Welcome to our comprehensive guide on propane forklift fuel system troubleshooting.

If your propane forklift won’t start, you’ve come to the right place!

In this article, we’ll walk you through the most common fuel system issues that lead to a no-start condition and provide you with a clear, step-by-step process for resolving them.

Let’s dive in!

WARNING: Forklift Repair Can Be Dangerous Work. Always Put Safety First.

Only trained, qualified, and authorized individuals should perform maintenance on propane fuel systems.

Propane can be as cold as -44° F and will cause serious injury if it comes in contact with your skin.

Additionally, propane can leak from the fuel system and accumulate on the floor, presenting a fire or explosion hazard.

Always put safety first and call a professional before attempting to do any work yourself.

That said, if you’re not a trained technician, we’ll list the actions you can safely perform in the “Action Items” list after each section.

How Does a Propane Forklift Fuel System Work?

There’s a lot of confusion about how exactly a forklift propane fuel system works.

Let’s get on the same page by going through just that.

The Propane Fuel Tank

First off, it all starts with the propane fuel tank.

Liquid propane boils and turns into a vapor at -44° F.

So to keep it in liquid form, it needs to be cooled or compressed.

And that’s exactly what happens in the propane tank.

Additionally, the propane tank acts as a fuel pump.

The pressure inside the tank forces the fuel through the fuel line and into the next stop: The regulator.

The Regulator

From the tank, liquid propane flows into the forklift’s fuel regulator, first reaching the fuel filter.

There, it’s stripped of any contaminants.

After that, the fuel goes into the regulator.

But it can’t just be allowed to flow freely – it needs a “gatekeeper.”

And that’s the job of the fuel solenoid.

The fuel solenoid is opened only when the key is turned in the ignition and the starter is engaged.

At that point, the engine’s electronic control unit (ECU) supplies current to the fuel solenoid.

Then, the solenoid allows the liquid fuel to enter the regulator.

Once inside the regulator, two things happen:

- The liquid fuel decompresses and turns into a vapor

- The vaporized propane’s pressure is adjusted to between 3.5 and 5 PSI (in the case of Toyota’s). This is necessary since the fuel injector requires a precise pressure for combustion to take place

The Mixer

From the regulator, the vapor propane travels into the mixer.

That’s the component that mixes air from the air intake with fuel.

The Throttle Body

Once mixed, the air/fuel mixture goes into the electronic throttle body.

And that controls the amount of air/fuel that makes it into the fuel injector.

The Fuel Injector

After that, the mixture flows to the injector.

Inside the injector, the ECU adjusts the fuel flow and air/fuel ratio based on inputs it receives from sensors.

The Engine

The fuel injector then passes the air/fuel mixture into the engine’s intake manifold.

Once that happens, a spark from the spark plug ignites the fuel, pushes the pistons down, and drives the crankshaft.

The crankshaft transmits power through the transmission and to the wheels.

And that’s ultimately what allows the forklift to move.

Additionally, the hydraulic pump is driven by the engine, allowing the mast to lift and tilt, as well as powering any attachments.

Propane Forklift Won’t Start? Here are the Most Likely Fuel System-Related Causes

Now that you know how a propane forklift fuel system works, it’ll be easier to understand what can go wrong.

Here are some of the likely fuel system-related root causes of a no-start situation:

- Low fuel

- Fuel valve turned to the “off” position

- Improperly-fitted fuel coupler

- Clogged air filter

- Clogged fuel filter

- Bad fuel solenoid

- Leaking fuel regulator

- Frozen regulator

We’ll cover these issues in more detail in the next section.

How Do You Troubleshoot a Propane Forklift?

Every manufacturer makes a different propane fuel system for their forklifts.

So when troubleshooting fuel system issues, the process will vary depending on the manufacturer, the year of manufacture, and the forklift model.

For that reason, we’ll stick to Toyota propane forklift troubleshooting in this article, focusing on the Toyota 8-Series fork trucks with 4Y engines built prior to 2020.

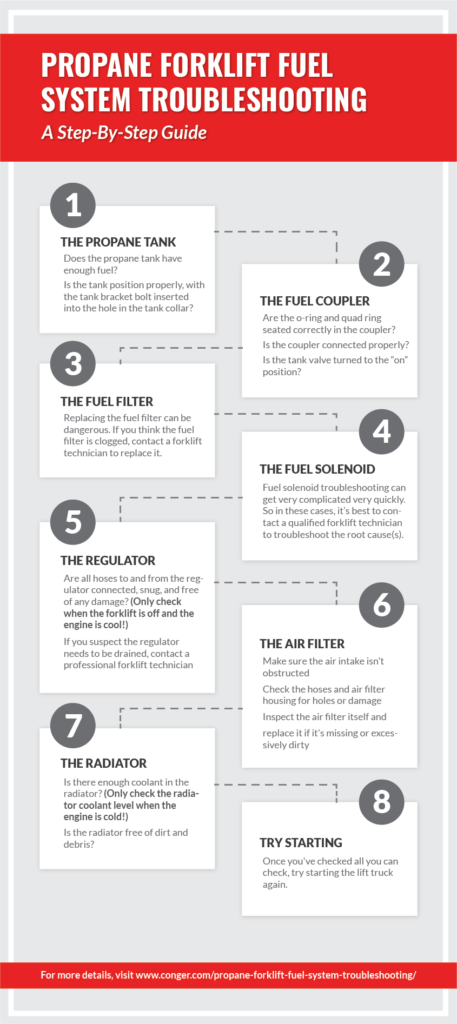

The Propane Tank

As you now know, everything in the fuel system starts with the propane tank.

So, when encountering a forklift that will not start, the troubleshooting process should start with the tank.

Often, you can find a simple tank-related problem that is preventing the lift truck from starting.

Is There Fuel?

So the first question to ask is: Is the tank full of fuel?

Most tanks have a gauge mounted on the top.

But these gauges have a reputation for being inaccurate.

So the better way to check the fuel level is simply by lifting the tank and feeling the weight.

A steel propane tank weighs around 36 lbs. when empty and 69.5 lbs. when full.

An aluminum propane tank weighs around 23 lbs. when empty and 56.5 lbs. when full.

So if the tank feels unusually light, then it’s likely empty.

In that case, go ahead and swap out the tank with a full one.

Is the Tank Installed Properly?

The next step is to check how the tank is mounted on the forklift.

When you buy a propane tank, it can be either liquid or vapor.

Forklifts with a radiator will use liquid propane, while air-cooled forklifts will use vapor.

But most lift trucks use liquid fuel.

So we’ll focus on that fuel source for this section.

