For many businesses, forklifts are essential equipment for lifting and moving heavy loads.

They can weigh anywhere between 3,000 to 20,000 pounds, making transporting a forklift from one worksite to another quite challenging.

Proper handling during transport prevents accidents and injuries while preserving the machine’s condition and minimizing repair costs.

Since forklifts are not classified as automobiles, they require specific transport methods for public road travel as we will learn in this detailed guide.

Let’s dive in!

Understanding Forklift Transport

Forklift transport involves many ways to move forklifts from one location to another.

Forklift Transport Options

There are various options you can choose from when you need to transport forklifts, such as:

1. Tow Trailer

A tow trailer provides a fast and budget-friendly option for transporting forklifts. However, ensuring the trailer has sufficient weight capacity can withhold your lift. Once you have verified the trailer has enough weight capacity, drive the forklift onto the trailer and secure it firmly with straps or chains. This option is suitable for short to medium distances and is somewhat easy to arrange.

Also, before you set off, confirm that the lift is rigged and secured.

2. Tilt Tray Truck

At its core, a tilt tray truck excels in transporting forklifts, boasting the capacity to haul up to four forklifts, contingent upon their size and weight. These trucks feature a tilt tray bed, making them convenient for loading and unloading forklifts with ease.

3. Flatbed Truck

A flatbed truck provides adequate space and a substantial weight capacity to accommodate one or even multiple forklifts. They come equipped with a low deck, which ensures easy clearance when passing under bridges or through tunnels.

4. Automated Tailgate

An automated tailgate is not only the largest but also the safest way to transport forklifts. It enables the transportation of large quantities of forklifts due to its substantial weight capacity. Nevertheless, it is crucial to plan the route to avoid low bridges.

Before making a final decision about forklift transport, examine carefully these options. This consideration will enable you to identify appropriate transportation option. Plus, you can reduce the risk of delays when transporting these heavy machinery.

Warehouse managers often rely on forklifts as their trusted companions. Forklifts enable smooth and efficient movement of large and heavy objects within the distribution center or the warehouse. As powerful as they are, shipping them can be quite a headache.

Challenges of Shipping Forklifts

One of the primary challenges in shipping forklifts is the limited demand for specialized shipping services. This demand leads to an increase in the cost of transporting forklifts. Since flatbed carriers, which generally have higher rates, are predominantly used for shipping forklifts, the total expense can often surpass initial estimates.

As a result of the low demand for forklift shipping, carrier selection becomes a problem, as there are fewer dedicated carriers for this specific type of shipment.

For instance, the demand for auto shipping is very high. Due to this high demand, more vehicle carriers are available, which drives down prices and increases shipping availability. The lack of demand for forklift shipping leads to higher prices and lower availability.

Another challenge of shipping forklifts is loading and unloading them onto trucks or containers. Given their weight and dimensions, forklifts often need specialized equipment. Utilizing equipment such as ramps or cranes is essential for lifting and precise positioning of the vehicles.

Legal Axle Weight Limits

When shipping a forklift, consider factors such as legal axle weight limits. It is the maximum weight that a single axle or a group of axles on a vehicle can carry without exceeding the legal limit set by transportation authorities. These weight limits are in place to ensure the safety of the roads, bridges, and other infrastructure. They also help prevent excessive wear and tear on vehicles.

The shipping method is influenced by its size, forcing you to utilize specialized trailers such as dry vans.

The dry van boasts a weight capacity of approximately 45,000 lbs and can house freight up to roughly 9 feet, 2 inches in height. Should a forklift exceed this height limitation, there exist alternative transport methods. One can either detach the mast and forks of the forklift to fit within the van or opt for transportation on a flatbed trailer.

A standard flatbed height should be five feet high, allowing 8.5-9.5 feet of vertical space to transport a forklift with its forks in the downward position. In certain regions, this height may vary slightly.

