This article is all about forklift weight capacity.

In it, you’ll learn:

- How forklifts work

- The difference between a forklift’s rated capacity and its actual capacity

- OSHA’s rules on forklift capacity

- How to calculate your forklift’s actual capacity

- And much more!

Let’s dive in!

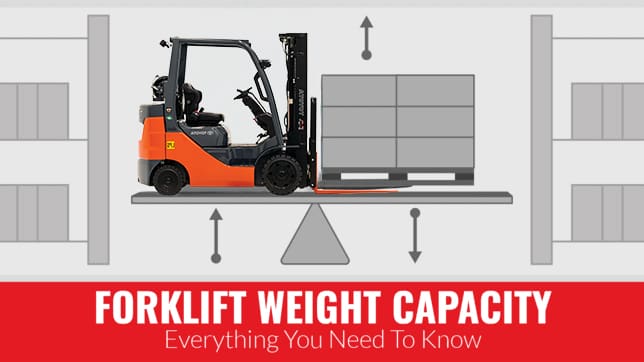

How a Forklift Works: A Balancing Act

Understanding forklift capacities first requires understanding how a forklift works.

In essence, a forklift is like a seesaw.

That is, the weight on one side of the seesaw must be balanced by the weight on the other side.

And if there’s too much weight on one side, the lift truck will tip.

To achieve this balancing act, a forklift consists of a:

- Counterweight

- Fulcrum

- Load-bearing mechanism

Let’s discuss these components in more detail.

Counterweight

A forklift’s counterweight is a large metal weight located on the truck’s rear.

Its job is to provide a counterbalance to the load.

It does so by providing more downward force than the load on the front of the truck.

And this prevents the truck from tipping forward when loaded.

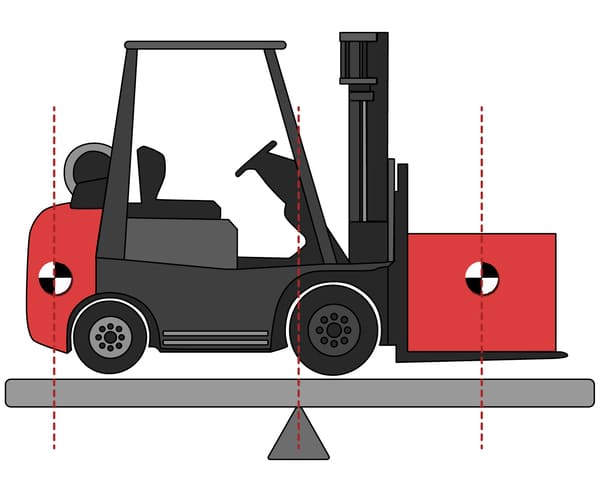

Fulcrum

If you remember back to science class, a fulcrum is simply the point on which a lever rests and pivots.

So what is the fulcrum point on a forklift?

Answer: It’s the front axle.

This is where the load in the front of the truck and the counterweight in the rear strike a balance.

And when that balance is maintained, the forklift is stable and won’t tip.

Load-Bearing Mechanism

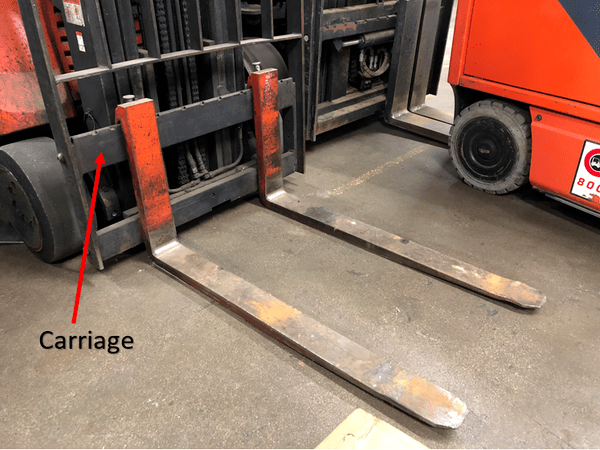

The “load-bearing mechanism” of a forklift is simply the part that handles the load.

Technically, it’s called a “carriage,” which is the part connected to the mast and which the forklift attachment – usually a pair of forks – hangs off of.

If the counterweight is one end of the “seesaw,” then the load-bearing mechanism is the other end.

The Stability Triangle: Everything You Need to Know

Now you understand the basics of how a forklift works – just remember, it’s like a seesaw.

But there’s a bit more to the story that you should understand before we talk about calculating forklift capacities and so on.

And that means covering the “stability triangle.”