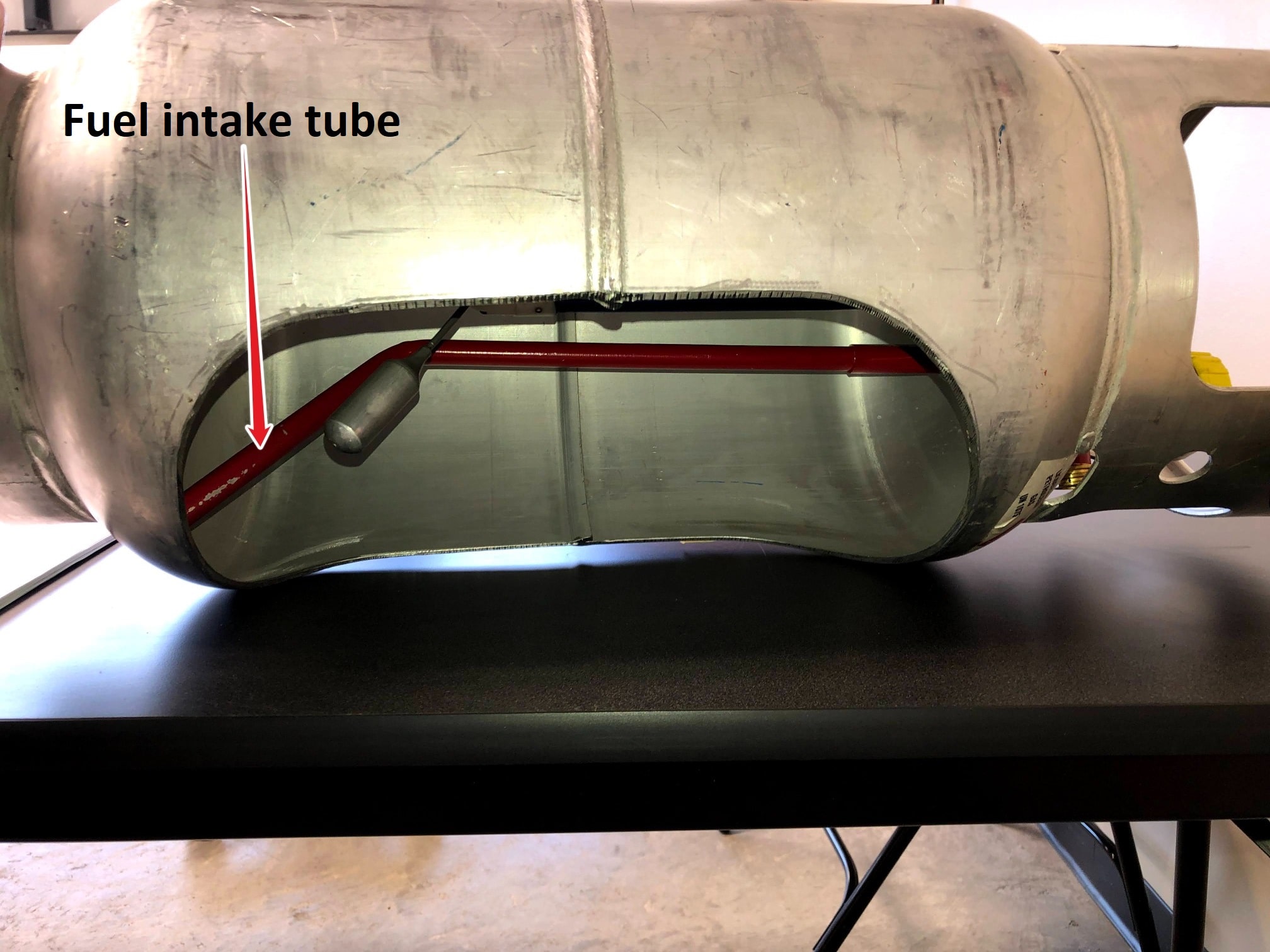

With a liquid propane tank, the pin in the tank bracket must line up with the hole in the tank collar.

That’s because the liquid propane has to get sucked up by the fuel intake tube inside the tank.

And that tube must always be on the bottom of the tank to draw the fuel.

But if the tank is placed upside down, the intake tube cannot draw the fuel and the forklift likely won’t start.

It’s like turning a sealed drinking cup upside down and trying to drink it through a straw – you’ll just be gulping air!

So you’ll need to make sure the tank is positioned correctly, with the forklift’s mounting bracket pin inserted in the tank’s collar.

Action Items:

- Does the propane tank have enough fuel?

- Is the tank position properly, with the tank bracket bolt inserted into the hole in the tank collar?

Once you’ve checked the fuel level and the tank installation, it’s time to move on to the coupler.

How to Start an LPG Forklift in Cold Weather

Cold weather presents some problems for propane-powered forklifts.

As we’ve noted, liquid propane is kept under pressure in the propane tank to maintain its liquid state.

The problem is that the colder it is outside, the more the tank will lose pressure.

And proper pressure is essential for the propane tank to do its job: Acting as a fuel pump to force the fuel into the rest fuel system.

So when there’s too low of pressure, the fuel cannot move as easily into the fuel system, and the truck will be harder to start.

Additionally, cold temperatures can cause the regulator itself to freeze, which further prevents the fuel from flowing and ultimately the forklift from starting.

So the key with a no-start situation in cold weather is getting the fuel tank and the forklift warmed up.

If you do that, chances are it’ll start right up.

The Fuel Coupler

Is the Tank Coupler Connected Properly?