When transporting taller forklifts, opting for a step-deck or a low-boy trailer is advisable as they offer increased vertical clearance.

However, depending on the height and regulatory requirements, you may need to obtain a permit for shipping taller forklifts.

Some heavy-duty forklifts, while adhering to legal weight restrictions, can exert a significantly higher pressure on the floors of trailers. This phenomenon largely stems from their design, which combines substantial mass with a compact footprint.

With such forklifts, the trailer floor must be sturdy enough to accommodate this weight without collapsing or sustaining damage.

Clearance Height Considerations

Throughout the entire route, awareness of the clearance height is essential. Clearance height refers to the available vertical space that allows the forklift, including its mast, to pass through without any obstacles.

Essentially, to ensure a smooth process while transporting forklifts, several clearance height considerations should be taken into account, including:

- Bridge and overpass clearances: Check the height restrictions of bridges, overpasses, and tunnels along the planned route. Make sure the forklift, including any raised attachments or masts, can clear these structures without causing any accidents or damage.

- Entrance and exit clearance: Determine the clearance height at entry and exit points, such as parking lots, warehouses, or other locations involved in the transportation route. Ensure that the forklift can navigate through these areas.

- Doorway and passage heights: Measure the height of doorways, narrow passages, or any other points the forklift needs to pass through. Compare these measurements with the height, including raised attachments, to confirm enough space exists.

- Loading and unloading areas: Consider the clearance height at loading docks, ramps, or any areas where the forklift will be loaded or unloaded. Verify that the height allows for a safe forklift transfer without any height constraints.

- Construction and road work: Be aware of ongoing construction or roadwork along the transportation route. Temporary structures or elevated platforms could affect the clearance height. Thus, stay updated on potential changes that might impact the passage.

Safety Precautions and Procedures

By prioritizing safety, you can identify potential hazards and decrease the risk of accidents or damage. Moving a forklift does not have to be overly complicated— all it requires is a careful approach and compliance with proper safety precautions.

Safety Precautions for Forklift Transport

Consider the following safety precautions when moving forklifts:

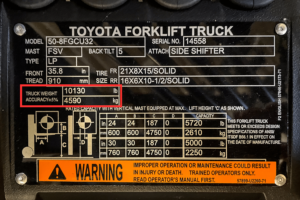

1. Weigh Your Forklift

Before transporting your forklift, determine its weight and ensure it is compatible with your trailer. Check the weight capacity of your trailer, as capacities can vary depending on the specifications.

Though it is not just about weight, consider the length of your forklift trailer to ascertain whether it can accommodate your specific forklift.

2. Inspect Your Forklift

Ensure your forklift is working before loading it onto the transport vehicle. Inspect the forklift and confirm that everything is in order. Remember to place wheel chocks to prevent any accidental rolling of the forklift.

If the trailer is not attached to a truck, employ a nose jack and position it beneath the front of the trailer. This action ensures stability and safeguards against any potential tipping or imbalance during the forklift loading process onto the trailer.

3. Center Your Forklift

Transporting a forklift in a trailer demands mindful attention to centering the machine properly. Start by lowering the forks onto the floor and tilting them forward. Place wooden blocks behind every wheel of the forklift to offer stability. Secure the blocks by driving screws into the wooden floor and the blocks of the transport vehicle.

4. Load Your Forklift

When loading your forklift onto the truck or trailer, drive it in reverse, ensuring the forks are facing away from the transport vehicle. This positioning helps to guarantee safer and more efficient loading and unloading. Be aware of the specific forklift transport policies recommended for your job site, as they may have additional requirements or guidelines to follow.

5. Switch off the Fuel Supply

Before departing, ensure to disconnect the propane tank. For those operating diesel- or gasoline-powered forklifts, verify that the fuel tank is tightly fastened to avoid potential fuel spills. Additionally, disconnecting the battery terminal is advisable to prevent electrical arcing. Ensuring the battery of an electric forklift is fully charged before setting off is crucial.

