This article has everything you need to know about forklift data plates, including:

-

What a data plate is

-

Why they’re important

-

What is included on them

-

How to read a forklift data plate

Let’s get started!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points:

- A forklift data plate is a placard installed on lift trucks that gives important information about the truck

- They’re used to tell operators how much weight the truck can safely carry, how high it can lift it, any attachments that are installed, and what the fuel type is

- They’re also important because service personnel can reference them when determining repair actions, ordering parts, and replacing tires

- Forklifts must always have a data plate installed and it must be kept legible and in otherwise good condition

- Basic information you’ll find on a data plate includes the:

- Model and serial number

- Truck weight

- Lifting capacity

- Load center

- Maximum lift height

- Any attachments that are installed

- You may also see additional information such as:

- Minimum and maximum battery weights (for electric forklifts)

- Truck voltage (for electric forklifts)

- Mast type

- Tire sizes and type

- Special design features

What Is a Forklift Data Plate?

A forklift data plate is a placard installed on lift trucks to provide information about the design, configuration, and limitations of the truck.

Other names for data plates include:

-

Capacity plate

-

Nameplate

-

Weight plate

-

Capacity load plate

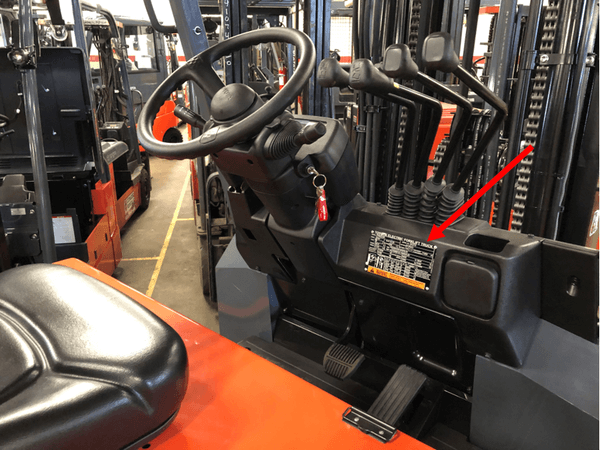

Where Is the Forklift Data Plate?

Generally, the data plate is made of metal and riveted onto the forklift’s body, usually on the instrument panel.

The exact forklift data plate location is typically on the cowl (dashboard) and near the hydraulic controls.

Sometimes, you can also find them on the engine hood next to the operator’s seat.

Why Is the Data Plate Important?

Because they provide forklift operators with a simple and easy way to determine how much weight a forklift can handle.

Beyond that, data plates list important information for forklift owners as well as support staff.

This includes folks like parts personnel and service technicians at dealerships and repair centers.

What exactly that information is and how it helps is something we’ll cover in the section called What Useful Information Can Be Found on a Capacity Plate?

Can You Operate a Forklift Without a Data Plate?

No.

OSHA regulation 29 CFR 1910.178(a)(6) requires that forklifts be outfitted with a data plate at all times.

Furthermore, forklift nameplates must always be legible.

“The user shall see that all nameplates and markings are in place and are maintained in a legible condition.”

OSHA Standard 1910.178(a)(6)

So, operators should never operate a forklift if the nameplate is missing, damaged, or illegible.

Where Can You Get a Forklift Data Plate Replacement?

You generally have 2 places that can provide a new data plate:

- An authorized dealership

- A professional engineering firm

Your first – and easiest – way is to contact the dealership closest to you that deals with the same manufacturer as your forklift.

But if that’s not an option, you can contact a professional engineering firm for a replacement.

One example is Professional Forklift Engineering Services in South Carolina.

How Much Does a Forklift Data Plate Replacement Cost?

Expect to pay anywhere from $150 to $300 or more.

What Useful Information Can Be Found on a Capacity Plate?

We’ve established that all forklifts have data plates.

But not all forklift data plates are the same.