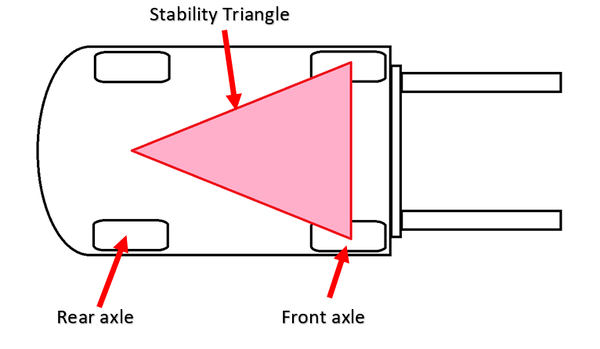

What Is the Stability Triangle?

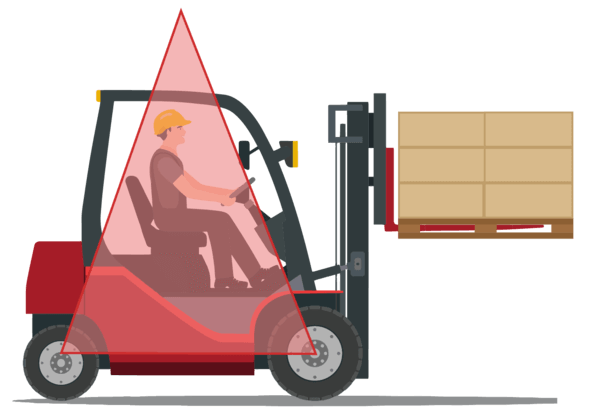

The stability triangle is a concept used to illustrate how a forklift can operate safely without tipping over.

But what exactly is it?

The stability triangle is an imaginary triangle that exists between the center of the rear axle of a forklift and at both wheels of the front axle.

Why is the stability triangle located at these three points?

Because that’s where the forklift’s weight is supported.

Understanding the Stability Triangle

In order to understand the stability triangle – and more importantly, how forklifts are engineered to prevent tip-overs – we need to introduce and define 5 concepts:

- Center of gravity

- Combined center of gravity

- Load center

- Load moment

- Load capacity

So let’s do exactly that.

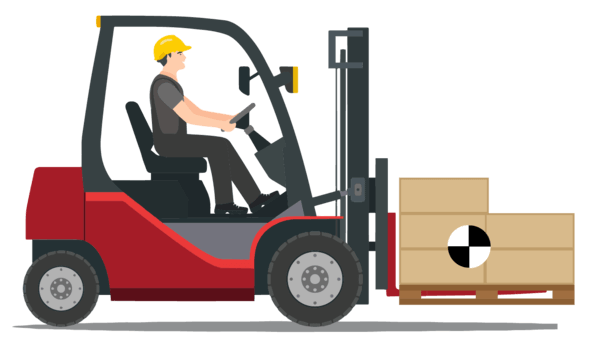

What Is Center of Gravity?

Center of gravity is the imaginary point where all of an object’s weight is concentrated.

In the context of forklifts, the center of gravity exists in two objects:

- The forklift itself and where its weight is concentrated

- The load and where its weight is concentrated

In an unloaded forklift, the center of gravity is usually right below the operator’s seat.

In the load itself, the center of gravity can depend on how the load is constructed.

For instance, in a perfectly square load, the center of gravity is in the direct center of the square:

But on loads that aren’t perfectly square, the center of gravity can lie elsewhere.

For example, take a look at this irregular load:

Here, the weight of the load isn’t concentrated directly in the center.

Instead, it’s further off.

And this has important implications for the safe carrying of this load on a forklift.

We’ll discuss this in more detail in the section How to Maintain Forklift Stability.

What Is Combined Center of Gravity?

We said above both a forklift itself and the load it handles each have their own center of gravity.

But what happens when you pick up the load with the forklift?

Answer: The centers of gravity of both the forklift and the load combine.

Hence, you have a “combined” center of gravity.

So why is this concept important?

Because where that combined center of gravity exists within the stability triangle determines the stability of the forklift as a whole.

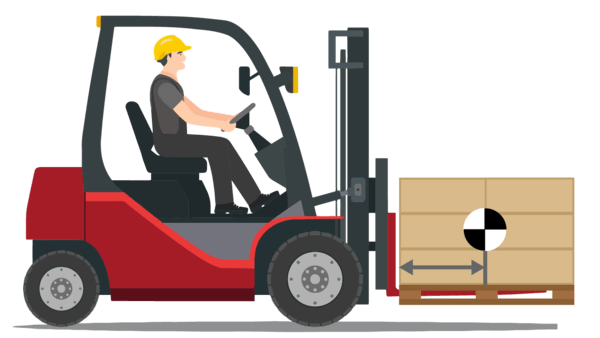

What Is the Load Center of a Forklift?

We’ve just defined two concepts with the word “center” in them.