6. Utilize Chains and Come-Alongs

Chains and come-alongs help in fastening the forklift. Tighten them to the edges of the truck bed and ensure they are firmly secured. Create four anchor points at every corner of the truck, utilizing at least two chains or come-along for each anchor point.

Securing a Forklift for Travel

When using a dry van, firmly secure your forklift using the blocks and braces nailed to the trailer. It is worth noting that some dry van carriers may decline to transport forklifts due to the holes and nails left behind by this bracing.

Utilize straps and chains as an additional safeguard against any movement during transit. Utilizing padding beneath these constraints is recommended, as it acts as a safeguard, mitigating the risk of damage caused by friction on the forklift.

The process of loading a forklift onto a trailer generally presents minimal difficulty. In many instances, forklifts, like other self-propelled vehicles, can be maneuvered onto trailers using ramps or docking platforms.

Following placement on the vehicle, ensuring proper securement is critical—a task typically undertaken by specially trained personnel adept in brace-and-block techniques. In certain situations, drivers may assume responsibility for securing their load thoroughly—conducting inspections post-securement—to mitigate risks associated with property damage or injuries during transport.

Securing Forklift with Ratchets and Chains

Using ratchet and chains often results in a slower but more stable loading and unloading process. Their handles store less energy, making them safer to use as the risk of recoil is minimal.

Here is a step-by-step guide on how to secure a forklift with ratchets and chains:

- A) Position the forklift: Drive your forklift onto the flatbed truck, carefully positioning it in the desired location for transport.

- B) Identify anchor points: Locate suitable anchor points to attach the ratchets and chains. These anchor points should be capable of withstanding the weight and force exerted by the forklift during transportation.

- C) Attach the chains: Tighten the chains and ensure they are attached to a strong and stable point on the forklift frame. Avoid attaching chains to any moving parts or delicate components.

- D) Connect the ratchets: Attach ratchets securely to the chains and ensure they are fastened to the anchor points on the truck. The ratchets must be correctly attached to maintain a firm grip on the forklift.

- E) Check stability: Once the chains and ratchets are in place, assess the forklift’s stability. Look for any signs of movement or shifting. If necessary, adjust the tension of the chains and ratchets to achieve a firm and stable position.

- F) Conduct a safety inspection: Inspect the securements, including the chains, ratchets, and anchor points, to ensure everything is in place. Verify that all connections are tight and there are no indications of potential loosening or failure.

Safety Procedures During Transport

As discussed earlier, transporting forklifts requires keen attention to safety to protect both personnel and the transported equipment.

Adhering to safety procedures significantly reduces the risk of potential hazards.

First, tighten the forklift to the transport vehicle using chains, straps, or ratchets to prevent movement or shifting during shipping.

Maintain proper weight distribution on the transport vehicle to promote stability. Evenly distribute the weight of the forklift to minimize imbalances that could contribute to accidents or loss of control.

Comply with the regulations and guidelines specific to forklift transport. Compliance helps guarantee a safe and legal transport process.

Before transportation, conduct a thorough inspection of the forklift. Look out for any signs of leaks, components that may have become loose, or any mechanical irregularities. It is essential to verify that all critical systems—such as brakes, steering mechanisms, and lighting—are working.

If the forklift has detachable parts, secure or remove them before transportation. Loose or unsecured parts can cause accidents or fatalities during transit.

Choosing the Right Carrier and Equipment

When you are selecting a suitable carrier to ship your forklift, here is what you will need to check before settling on a carrier for your forklift shipment:

- Experience: Choose a carrier with experience in transporting heavy machinery and a track record of handling similar shipments, particularly forklifts.

- Equipment and resources: Check if the carrier has the right equipment and resources for forklift transportation They should have specialized trailers or flatbed trucks designed for hauling heavy machinery. Also, consider if they have the necessary loading and unloading equipment, such as ramps or cranes, to handle the forklift safely.