Instead, they can differ depending on the manufacturer, model, and type of forklift.

That said, there are some basic requirements that all forklift data plates must have, per OSHA and ANSI standards.

Let’s go through what exactly those minimum requirements are.

Minimum Forklift Data Plate Requirements

OSHA and ANSI mandate that all lift truck data plates must include the following information:

-

Model and serial number

-

Truck weight

-

Lifting capacity and load center at the maximum lift height

-

Attachment type (if installed), including the combined weight of the truck and attachment and the weight capacity at the maximum lift height

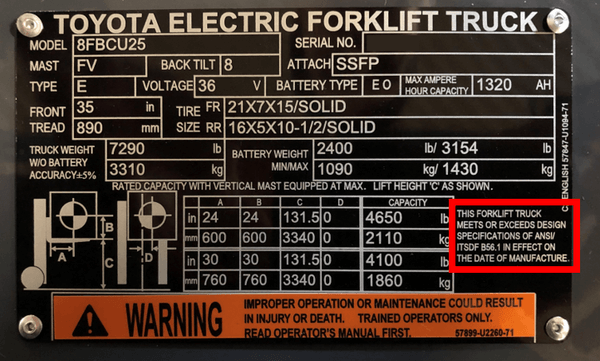

In addition to the above, data plates must also signify that the lift truck follows industry standards, including:

-

Compliance with the ANSI B56.1 standard

-

The type of truck according to the rules from Underwriter Laboratories and Factory Mutual Research Corporation

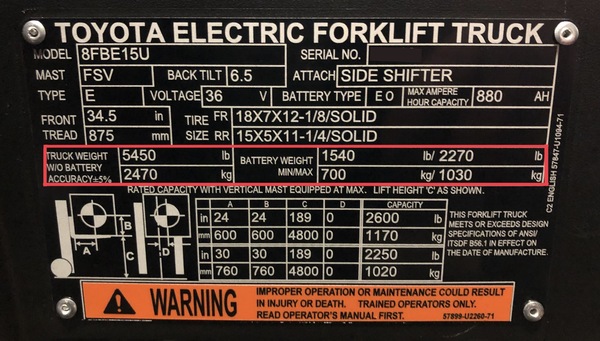

Now, electric forklifts have their own additional requirements as well, including:

-

Truck weight without the battery

-

Minimum and maximum weight of acceptable batteries

-

Truck voltage

-

Maximum rated amp-hour capacity

-

Type of battery (E, EE, EO, or EX)

We’ll cover exactly what these indicate below in the Fuel Type section.

Additional Information on Forklift Data Plates

Now, as we’ve said, the above are only the basic requirements.

But many lift trucks have much more information on the data plate.

So let’s cover what that is.

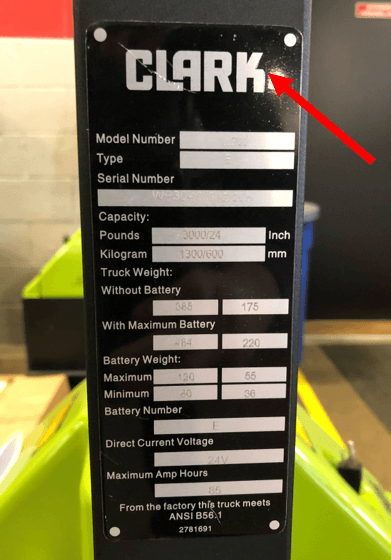

Manufacturer

This indicates the lift truck manufacturer, whether it be Toyota, CLARK, Hyster, Yale, or another brand.

This information is important because manufacturers often include functionalities specific only to their truck models.