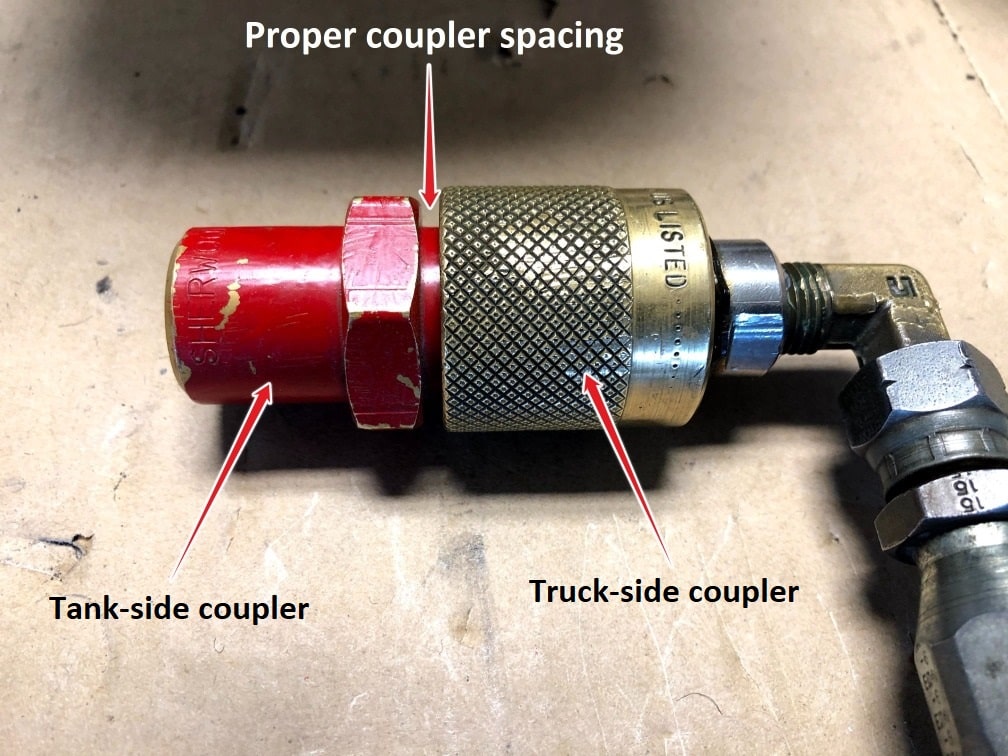

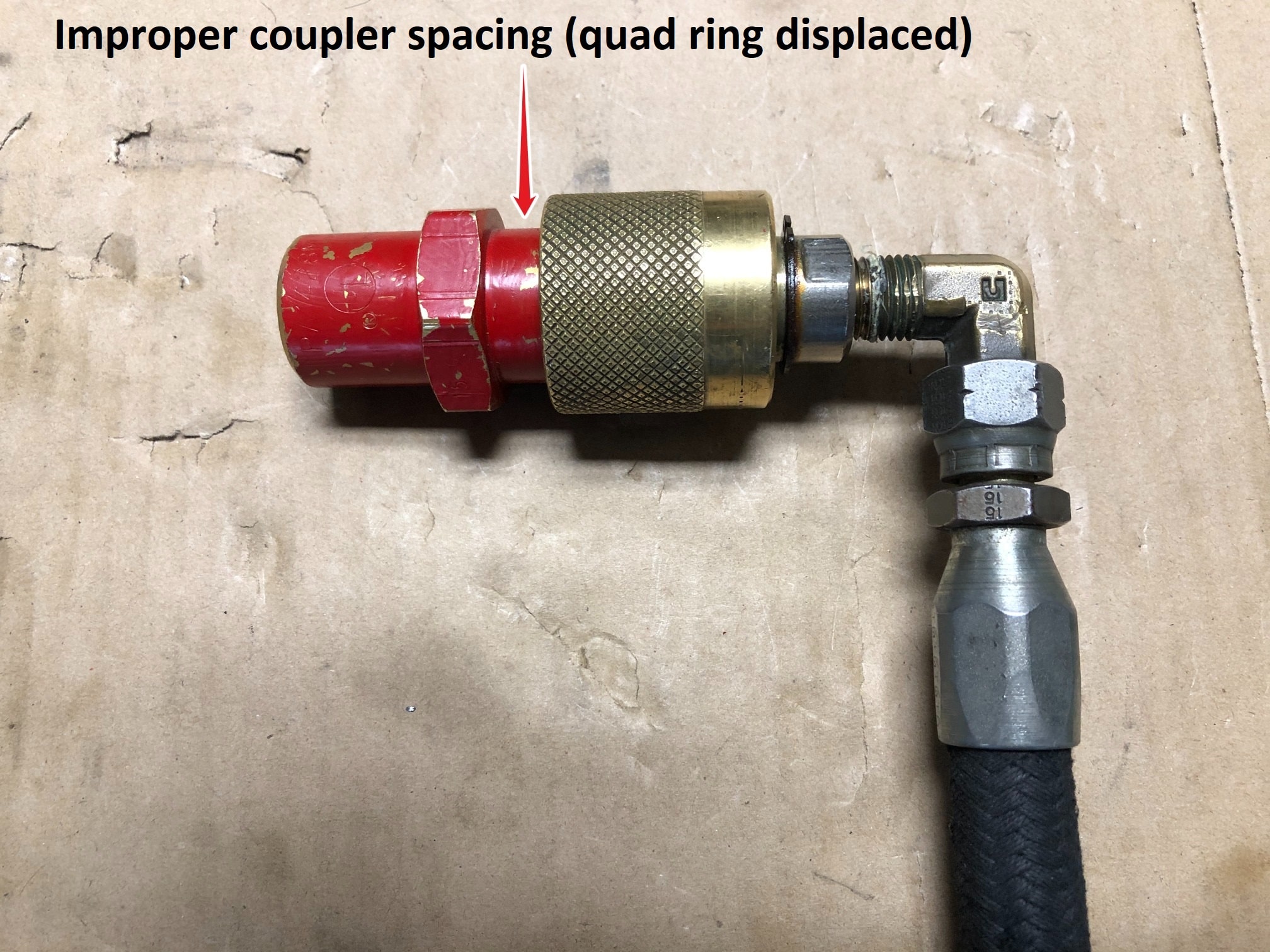

A common issue we see with forklifts that won’t start are improperly installed fuel couplers.

These are the components that connect the fuel tank to the forklift’s fuel line.

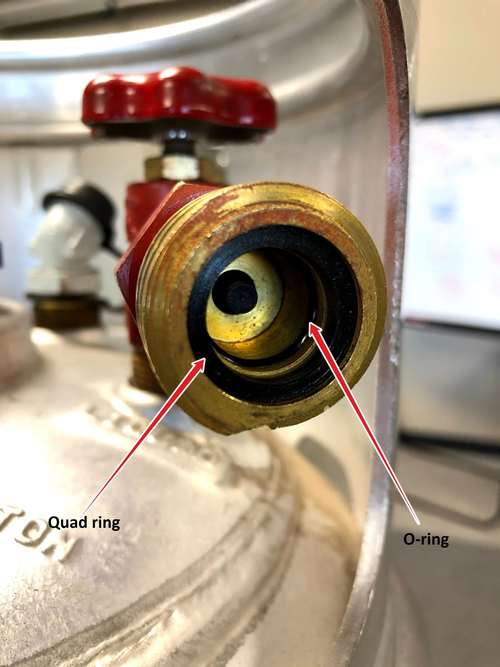

Inside the tank-side coupler, there are two rubber components.

One is an o-ring and another is a quad ring.

What happens sometimes is that the quad ring can pop out of place.

It’s easy to tell when that happens just by looking at the space between the couplers when they’re connected.

You want to see a small space between each.

But if you see a much larger space, that’s an indication that the quad ring has popped out.