- Licensing and insurance: Verify that the carrier holds licenses and permits for transporting heavy machinery like forklifts. Find out if they have sufficient insurance coverage to protect your forklift in case of any damage or loss during transportation.

- Safety record: Look for carriers with a good safety track record and positive customer feedback. This information gives you confidence that they can handle your forklift shipment safely.

- Transit time and delivery options: Confirm the estimated transit time and the available delivery options. You may require expedited shipping or specific delivery arrangements. Discuss these requirements with the carrier to ensure they can meet your timeline and preferences.

- Cost and pricing: Obtain quotes from multiple carriers and compare pricing structures. Evaluate their value, accounting for factors such as reputation, equipment quality, and level of service.

Specialized Equipment

Specialized equipment and trailers depend on the nature of your forklift transportation needs. The following are the various types of specialized equipment you can use in forklift transport:

- Cranes and lifts: Cranes or lifts may be used to load or unload forklifts onto trailers and transport vehicles. These heavy-duty lifting devices can handle the weight and size of forklifts and are commonly employed when dealing with exceptionally heavy or oversized forklifts.

- Ramps and dock plates: This specialized equipment bridges the gap between the ground and the trailer or transport vehicle. They provide a smooth transition for forklifts moving from the ground onto the transport equipment.

- Straps and chains: Straps and chains tightly fasten the forklift to the trailer or transport vehicle, preventing movement during transportation.

In forklift transport, specialized trailers accommodate the unique dimensions and weight of forklifts, simplifying the loading and unloading process.

Specialized Trailers for Forklift Transport

These specialized trailers provide the necessary features and configurations to transport forklifts, minimizing the risk of damage.

1. Drop Deck Trailers

Also referred to as step deck trailers, drop deck trailers have a lower deck height at the front and a higher deck at the rear. This design allows forklift transportation without height restrictions, especially for taller forklift models.

2. Side Loader Trailers

Side loader trailers are specifically designed with a side-loading mechanism. These trailers enable forklifts to be loaded and unloaded from the side, enhancing convenience and safety during the transportation process.

3. Lowboy Trailer

Lowboy trailer has a low deck height, allowing forklifts to be loaded and transported with minimal ground clearance. They are useful when transporting larger or taller forklifts that may not fit on standard trailers.

Forklift Shipping Methods

The first step of loading a forklift onto a trailer is to check the weight of the forklift. Knowing the weight of the forklift enables you to choose the suitable securement method and select the proper straps needed to fasten the forklift effectively.

As soon as you have reviewed the weights, you will need to center the trailer so that both sides have equal distances from the trailer edge. After that, tilt the forks forward. Fix sturdy screws behind each wheel of the forklift to ensure that it stays immobile and stable.

Next, turn off the engine, cut off the fuel supply of the forklift, and disconnect the batteries. To ensure proper security, utilize chains and straps to fasten the forklift.

While shipping this heavy machinery, you will need reliable and specialized freight shipping companies that can handle the task efficiently. These companies have the expertise and resources to handle the unique requirements of forklift transport.

- FedEx Freight

- UPS Freight

- XPO Logistics

- Old Dominion Freight Line

If you need to relocate a forklift, it is essential to familiarize yourself with the available options for loading, shipping, and delivering.

The choice of forklift transportation hinges on your specific needs, the size of the forklift, and the availability of suitable transportation. To discover the best practices for successfully shipping your forklift, continue reading!

Know What Your Forklift Weighs

Forklifts come in various weights. While some forklifts may have a relatively modest weight of around 9,000 pounds, which still surpasses the weight of an average vehicle, there are also larger forklifts that can tip the scales at over 100,000 pounds.

The weight of your forklift determines the transportation method. For instance, certain roads impose restrictions to specific weight limits. To ensure compliance with these restrictions, you must carefully assess the combined weight of your trailer and forklift. Understanding the vehicle’s weight and the trailer’s mass is essential, alongside an awareness of the load restrictions prescribed by the roads you plan to navigate.