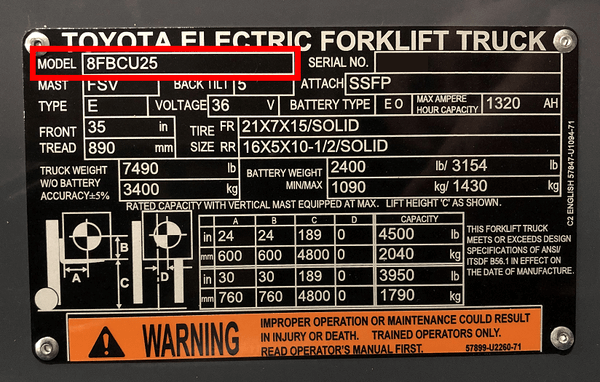

Model Number

This is like a “cheat sheet” for your forklift.

It tells you important information at a glance, including the truck’s series, fuel type, tire type, and lifting capacity (in kilograms).

For example, let’s take a Toyota model 8FGCU25 forklift:

- 8 = The lift truck series

- F = Designation “forklift”

- G = Gas-powered (can be either gasoline, LPG, CNG, or dual fuel under this designation)

- C = Tire type (cushion in this case)

- U = Country of manufacture (United States)

- 25 = Rated capacity in kilograms (abbreviated from 2,500 kg, which equals 5,000 lbs.)

Besides serving as your cheat sheet, the model number is also essential for communicating with dealers and repair personnel for technical assistance.

For instance, ordering the right parts requires knowing the forklift model number.

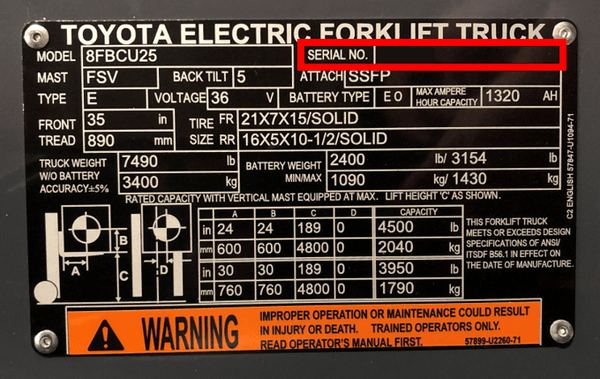

Serial Number

This is just like the vehicle identification number (VIN) on a road vehicle.

And like the model number, it helps repair personnel narrow down technical information about your lift.

That can include such information as if it has a different design than other lift trucks in the same model series.

Using the serial number, a technician can match parts to ensure they’ll work with that particular truck.

Looking for a Toyota Forklift Serial Number Lookup?

Unfortunately, this doesn’t exist on the open web.

But, we’re here to help.

Simply contact us and we can help you narrow down the age of your lift truck, order parts, or advise on service needs.

Truck Weight

You’d think this one would be pretty self-explanatory.

And it is, but with some nuance.

Recall that electric lift trucks have slightly different data plate information requirements.

And an important difference is in the weight of the truck.

For electrics, the truck weight consists of the chassis weight, including any attachments, and excluding the load.

But – importantly – the weight excludes the weight of the battery.

So, if you need to know the total weight of your electric truck, you’ll need to add the truck weight listed on the data tag to the weight of the battery (which is found on the battery itself).

How Much Do Forklifts Weigh?

The following table lists the weights for several models of Toyota forklifts:

| Model | Truck Type | Lifting Capacity | Chassis Weight | Battery Weight | Total Weight |

|---|---|---|---|---|---|

| 8FBE15U | 3-wheel electric | 3,000 lbs. | 4,620 lbs. | 2,040 lbs. | 6,660 lbs. |

| 8FBCU20 | 4-wheel electric | 4,000 lbs. | 6,260 lbs. | 2,925 lbs. | 9,185 lbs. |

| 9BRU18 | Reach truck | 3,500 lbs. | 6,100 lbs. | 1,945 lbs. | 8,045 lbs. |

| 8FGCU25 | Internal combustion, cushion-tire | 5,000 lbs. | 8,000 lbs. | N/A | 8,000 lbs. |

| 8FGC45U | Internal combustion, cushion-tire | 10,000 lbs. | 14,510 lbs. | N/A | 14,510 lbs. |

| 8FGC70U | Internal combustion, cushion-tire | 15,500 lbs. | 20,490 lbs. | N/A | 20,490 lbs. |