And if that happens, several things won’t happen:

- There won’t be a proper seal

- The forklift-side coupler pin won’t engage with the tank-side valve

- The fuel won’t be released properly

- And your forklift won’t start

Fortunately, reseating these rings is easy.

Simply press the rings with your fingers back into place on the tank-side coupler and reconnect both couplers.

Additionally, it’s a good idea to keep a supply of these rings near where you store your tanks.

That way, you can quickly and easily replace them and save yourself a lot of hassle.

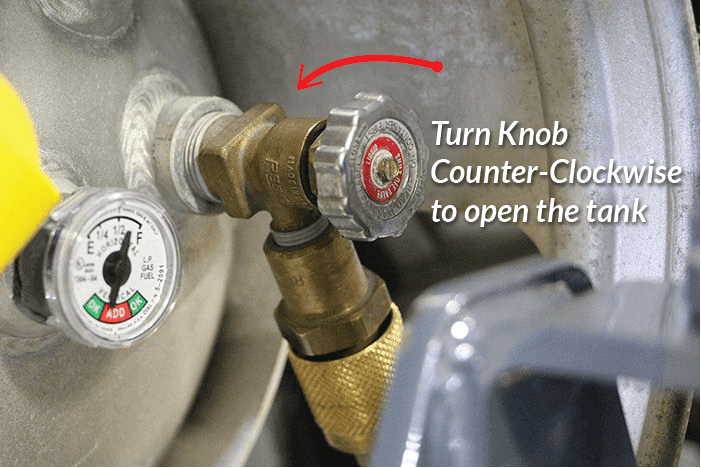

Is the Valve Turned On?

Once you’ve done that, the next step is to ensure the tank valve is turned to the “on” position.

Turning clockwise will close the valve, stopping the fuel flowage from the tank.

Turning counterclockwise will open the tank.

Action Items:

- Are the o-ring and quad ring seated correctly in the tank-side coupler?

- Are the couplers connected properly?

- Is the tank valve turned to the “on” position?

Now that we have the basics covered, let’s go over some important information about propane itself that you should know.

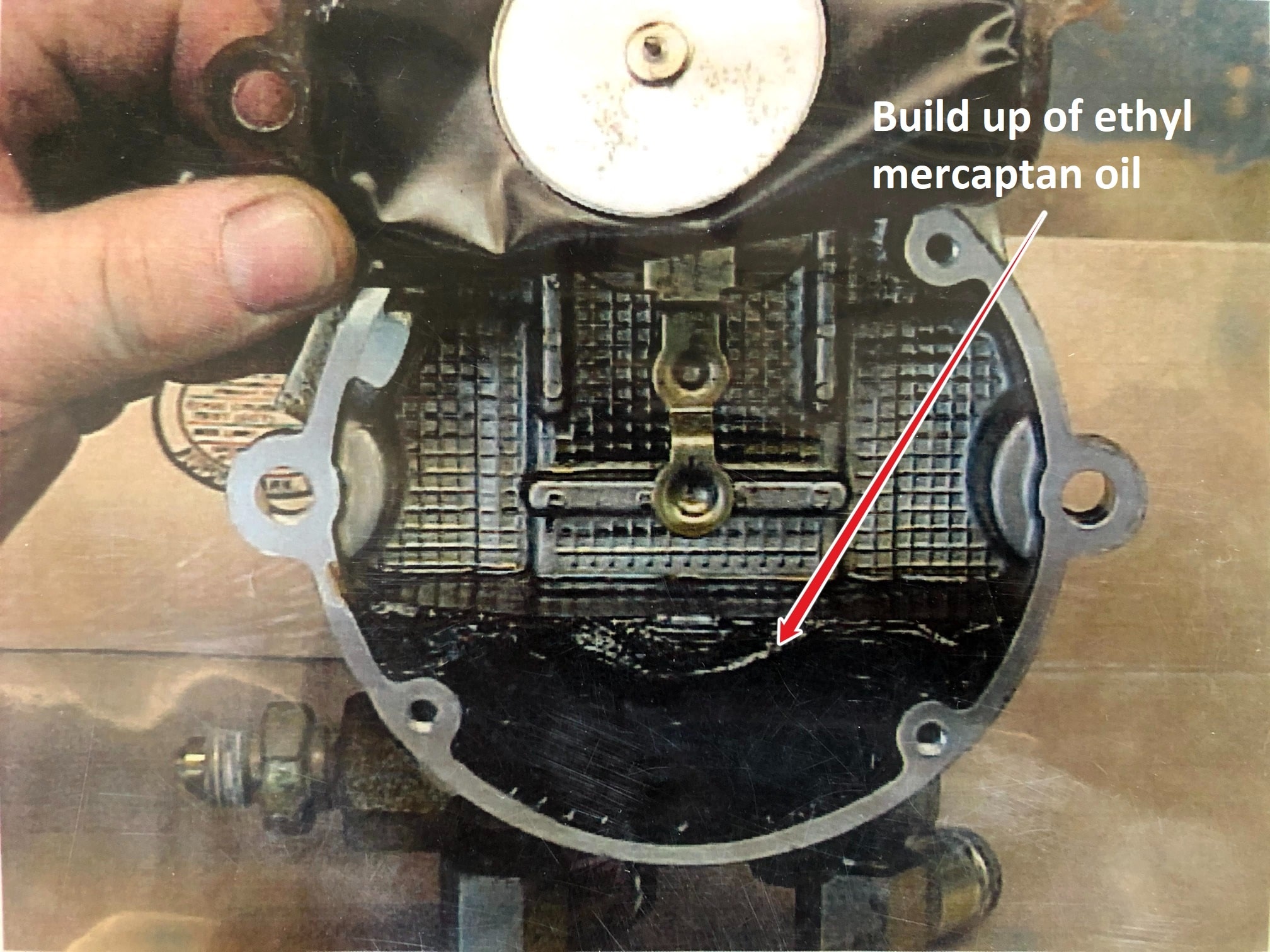

Ethyl Mercaptan: The “Secret” Culprit of Many Propane Fuel System Problems

Propane as a fuel source for lift trucks has a well-deserved reputation as a clean-burning, efficient energy source.

That said, propane itself is often full of dirt and other contaminants.

Those contaminants can be rust from inside of steel tanks, powder from the aluminum tank manufacturing process, paint chips, or any number of other particles.

Additionally, there’s another substance that’s added to propane during production: Ethyl mercaptan.

This is an oily substance used to give the normally odorless propane fuel it’s distinctive “rotten egg” smell for detection.

Normally, this substance will travel with the fuel and end up in the combustion chamber, where it will simply burn up.

But if the fuel isn’t at the proper temperature when it reaches the regulator, the mercaptan oil can separate.

We call this “cracking out.”