Now here comes another one related to center of gravity.

But let’s be careful not to get confused between these similar-sounding terms.

Whereas center of gravity is an imaginary point in a load, the load center instead is a measurement.

Technically speaking, it’s the distance from both the horizontal and vertical part of a lift trucks’ forks to the center of gravity of the load on the forks.

Now, most of the time, forklifts handle loads on pallets.

And most standard pallets are 48 inches long.

So, you might be wondering: What is the load center of a 48-inch long pallet?

Assuming that the load is evenly distributed on the pallet, the answer is that it will have a 24-inch load center.

And in fact, most forklifts are rated at a 24-inch load center because 48-inch pallets are so common.

But if the forklift handles longer loads, the load center can be different.

For instance, some forklifts are rated for 36- or 48-inch load centers for this reason.

If that’s the case, it’s important to remember that these lift trucks won’t be able to lift as much weight at these greater load centers.

And that’s because as the load center on the forklift increases, the lifting capacity decreases.

What Is Load Moment?

Let’s use the previous sentence of the last section as our starting point for defining load moment.

Why does the forklift weight capacity decrease as the load center increases?

Answer: Because of an increased load moment.

So, what does load moment mean?

It’s the amount of overturning force applied to a loaded forklift.

Mathematically speaking, it’s the product of the weight of the load multiplied by the load’s distance from the fulcrum (the front axle):

Maximum Load Moment = Weight X Distance

So, what exactly does load moment tell you?

Answer: How much weight you can carry and at what distance from the pivot point you can do so without risking a tip over.

How Does It All Work Together?

We’ve thrown a lot of terms at you in the last couple of sections.

Now, let’s try to put them all together to understand how a forklift can safely lift a load.

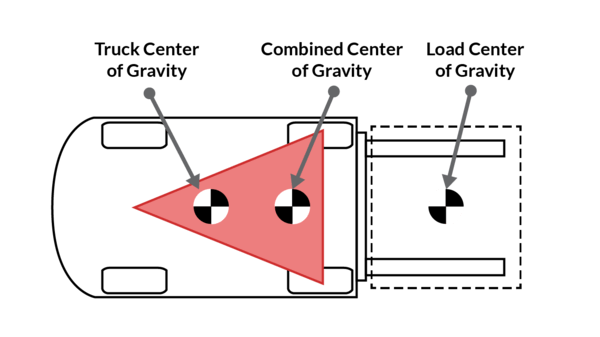

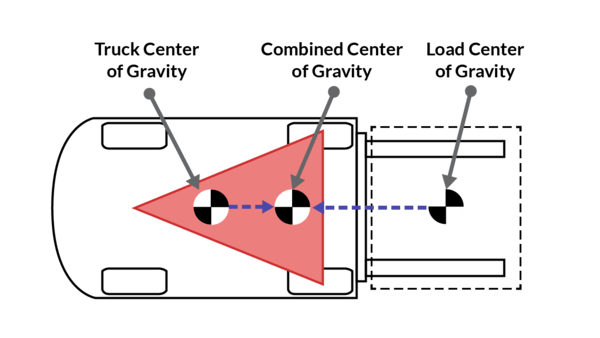

Maintaining Stability within a Triangle

The key concept to understand is that the center of gravity of the truck must fall within the perimeter of the stability triangle.

As we’ve said, an unloaded forklift’s center of gravity is in the center of the forklift – under the forklift operators’ seat.

But as weight is added to the forks, the combined center of gravity moves closer to the front axle.

Once the center of gravity is in line with the front axle, the forklift is at the limit for stability.

And moving forward beyond the front axle will result in an unstable forklift in danger of tipping over.

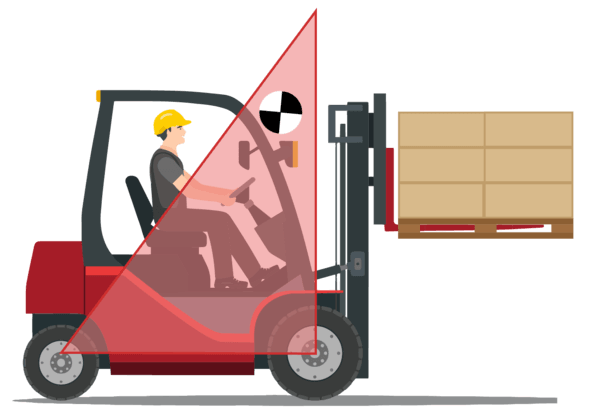

Maintaining Stability within a Pyramid

Now, up to this point, we’ve only been talking about the stability triangle as a 2-dimensional concept between the front and rear axles.

And using this concept, we’ve been able to explain how a forklift can carry loads without tipping.