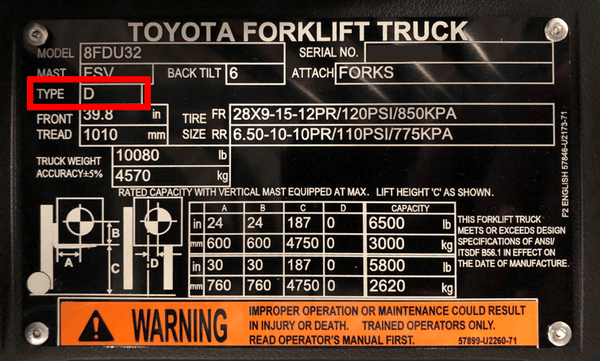

Fuel Type

This shows whether the truck is powered by:

-

Electricity (E)

-

Gasoline (G)

-

Liquid propane gas (LPG)

-

Diesel (D)

-

Compressed natural gas (CNG)

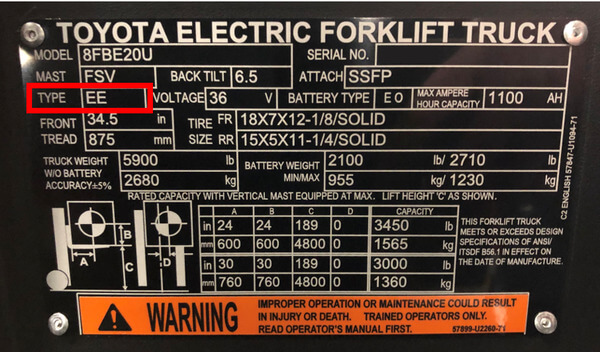

Special Fuel Designations

The data plate fuel type section can also indicate if the forklift has a special design.

For example, let’s say the tag shows “EE.”

That means the lift truck is manufactured to run on electricity, but with extra safeguards to protect against fires and explosions.

Thus, an EE-rated electric fork truck can be used in locations where a basic electric forklift isn’t considered suitable.

For a full list of these special designations and a definition of each, see OSHA standard 1910.178(b).

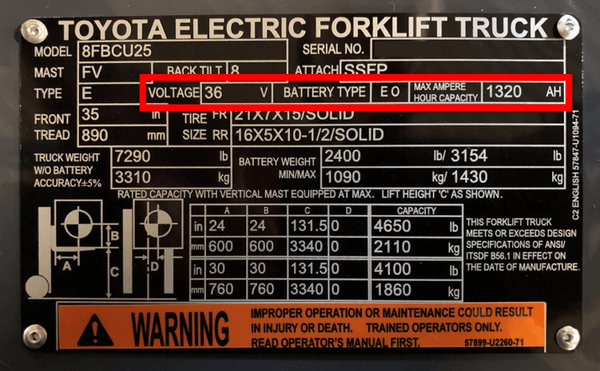

Fuel Information Included Only on Electric Forklift Data Plates

Most forklifts are liquid propane gas (LPG) powered, followed by electric.

And again, electric forklifts have additional sections regarding the fuel that other truck models don’t.

This includes data like:

-

Voltage

-

Amp-hour rating

-

Battery weight

Now, why exactly do electric forklifts need this extra information?

The main reasons are to ensure:

-

The battery matches the voltage that the truck is set up for

-

The battery voltage matches the charger voltage

-

The battery amp-hour rating (which is a measure of the current produced) is within the range of what the truck can handle

If there’s a mismatch between any of these parts, it can result in damage to the battery, truck, and/or charger.

