUAL MANAGEMENT

Brady Muller | Service Process Manager & Lean Champion

“Applying 5S principles throughout our shop and parts department. It’s very visible when you walk through those areas of our facility, as you will see a lot of segregation, identification, and designation.

You will also see a lot of standardization in terms of how our shop is set up.

Every bay layout is set up the same/standardized as well as other areas of the shop. While we still have Kaizen opportunities, our team has made a lot of progress in these areas.

We’re using tools such as A3 forms to manage issues/projects, process workflow charts to document high level process flows, and we have developed our own standard work instruction document that’s in line/has the key elements (including “How”, “What”, and “Why”) that the Toyota factory uses.

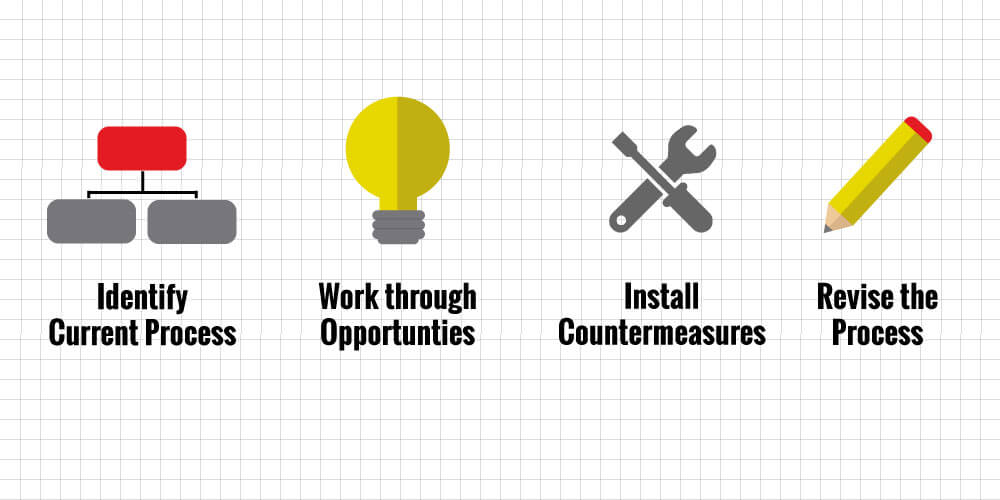

In addition, we’re taking a more strategic, lean approach to documenting processes. We start by identifying the current process through a process flow chart, then we work through the hang ups/opportunities within it, addressing each of those opportunities and installing countermeasures into our process, then revising the process.”

“Visual Management – this is something we’re just really getting into.

We’re currently working on installing monitors throughout our facility to display important KPI’s to our team.

But to really take advantage of visual management, we’re working on a couple of projects in both our field service and shop departments to help us manage our workload more efficiently. These are in the early stages, but something I feel will be beneficial to us once implemented.”

SMALL IMPROVEMENTS MAKE BIG DIFFERENCES

Kevin Sweet | Vice President of Operations & Lean Champion

We are using Toyota Lean Management in almost every area of our operation.

TLM has improved our customer experience from the time a customer walks in our doors. It’s a matter of having better documentation for procedures so they know that they will receive the same experience from us through any of our departments.

Most of the time it’s tough to get a customer to break away from their facility to visit us but if we are able to have them stop in and see our facility it really increases our chance of solidifying a deal.

We utilize an Andon Board in our shops and parts to track equipment and parts orders. The board used in our shop is literally touched by every person that works in our shops and allows us to identify the status and location of all equipment.”

“I think our takeaway from TLM is small improvements, just keep making small improvements (in any area that you see you can improve).

Before you know it these small improvements make big differences.

ONE STEP AT A TIME

Josh Smith | Corporate Administrative Manager & Lean Champion

“At Toyota Forklifts of Atlanta, we are applying Toyota Lean Management in several different ways.

We constantly think about how we can transform Toyota’s lean manufacturing activities into our service organization.

Our foundation began a decade ago when TMHU launched the ASEC Program. After our certification we purposed to sustain ASEC activities and make it part of our culture.

We then began to implement 5S principles for housekeeping, organization, and sustaining a clean environment.

Once our major 5S efforts were complete, and being sustained, we began developing standardized, repeatable work and processes.

All efforts rely heavily on our people bringing Kaizen opportunities across the organization.

Currently we are focusing on our next two steps, visual controls and Hoshin Kanri.

Visual Management is meant to show our current condition, identify the outcome and visualize the gap. Our associates develop actions to attack the gap.

Hoshin Kanri, known as shared corporate strategic planning, is developing and communicating the corporate goals, the departmental goals and the individual goals that, through actions support the realization of the corporate goals.

Applying lean management principles has literally opened the door for inviting customers to tour our lean facilities which deepens and strengthens our relationship to make customers for life.”

There you have it! Insight from Toyota experts on how they’re applying lean management principles.