But what we haven’t explained is how the stability triangle takes into account the namesake function of forklifts: Lifting things.

To do that, we’ve got to expand on our stability triangle concept.

How?

By transforming the stability triangle into a pyramid.

Let’s unpack this a little more.

The stability triangle isn’t actually a triangle.

Instead, it’s a pyramid – one that encompasses the points between the axles but also vertically towards the top of the lift truck.

But how does this pyramid concept help us understand lifting loads?

When a load is lifted, the center of gravity is not only pushed forward toward the front axle – it’s also pushed upward.

And just like the center of gravity cannot go outside the confines of the stability triangle (that is, the front axle), it also cannot go outside the confines of the pyramid.

If you consider a 3-dimensional pyramid, you’ll realize that as you increase in height, you’ll have less area for the center of gravity to go before it goes outside the pyramid.

That’s, of course, because a pyramid has slanted sides which narrow towards the single point at the top.

So, what does this mean?

It means that you won’t be able to lift as much weight at height as you can when the weight is low to the ground.

Thus, that’s why it’s important to always carry the load as close to the ground as possible.

Because a load that’s safe at only a couple inches off the ground may in fact tip the forklift over at a few feet above the ground.

How Much Weight Can a Forklift Lift?

This is one of the most common questions asked about forklifts.

But the answer – like many things in the world of forklifts – is somewhat nuanced.

So let’s cover this question in a little more detail to find the answer.

What Is Load Capacity?

Another way of asking “how much weight can a forklift lift?” is to ask “what is the load capacity of a forklift?”

But when we talk about “load capacity,” this can actually mean either of two things:

- Rated load capacity

- Actual load capacity

And to understand how much a forklift can lift, we need to differentiate between these two terms.

Rated Load Capacity vs. Actual Load Capacity

So, what is a lift truck’s rated capacity?

The rated load capacity is the maximum theoretical weight of load a lift truck can safely lift.

For example, if we talk about a 3,000 lb. capacity 3-wheel forklift, the rated load capacity is 3,000 lbs.

And this is based on engineering calculations and assumptions about the load.

But a forklift’s actual load capacity, on the other hand, is how much weight it can lift in the real world.

And often, the “actual” capacity is different from the rated capacity.

For instance, this is the case when a forklift attachment like a sideshifter is installed.

Or, it’s the case when the load being handled is irregular and thus has a different center of gravity.

Confused?

Let’s go back to our 3,000 lb. 3-wheel forklift.

While the rated capacity may be 3,000 lbs., in actuality, the lift truck probably can’t lift that much weight.

For instance, if it has a sideshifter installed, the capacity drops down (called “de-rate”) to 2,700 lbs.

Why exactly?

Because an installed sideshifter adds extra thickness to the carriage.

And this extra thickness increases the load center, which increases the load moment and thus decreases the lifting capacity.

7 Factors That Affect a Forklift’s Lifting Capacity

We’ve briefly described two factors that can affect the actual load capacity of a forklift.

Let’s go through these factors and others in more detail.

1. Lifting Height

The higher the lifting height, the less weight can be lifted.

This is because the center of gravity increases.

Recall that the stability triangle is actually a pyramid.

And as the load is lifted, the center of gravity shifts forward and up.

At some point, the center of gravity will move outside the pyramid.

And when that happens, the lift truck can no longer safely lift the load without the risk of tipping over.

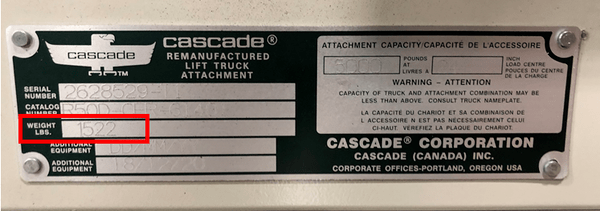

2. Attachments

Adding an attachment to your forklift can lower the lifting capacity.

Why?

For two main reasons.

One is because the attachment adds weight to the load mechanism.

As such, it subtracts from the truck’s lifting capacity.

Another reason is that the attachment extends forward the load center.

In technical terms, the distance the attachment extends the load center forward is called the “effective thickness” of the attachment.

And this causes the load moment to increase and consequently decreases the lifting capacity.

3. Load Length

Remember that most forklifts are by default rated for loads with a 24-inch load center.

But if handling loads longer than that, the load center will increase.

And that causes the combined center of gravity to shift forward as well.

The consequence?

A reduction in lifting capacity.

4. Load Distribution

That 24-inch load center we’ve been on about?

Remember that it’s based on a load where the weight is evenly distributed.

But with loads that aren’t evenly distributed, the center of gravity moves forward or side-to-side.

And not only does this reduce the lifting capacity, but it also introduces instability into the forklift.