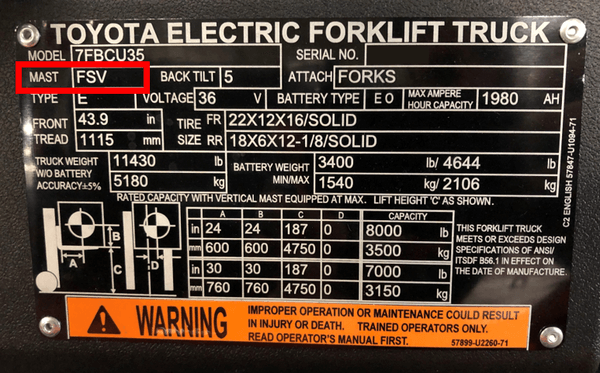

Mast Type

If you’re unsure, a forklift mast is the vertical part of the forklift, at the front, that actually does the lifting.

And lift trucks have different types of masts, depending on the model.

The most common mast types are:

-

3-stage (sometimes called FSV or TSU)

-

2-stage (also called V or FV)

-

4-stage (aka QFV)

And within the data tag, the type of mast will be listed, usually with the abbreviation listed above shown.

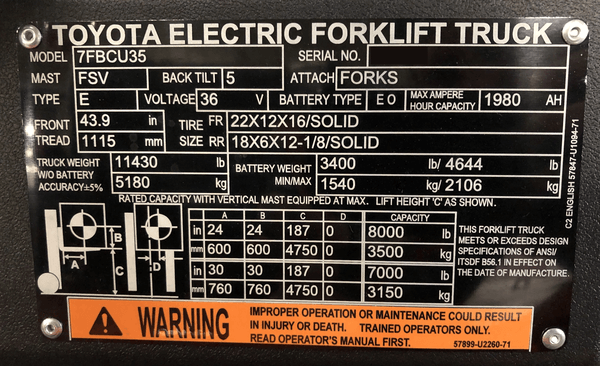

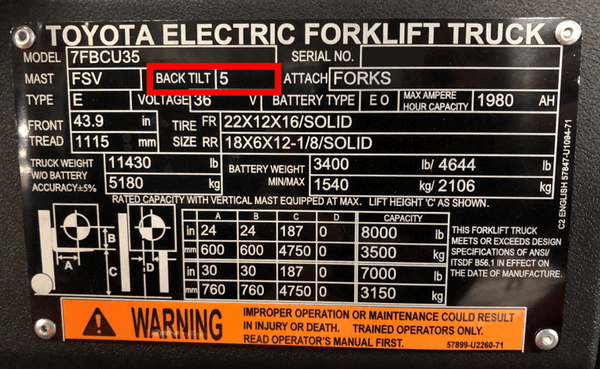

Back Tilt

Back tilt is related to the mast.

Specifically, it tells you how far backward (that is, toward the operator) the mast can tilt.

This value is shown in degrees, with common back tilts being 5 and 6.5 degrees.