And when it happens, the oil can accumulate anywhere in the fuel system, including the regulator, the throttle body, the mixer, and the injector.

The result is that these components can become clogged and can result in a no-start situation.

It’s important to be aware of the existence of this oil and the problems it can cause.

Understanding that will help make the rest of the propane fuel system troubleshooting process easier to understand.

The Fuel Filter

Now that you’re aware of some of the issues with propane fuel itself, it’ll be easier to understand the role and importance of the fuel filter in a propane fuel system.

Sending dirty fuel into the engine is not a good thing.

So it must be cleaned first.

And that’s done through a fuel filter, which is mounted on the forklift’s regulator.

The fuel filter is a simple tube made of brass, copper, stone, or composite material that attracts contaminants from the liquid fuel that passes through it.

The problem is that over time, those contaminants can clog the fuel filter.

In that sense, it’s just like a coffee filter: At some point, the filter must be changed.

Otherwise, the flow of fuel will be inhibited and the forklift won’t start.

At a minimum, propane fuel filters should be changed every 2,000 hours.

Changing your forklift’s fuel filter is one of the most important maintenance items for fuel system integrity.

If you find that you’re replacing fuel filters often, that’s a good sign you have issues with dirty fuel tanks.

Consider swapping out your tanks for new ones and see if the problem persists.

But if your propane tanks are especially rusty, or the forklift is under high-use, it should be done more often.

Action Item:

- If you suspect that your fuel filter needs to be replaced, it’s best to call a qualified forklift technician. Because a forklift’s fuel line may contain pressurized liquid propane, changing the fuel filter can result in a release of that fuel. And if that happens, serious injury can result.

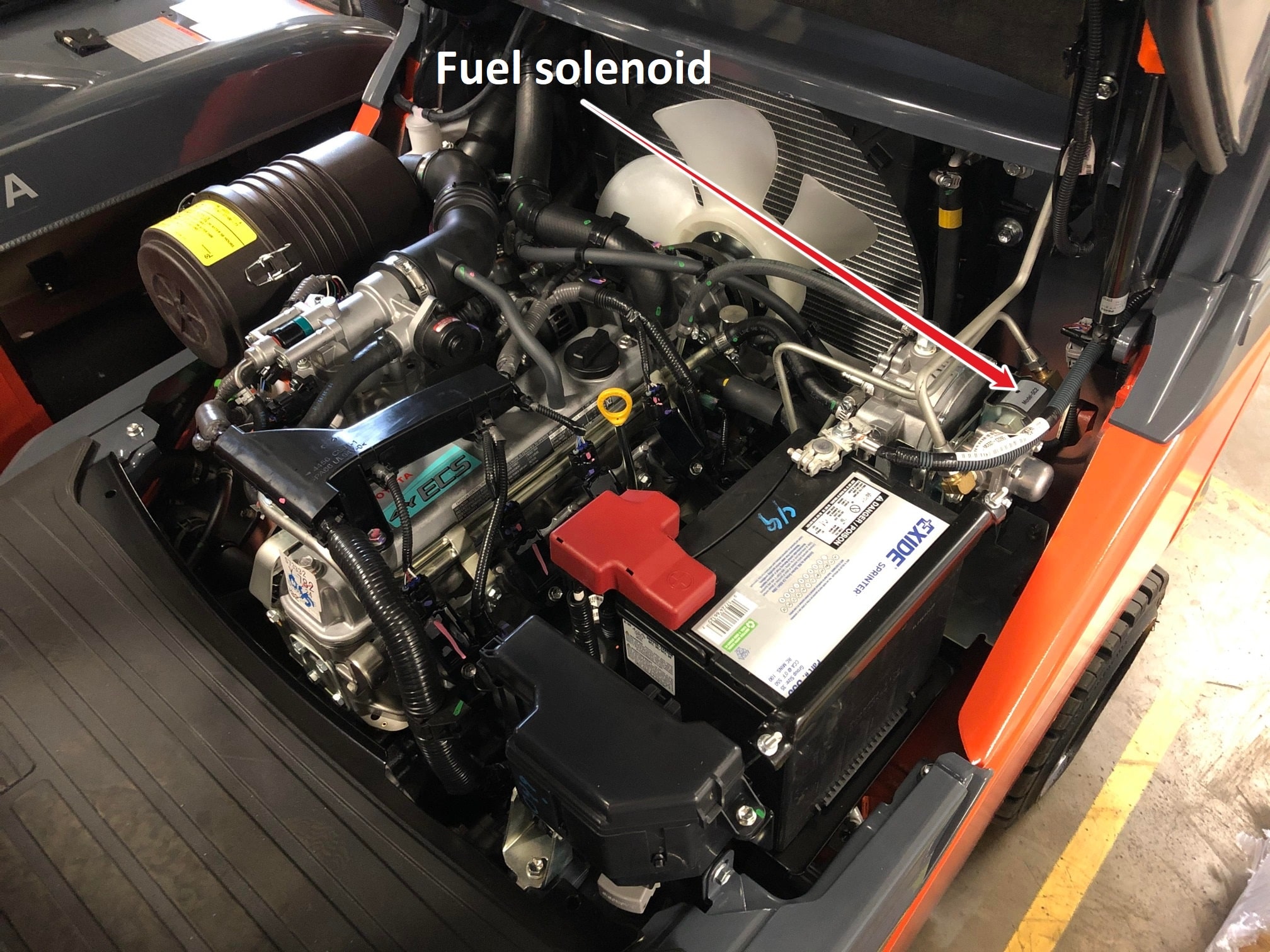

The Fuel Solenoid

As we noted in the How Does a Propane Forklift Fuel System Work? section, the fuel solenoid acts as a “gatekeeper,” preventing or allowing fuel to flow from the fuel line into the regulator and beyond.

If there’s an issue with the solenoid, the fuel will not be able to flow and the forklift won’t start.

Some common reasons that a fuel solenoid won’t work include:

- Broken wires

- Debris from a plugged fuel filter

- Bad sensor or code from the ECU

- Bad fuel solenoid

Action Item:

- Fuel solenoid troubleshooting can get very complicated very quickly. So in these cases, it’s best to contact a qualified forklift technician to troubleshoot the root cause(s).