That’s why you should place the load so that the heaviest part is closest to the fork face.

5. Wheel and Tire Type

Different tire types, sizes, and tread widths can increase or decrease a forklift’s lifting capacity.

For example, cushion tires provide better capacity retention than pneumatic tires.

And dual tire configurations give forklifts higher lifting capacities than single tire configurations.

Furthermore, tires with wider treads increase a forklift’s weight capacity.

This is done by creating a broader stance that improves the truck’s stability.

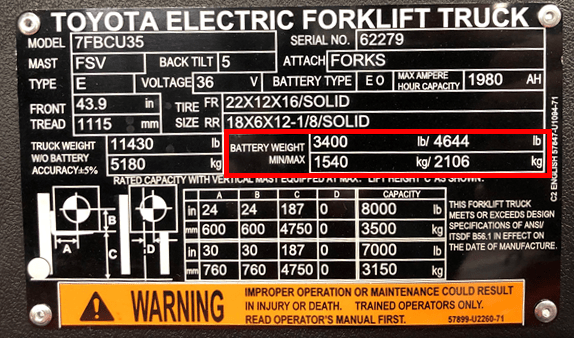

6. Battery Weight

Internal combustion forklifts rely on the counterweight at the rear to stabilize the lift truck.

And while some electric forklifts do have counterweights, these don’t provide all the counteracting force required for stabilization.

Instead, the battery performs this function.

That’s why electric forklifts have a minimum battery weight requirement:

And installing a lighter-weight battery can reduce the lifting capacity and cause serious safety concerns.

So, you must make sure to check the lift truck’s data plate to ensure that the battery installed is at least as heavy as the plate requires.

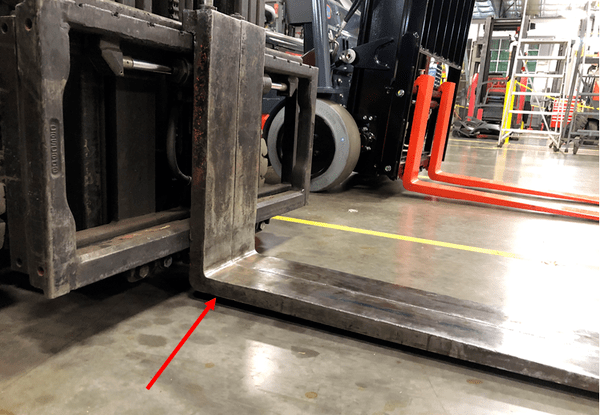

7. Fork Wear

A forklift loses around 20% of its lifting capacity with every 10% of erosion of the fork’s heel thickness.

This also applies to other components subject to wear and tear, like tires.

As such, it’s important to regularly inspect your forks and tires for wear.

And be sure to replace them when their wear limits are exceeded.

What Happens If You Exceed Your Forklift’s Capacity?

Overloading a forklift is a safety risk and can result in forklift accidents, injury, or death.

So it’s vital to know how much weight your forklift can safely lift to prevent these hazards.

These hazards include:

Tip-Overs

Tip-overs are the main cause of forklift casualties.

As you now understand, tip-overs happen when the center of gravity leaves the stability pyramid.

Loss of Steering

An overloaded forklift can result in the steer tires losing contact with the ground.

If that happens, the forklift operator won’t have control over the direction of the lift truck.

And that can result in collisions with other equipment, infrastructure, product, or even personnel.

OSHA Fines

When you overload and get an accident, you risk getting OSHA fines and other consequences for poor material handling practices.

These fines are nothing to shrug off either.

That’s because they can be as much as $136,532 per violation for willful or repeated infractions.

How to Maintain Forklift Stability

According to OSHA’s rules for forklift capacity, forklifts shall only handle loads within their rated capacity for both man and machine safety.

Some applicable OSHA forklift capacity rules include:

-

The operator shall see that all markings and nameplates are in place and are properly maintained in a legible condition. The nameplate stores the rated capacity. – 1910.178(a)(6)

-

Only handle safely arranged or stable loads. Exercise caution when handling off-center loads. – 1910.178(o)(1)

-

Only loads within the rated capacity of the truck shall be handled. – 1910.178(o)(2)

-

The long or high (including multiple-tiered) loads which may affect capacity shall be adjusted. – 1910.178(o)(3)

Besides specific rules, OSHA also recommends a variety of practices to ensure you properly load your forklift.