The degree of back tilt on this Toyota 7FBCU35 data plate

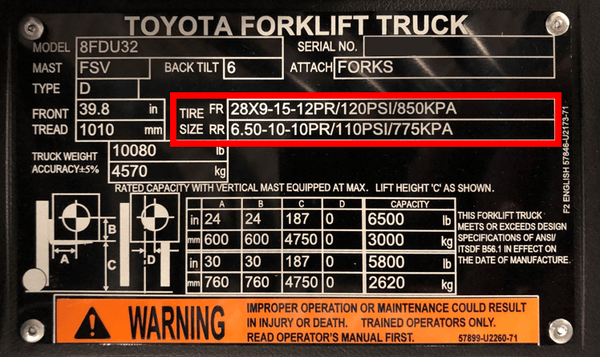

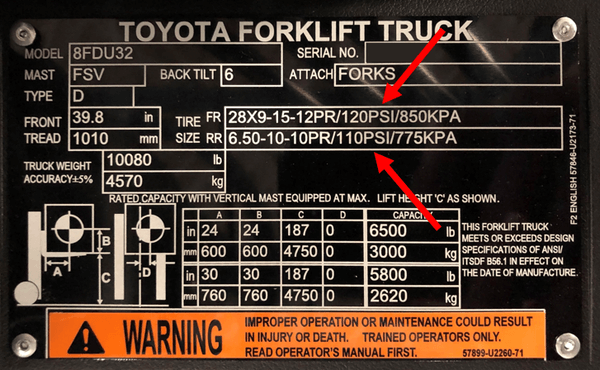

Tire Information

Forklift nameplates also include various bits of important information on tires.

Let’s go through what that information is.

Front Tire Tread

The front tread of a forklift indicates how wide its front wheels are.

And this has an effect on how wide overall the forklift is.

Therefore, the front tread measurement is like a footprint.

That is, it helps operators understand the space a forklift will need in a workplace.

Tire Type and Size

Not all forklift tires are the same.

Some forklifts can only work with certain types of tires.

For instance, if you see “SOLID” listed on a nameplate, it means the truck is designed for cushion tires.

If the lift truck has air-filled tires, then you’ll commonly see the recommended PSI.

Attachments

Anytime a lift truck has an attachment installed on it, it must be listed on the data plate as well.

One important reason for this is that attachments reduce lifting capacity.

In fact, OSHA requires that the weight of attachments plus the weight of the truck itself be listed on the data plate in standard 1910.178(a)(5).

If it’s not, you’ll need to get a new plate from the manufacturer.

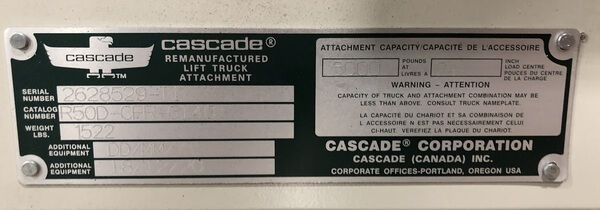

Forklift Attachment Data Plates

Forklift attachments have their own data plates, separate from the lift truck itself:

And these data plates must include certain bits of information, including:

-

Model number

-

Serial number (for attachments with hydraulics)

-

Year of manufacture

-

Maximum hydraulic pressure

-

Weight

-

Load center

-

Capacity

-

Warning to consult the truck data plate for actual capacity, since the capacity may be less than what’s shown on the attachment nameplate

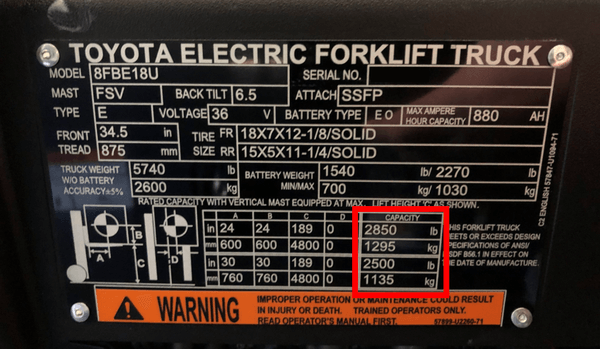

Forklift Weight Capacity Chart

A forklift truck’s rated capacity is stamped on this section of the data plate.

Now, the rated capacity of a lift truck is based on several different factors.

And you’ll need to understand what those factors are to really know how much the truck can lift.

We’ve covered this topic in much more detail in our article called Forklift Weight Capacity: Everything You Need to Know.

But let’s quickly go through those factors here as well.