Be Aware of Your Forklift Dimensions

The size of a forklift can also impact how you transport it. For example, if you acquire a forklift with substantial height, it might pose challenges when fitting it onto a standard truck or trailer. On the other hand, smaller forklifts may be appropriate for placement within a shipping container, offering layers of protection during transit for your machine.

Obtain the Right Truck to Ship the Forklift

Once you have measured your forklift’s weight and size, it is time to select an appropriate transport vehicle. Opting for a shipping container could be a viable choice for smaller forklifts. However, if you have a tall or heavy machine, you may need to locate a specialized trailer that can accommodate its unique requirements. You may need to consider using a flatbed. Whatever vehicle you decide on, ensure that it is well-suited for the needs of your machine.

Fasten the forklift appropriately

Securing and stabilizing your forklift for transport is essential for a smooth relocation. Ensuring the stability of heavy forklifts is essential to avoid unintended shifting or loosening.

To accomplish this effectively, consider implementing the following recommendations to properly secure your forklift:

- Ensure all tires are chocked.

- Around the forklift, set up four anchor points.

- Attach chains to the trailer bed to secure the forklift.

- Before transporting the forklift, turn off or disconnect the fuel supply.

Best Practices and Considerations

Adhering to specific practices and considerations while transporting forklifts can significantly reduce the risk of accidents and damage. Below are some best practices and considerations you will need to implement:

- Secure the forklift: Properly secure the forklift to the vehicle or container using suitable restraints such as chains, straps, or blocking. Confirm that the forklift is stable and will not shift during transit.

- Balance the load: Distribute the weight of the forklift evenly on the transport vehicle to maintain proper balance and stability. This helps prevent tipping and ensures safe handling during transportation.

- Clear visibility: Ensure clear visibility during transportation by removing any obstructive attachments or accessories from the forklift. This prevents potential damage and allows the driver to have a clear view of the surroundings.

- Protect sensitive components: Use protective measures like covering delicate parts or wrapping the forklift in shrink wrap to safeguard it from potential damage caused by external factors, such as debris, dust, or adverse weather conditions.

- Follow traffic rules: When moving a forklift on public roads, it is crucial to follow all traffic rules carefully. Observe speed limits, use proper signals for turns and lane changes, and keep a safe distance from other vehicles.

Review these Considerations

Transporting forklifts encompasses several considerations. One of the primary considerations is having a clear understanding of the size and weight of the forklift you intend to transport. This helps determine the appropriate transport vehicle to use and ensures adherence to weight restrictions on roads and bridges.

Once you have determined the size and weight of the forklift, decide on the most suitable transportation method. There are various options to consider such as using a flatbed truck, a specialized trailer, a shipping container, or even air freight for long-distance or international transport.

After determining the size and weight of the forklift, secure the forklift properly to avoid any potential shifting, tipping, or damage. Use the right restraints like chains, straps, or blocks to make sure they’re tightly fastened. This ensures the forklift remains stable and protected throughout the journey.

Plan and execute the loading and unloading process for a smooth and safe transfer of the forklift onto and off the transport vehicle. This may involve using ramps, loading docks, or other necessary equipment.

Moreover, consider route planning to select the most efficient and suitable route for transporting the forklift. Factors such as road conditions, weight restrictions, height clearances, and any required permits or escorts for oversized loads should be considered.

Conclusion

Forklifts are crucial for handling heavy loads in warehouses and industrial areas, with weights ranging from 3,000 to 20,000 pounds. Their significant weight makes transportation challenging as they cannot be driven like regular vehicles. Even minor mistakes during their transport can lead to accidents or fatalities, emphasizing the need for careful transportation methods tailored to each forklift’s size and weight. By prioritizing safety protocols, you can identify potential hazards and decrease the risk of accidents or damage during forklift transportation.