Following these recommendations can help ensure your forklift maintains the right stability and balance:

-

Distribute the weight evenly when carrying irregular-sized loads

-

Keep the center of gravity of the load as near as possible to the center going horizontally across the forks

-

Keep the center of gravity of the load as near to the front wheels as possible

-

Do not operate a forklift if the back wheels begin to lift off the ground

-

Handle only stable or safely arranged loads. Exercise caution when handling off-center loads that cannot be centered

-

Tilt the mast forward cautiously when positioning the load onto the stack

-

Never travel with the load elevated. Instead, keep the center of gravity of the load as low to the ground as possible (4 to 6 inches)

-

Tilt the mast back and position the heaviest part of the load against the carriage

-

Travel with the mast tilted back to stabilize the load

Common Forklift Capacities

Now that we’ve covered everything you need to know about forklift load capacity, let’s talk about the rated capacities for certain types of forklifts.

What Is the Largest Forklift Capacity?

Wondering what the largest forklift capacity is?

Answer: It’s 198,000 lbs.

This record belongs to the Swedish manufacturer Kalmar and is verified by the Guinness Book of Records.

What are the Capacities for Common Forklifts?

Some of the forklift capacity ratings for common types of forklifts are:

| Forklift Type | Rated Capacity Range |

|---|---|

| Electric 3-Wheelers | 3,000 lb. – 5,000 lb. |

| Electric 4-Wheelers | 3,000 lb. – 12,000 lb. |

| Electric Stand-Up Riders | 3,000 lb. – 5,000 lb. |

| Electric Reach Trucks | 3,000 lb. – 4,500 lb. |

| Electric Order Pickers | 3,000 lb. |

| Internal Combustion Sit-Down Counterbalance | 3,000 lb. – 158,500 lb. |

| Rough Terrain Forklifts | 5,500 lb. – 35,500 lb. |

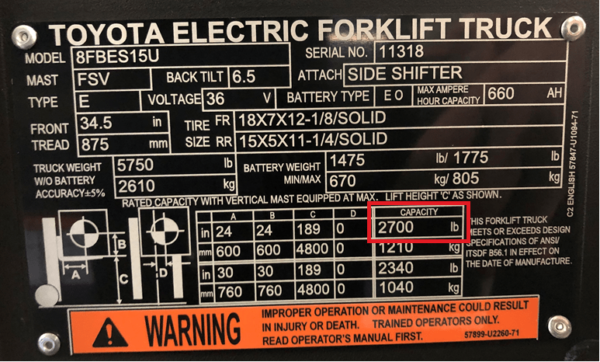

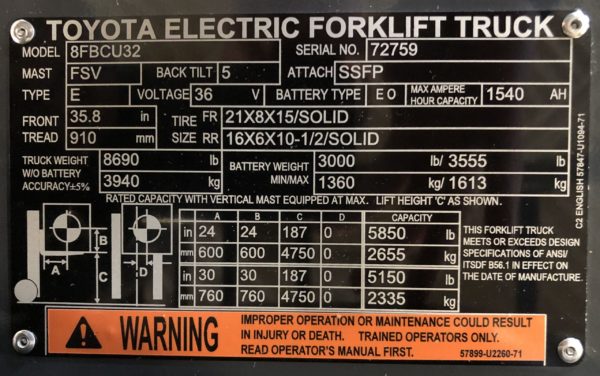

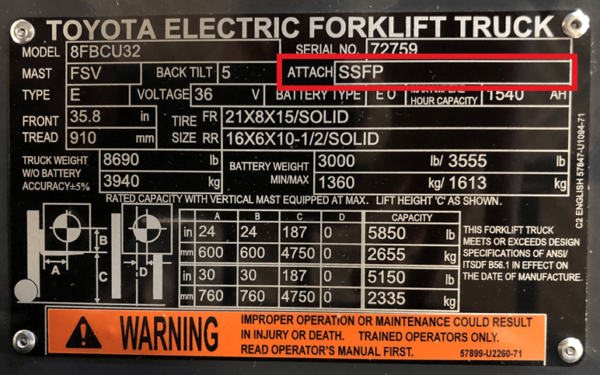

Forklift Capacity Plate: What It Is and How to Read It

Where can you find the load capacity of a powered industrial truck?

Answer: On the capacity plate.

Also called “nameplates,” “data plates,” or “data tags,” these are plaques installed on forklifts that list essential information about the truck, including:

- Model and serial number

- Fuel type

- Installed attachments

- Tire size

- Battery weight requirements (if electric)

- Lifting capacities

You’ll need to be familiar with your lift truck’s data tag.

This is because it’s your go-to information source for how much weight your forklift can safely handle.