How to Read a Forklift Load Capacity Chart

You’ll find the following data on the load capacity chart:

-

Load Center

This is the distance of the center of gravity of the load, measured horizontally from the front of the forks as well as vertically from the top of the forks. Most lift trucks are rated with a 24-inch load center. And the rated capacity is based on that distance. The rule of thumb is that the greater the distance, the less the lift truck can lift

-

Maximum Lift Height

This is how high up the forklift mast can go. It depends on the mast installed on the lift (which, recall, you can find in the “Mast Type” section of the nameplate). And the higher the maximum lift height, the less weight the truck can lift

-

Load Capacity

This is how much weight the forklift can actually lift. It is calculated based on any installed attachments, the load center, and the maximum lift height

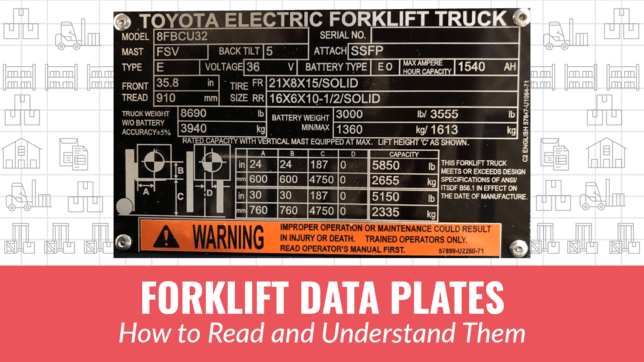

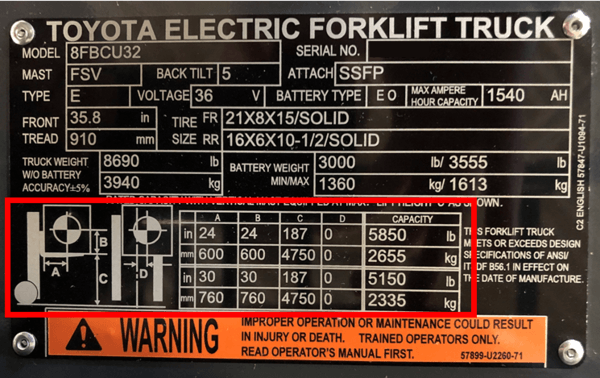

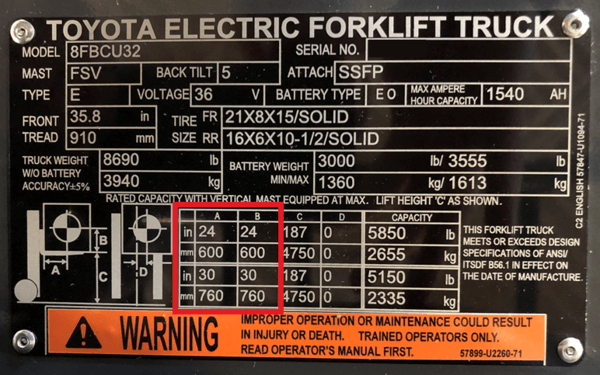

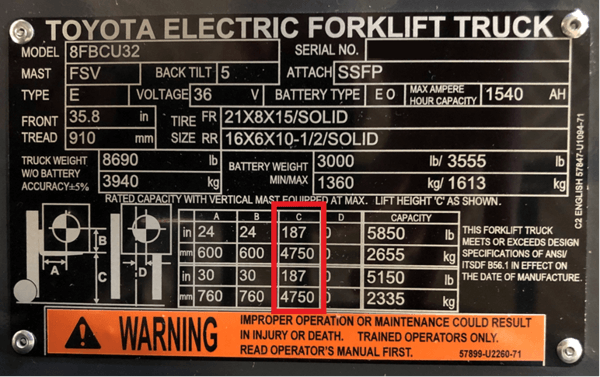

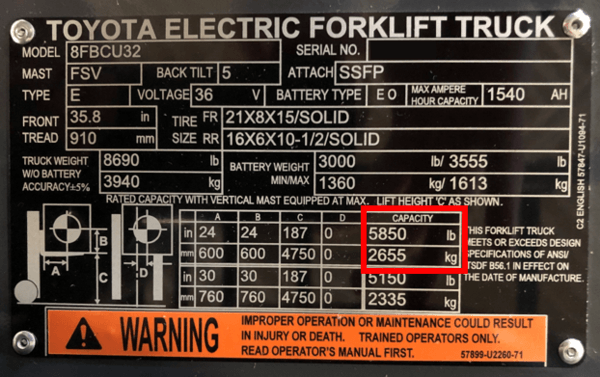

Let’s take a look at a forklift data plate example to see how these factors come together.