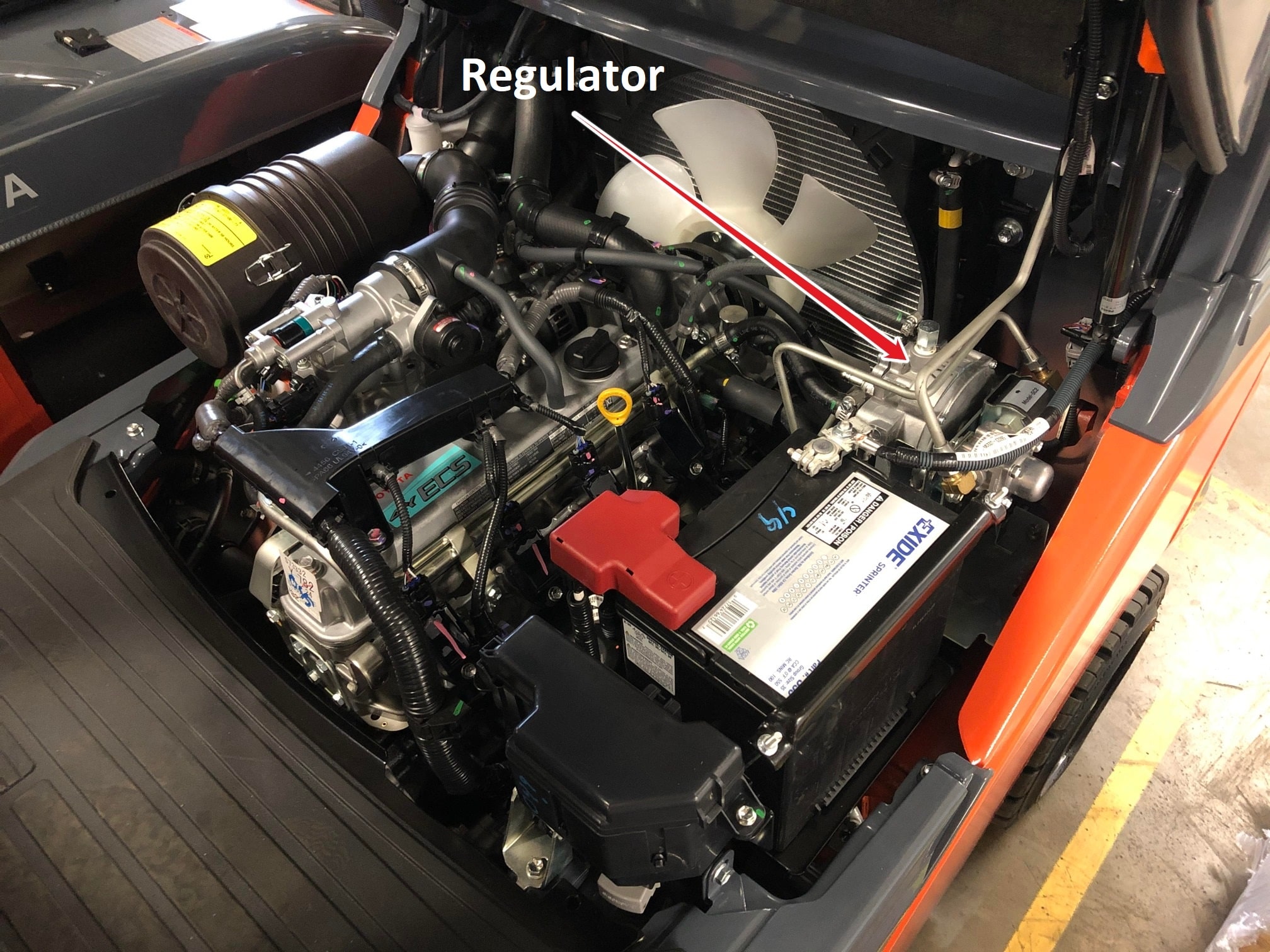

The Regulator

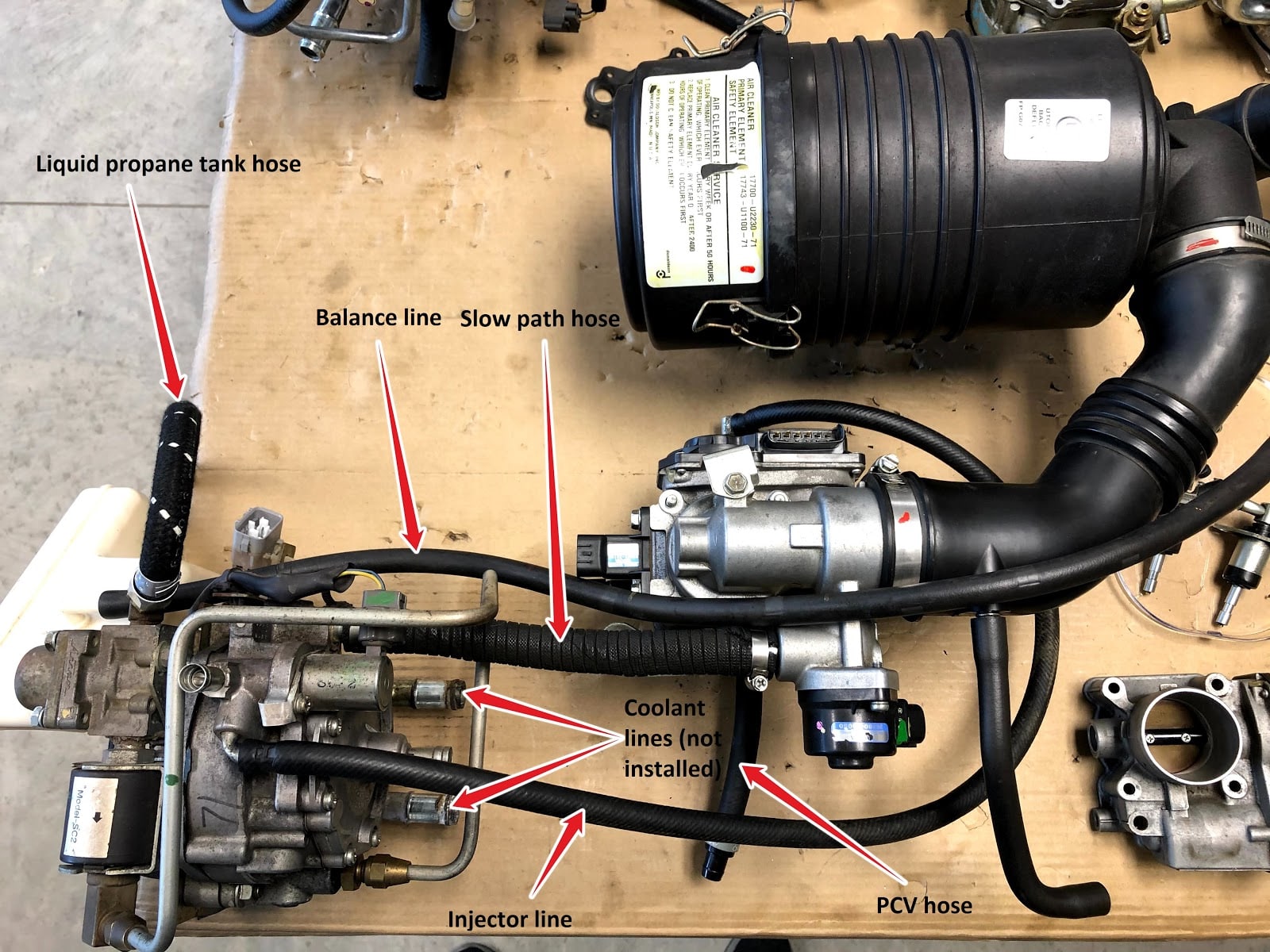

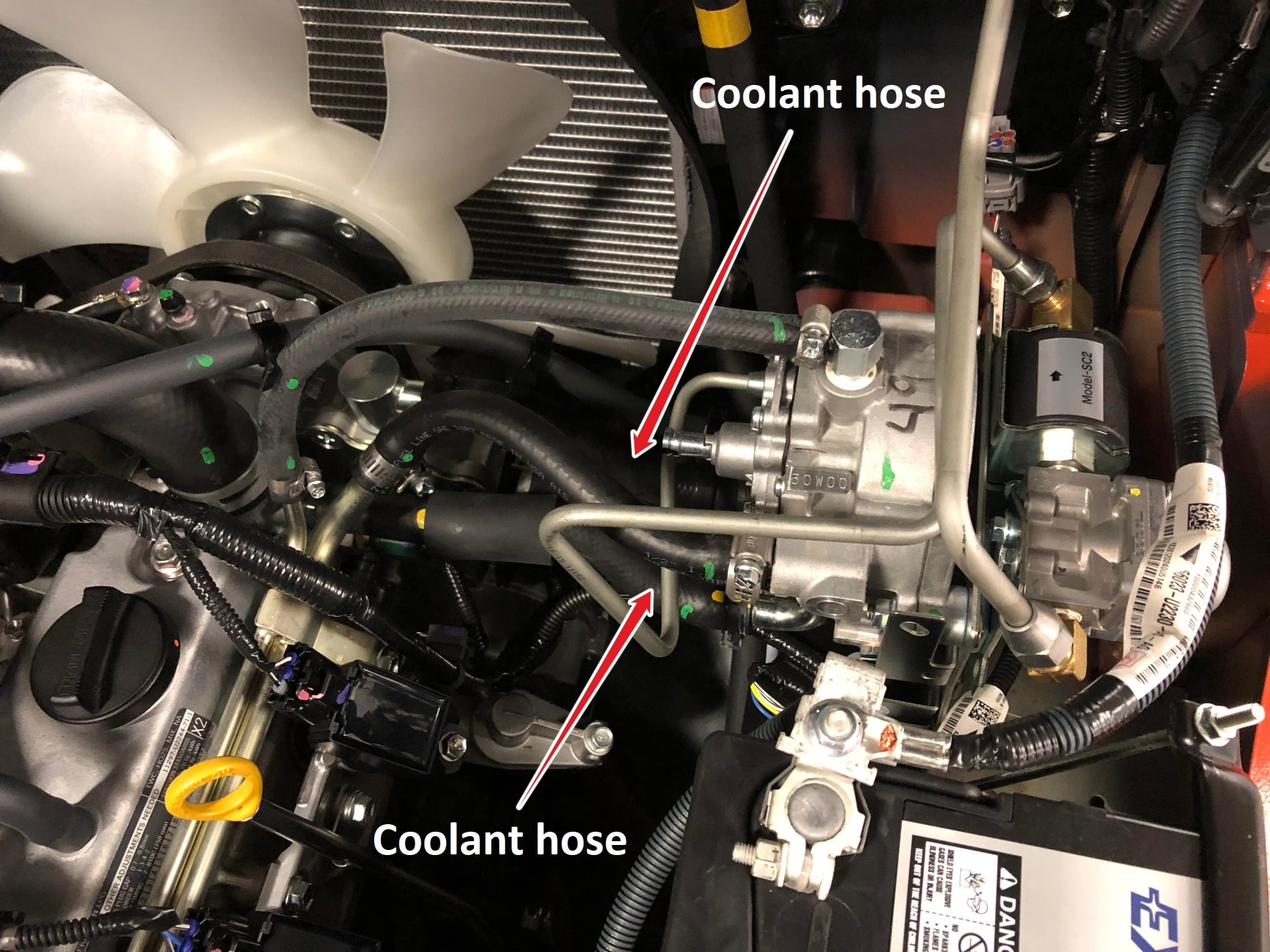

Are All Hoses Secure and Damage-Free?

If you’re experiencing a no-start situation with your forklift, and you’ve traced it to the regulator, you should first check the various hoses and tubes going to and from the regulator.

After all, propane fuel systems are very sensitive.

And something as simple as a loose hose can disrupt their function.

In a forklift regulator, you’ll find several hoses:

- Slow path hose

- Balance line

- Injector line

- Vacuum line

- PCV hose

- Coolant lines (in and out)

You can reference the image below for the location of each hose:

Check that these hoses are free of any damage or wear.

Then, check that they’re connected properly and snug.

Identifying hoses that are loose or need to be replaced is an easy way to solve no-start problems originating from the regulator.

Is the Regulator Clogged?

Remember the ethyl mercaptan we discussed just a few sections ago?

One of the top fuel system problems that’ll prevent a forklift from starting is when this oily substance gums up the regulator.

So when it comes to forklift propane regulator troubleshooting, the key is often eliminating the accumulation of that oil.

When the oil builds up, it will prevent the regulator diaphragm from moving properly.

Additionally, the oil can “pan fry” the diaphragm, which can cause it to fail.

And when the diaphragm is damaged or otherwise interfered with, the correct fuel pressure cannot be maintained and the forklift won’t start.

So what’s the solution?

Draining the regulator.

This involves:

- Opening a valve on the bottom of the low pressure side of the regulator

- Warming the forklift up

- Allowing the oil to liquefy and evacuate the regulator chamber

This needs to be done regularly – and more often if the truck is used heavily.

REMINDER: Regulator maintenance should only be performed by a qualified forklift technician. Propane is extremely cold and can quickly cause serious injury if proper precautions aren’t taken.

Should You Rebuild Your Regulator?

In years past, it was common to buy a regulator repair kit and rebuild the regulator instead of buying a new one.

But nowadays, it’s more common to simply swap out the regulator for a brand new one.

Why the change?

Well, it’s true that a regulator repair kit might cost half as much as a brand new regulator assembly.

But between disassembling, reassembling, and testing, it ends up costing more in labor to rebuild the regulator than to simply swap it out.

The good news is that with proper maintenance, regulators on a Toyota can last 10,000 hours.