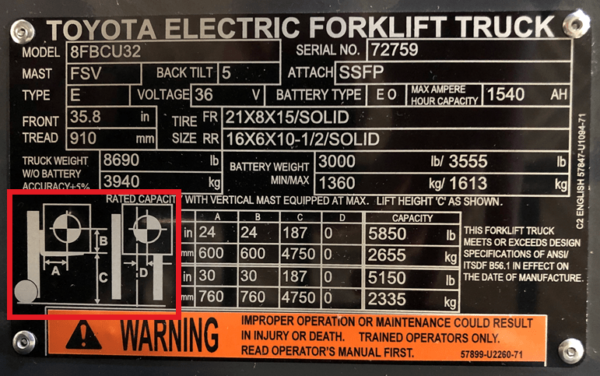

How to Read a Forklift Load Capacity Chart

If you’ve never seen a forklift load capacity chart, you’re probably wondering how to read it.

Let’s go through just that.

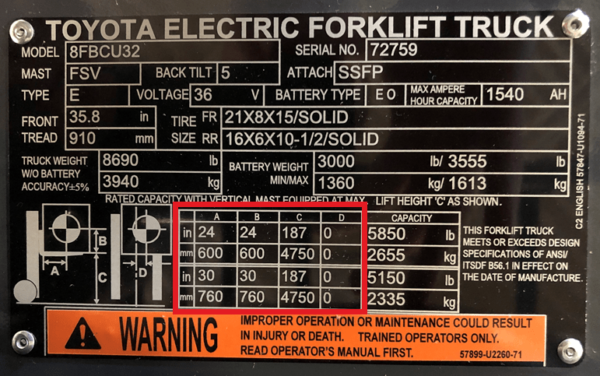

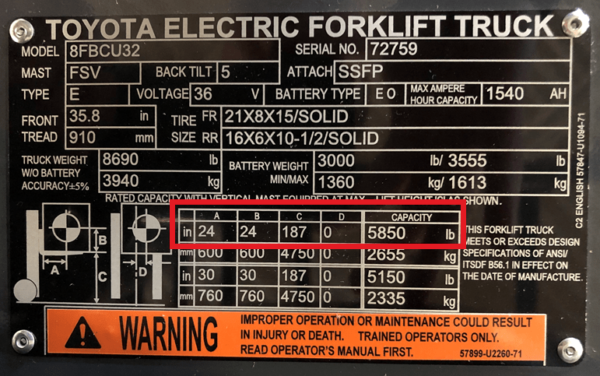

The first thing to notice is the drawings on the bottom left corner of the tag.

There are two images:

The far left image is a side-view of the mast, forks, and load.

The image on the right is a top-down view of the forks and the load.

Now, notice that in both images, there are a series of letters: A, B, C, and D.

These correspond to values in the table to the right:

The letter “D” from the top-down image corresponds to a laterally-offset load center.

In other words, it’s meant to tell you the load capacity when the load is concentrated off to one side.

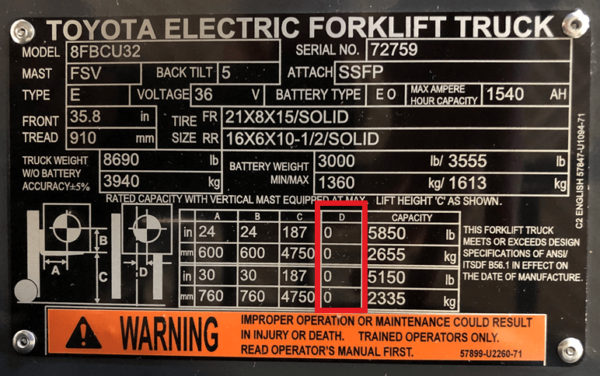

Now, notice that in the table, the values for “D” are 0:

That means this truck isn’t rated for laterally-offset loads.

So we’ll skip that image.

Let’s focus back on the far-left side image and the letters contained within it.

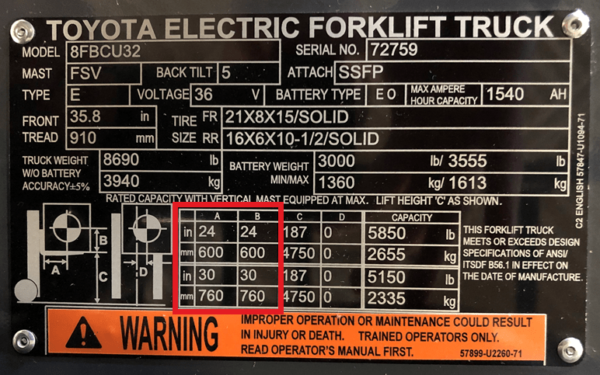

The letters “A” and “B” correspond to the load center of the load.

That is, both the longitudinal and vertical load centers.