The letters “A” and “B” correspond to the load center, which is 24 inches.

Letter “C” corresponds to the lift height, which is 187 inches.

Given those 3 values, the lifting capacity is 5,850 lbs.

Now, this truck has a maximum lifting capacity of 6,000 lbs.

So, why can’t it lift that much weight?

Because of the attachment.

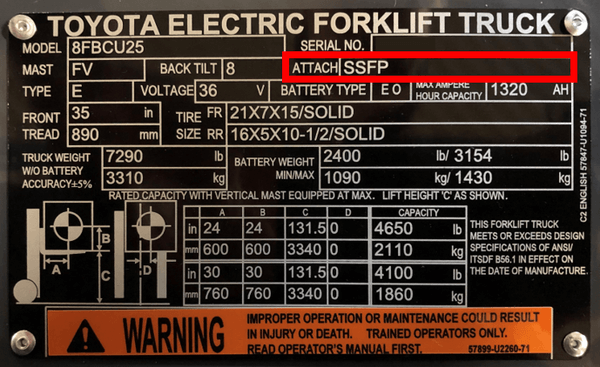

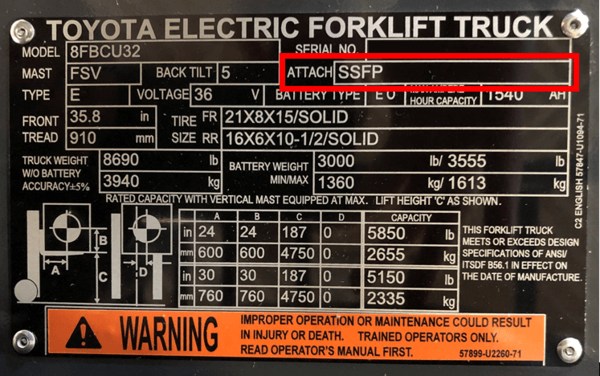

Notice that this truck has a sideshifting fork positioner installed (labeled as “SSFP”):

And because attachments bring down the lifting capacity and extend the load center, the truck is rated to lift 150 lbs. less than the maximum lifting capacity.

7 Forklift Data Plate Tips

Let’s summarize what we’ve covered and add a few other helpful tips and best practices concerning forklift data plates:

-

Make sure the data plate is installed

Ensure all lift trucks in your fleet have a data plate installed. If they’re missing, contact your local dealership for a replacement

-

Maintain the data plate

Maintenance personnel should regularly check the data plates for readability and any changes to the forklift’s configuration, such as attachments

-

Know how to read the data plate

All persons that work on or with forklifts – such as operators, supervisors, and maintenance personnel – should know how to read and understand forklift data plates

-

Review data plates frequently

Operators should form a habit of reviewing the data plate before the start of each shift. That way, they can determine the truck’s lifting capacity and be aware of any new attachments installed

-

Understand attachments

Operators must understand how attachments affect the weight lifting capacity of their forklifts. They should also understand how different load types and configurations can affect lifting capacities as well. For instance, handling extra-long loads and loads with an uneven center of gravity can lower the truck’s rated capacity

-

Check batteries

Ensure that the batteries of all electric lift trucks are within the proper weight range listed on the data plate

-

Confirm the data plate’s correctness

Whenever you buy or rent a forklift, ensure the data plate is correct before you use it. You never know how the previous owner handled the lift

Conclusion

That’s it: You now know everything you need to know about forklift data plates.