But without it, the regulator will likely fail much before 10,000 hours.

Action Items:

- Are all hoses to and from the regulator connected, snug, and free of any damage? (Only check when the forklift is off and the engine is cool. And make sure to follow all safety warnings and decals!)

- If you suspect the regulator needs to be drained, contact a professional forklift technician

Propane Carburetor Troubleshooting

If your forklift was manufactured after 1999, it’ll have a mixer.

But if it was made prior to 1999, it’ll have a carburetor.

As with regulator troubleshooting, propane carburetor troubleshooting is often a matter of how filled with “gunk” it is.

After all, ethyl mercaptan can bypass the regulator and end up in the carburetor, causing it to malfunction.

So the key is to regularly drain the regulator so less of that oil ends up in the carburetor.

And that will reduce the likelihood of the carburetor failing.

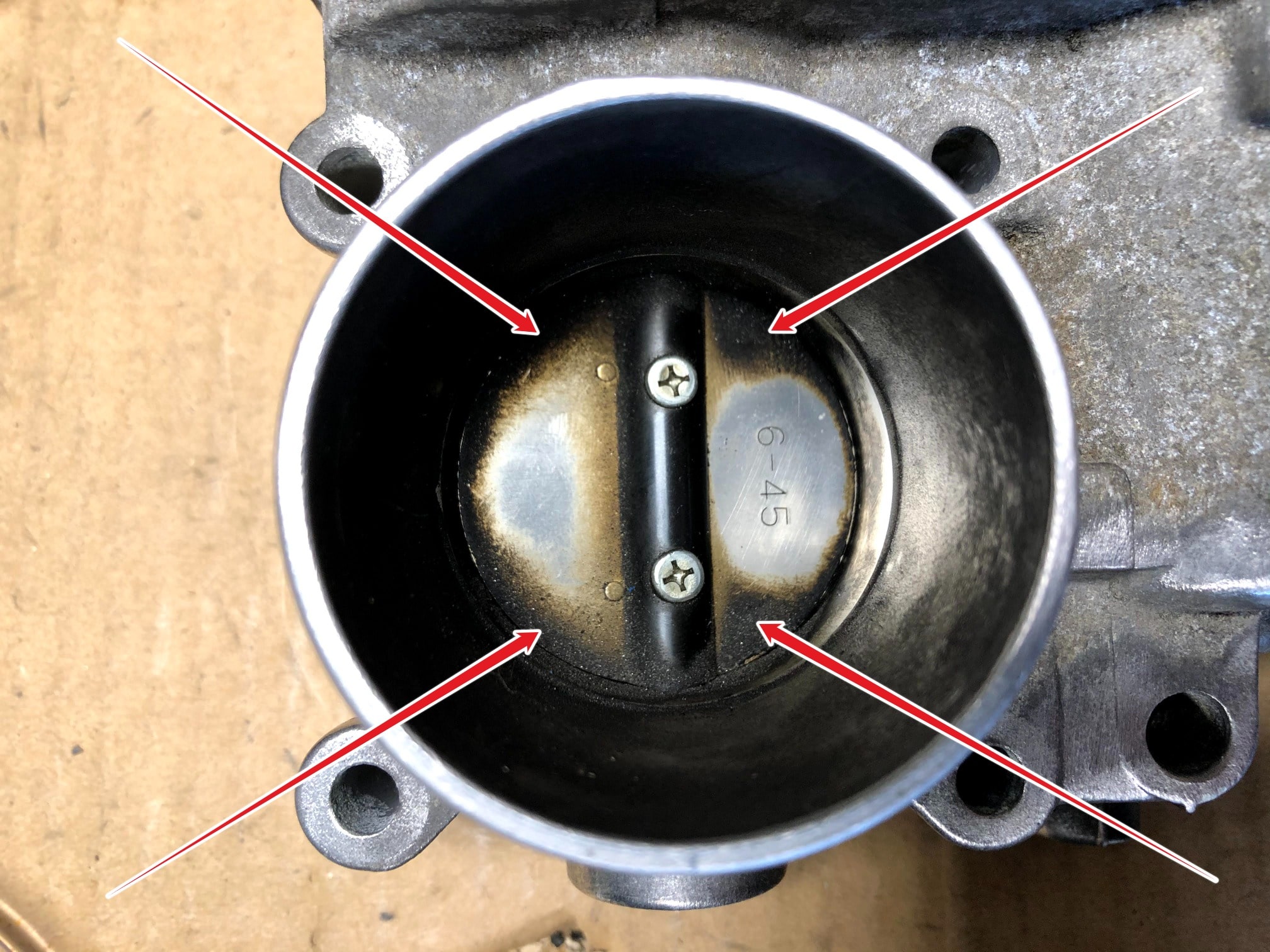

The Air Filter

In addition to fuel, engines require air for combustion.

So anything that interferes with proper airflow can cause the forklift not to start.

On a Toyota forklift, the air intake is located on the rear right-hand side pillar of the overhead guard.

Air is drawn through this vent, through a series of hoses, and then through the air filter.

Like a fuel filter, the air filter cleans the air and removes any contaminants that might mix with the fuel and interfere with the combustion cycle.

In this system, we often see three problems:

- The air intake is obstructed

- The air filter is excessively dirty

- The air filter is missing

And in any of those cases, the result can be that the lift truck won’t start.

So, if that’s the case, it’s a good idea to inspect the air system for any issues.

Then, try starting the fork truck again.

Action Items:

- Make sure the air intake isn’t obstructed

- Check the hoses and air filter housing for holes or damage

- Inspect the air filter itself and replace it if it’s missing or excessively dirt

The Radiator

Many folks don’t realize how important it is to maintain their lift truck’s radiator to prevent fuel system issues.

The reason is that the regulator depends on the coolant from the radiator to prevent it from freezing as super-cooled liquid propane flows through it.

So if the radiator and rest of the cooling system isn’t maintained, the radiator can literally turn into a block of ice.

And if that happens, fuel won’t flow and you’ll have a no-start situation.

So the overall key is to keep the coolant system in the truck running at the proper temperature, and filled with an adequate amount of coolant.

If you do so, you can do a lot to expand the longevity of your forklift’s fuel system components.

Action Items:

- Is there enough coolant in the radiator? (Only check the radiator coolant level when the engine is cold!)

- Is the radiator free of dirt and debris?

There’s a lot that can go wrong with a forklift propane fuel system.

That’s why proper and regular forklift maintenance is absolutely key to making your forklift function well and last a long time.

If you’re having trouble maintaining your forklift or your fleet, it’s best to reach out to an authorized service center for help.

Conclusion

There you have it: the complete step-by-step guide to troubleshooting a Toyota propane forklift’s fuel system.