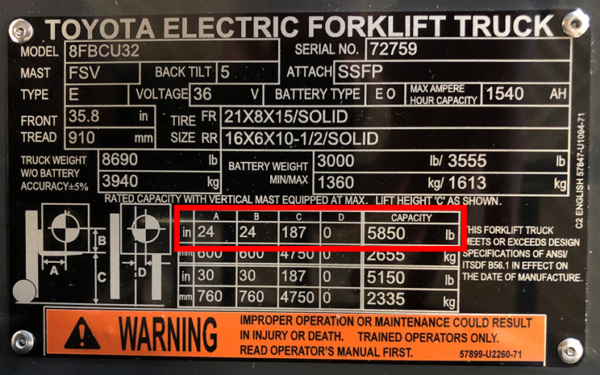

In the table under the “A” column, we can see that the value for “A” and “B” are both 24-inches (or 600 mm):

This means that the center of gravity of the load is perfectly concentrated at 24-inches.

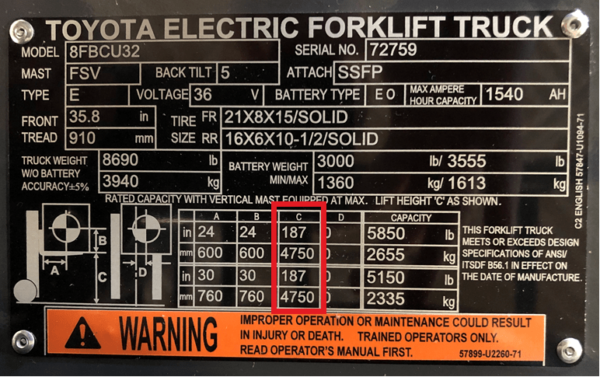

Let’s look at the letter “C” now.

This indicates the lift height.

Looking at the table, this corresponds to a 187-inch (or 4,750 mm) lift height:

Now, let’s put all these values together to understand what this capacity chart is telling us.

If we take A, B, and C together, we can see that this forklift can handle a weight of 5,850 lb. at a height of 187-inches – as long as the center of gravity of the load is exactly at 24-inches:

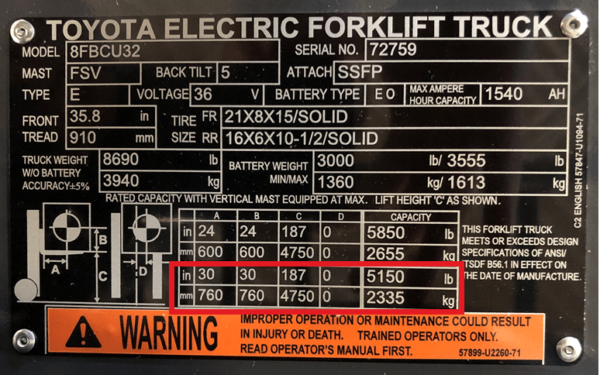

But this changes if we increase the load center to 30-inches.

In that case, the capacity at 187-inches tall is 5,150 lbs:

Now, this truck has a rated capacity of 6,000 lb.

So, why isn’t the actual capacity 6,000 lb.?

Recall that attachments can decrease the lifting capacity.

In this forklift’s case, it has a sideshifting fork positioner attachment:

Because of that, the truck can lift 150 lb. less than the rated capacity at a 24-inch load center and 850 lb. less at a 30-inch load center.

How to Calculate the Capacity of Your Forklift

Finally, we’re ready to answer the question: How do you calculate the load capacity of a forklift?

Now, if you have a load whose center of gravity is the same as your forklift’s rated load center, calculating forklift load capacity it’s pretty straightforward.

You just look at the capacity data tag to determine what weight the lift can handle:

From the example above, you can lift 5,850 lbs. to a height of 187-inches if the load center is at 24-inch.

But if you have a load that isn’t at the specified load center, it becomes a little more involved.

Fortunately, OSHA provides a field calculation to estimate the safe loading capacity of a forklift in these situations.

The gist of this calculation is that you use the ratio of the rated load center to the actual load center then multiply it by the truck’s rated load capacity.

Here’s what that calculation looks like:

Rated Load Center ÷ Actual Load Center x Truck Rated Load Capacity = Actual Forklift Capacity

Let’s consider an example of this calculation to determine how much can a 5,000 lb. forklift lift.

To calculate how much a 5,000 lb forklift can lift with an actual load center of 28 inches and a rated load center of 24 inches, you’d do the following:

- 24-inch (Rated Load Center) ÷ 28-inch (Actual Load Center) = 0.857

- 0.857 x 5,000 (Truck Rated Load Capacity) = 4,285 lbs. (Actual Forklift Capacity)

Now, if you don’t want to manually calculate your forklift’s capacity, there’s good news.

You can use Global Machine Brokers’ forklift lifting capacity calculator to do it for you.

Just type in your values and the calculator will return your lift truck’s capacity automatically.

Conclusion

There you have it: Everything you need to know about forklift weight capacity.