This article covers everything you need to know about forklift controls.

In it, you’ll learn:

- The different types of controls

- What each control does

- And much more…

Let’s dive in!

Forklift Control Panels: An Overview

Many people wonder: Are all forklift controls the same?

The answer is “No.”

They differ depending on the type of lift truck.

Overall, there are 3 types of forklift control configurations:

- Sit-down counterbalance controls

- Stand-up rider controls

- Hand-controlled truck controls

Let’s briefly discuss each layout.

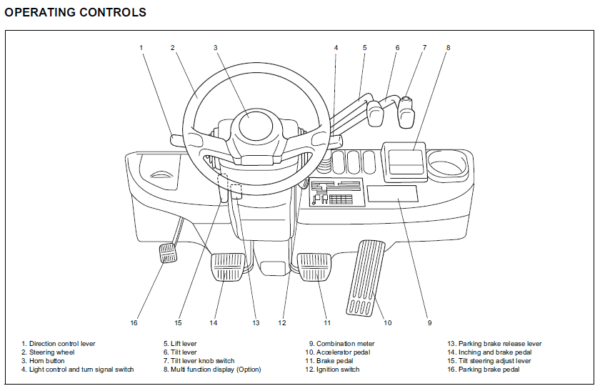

Sit-Down Rider Controls

Sit-down forklift controls are found in internal combustion and electric forklifts.

Controls on these trucks include:

- Steering wheel and horn

- Pedals

- Hydraulic levers

Stand-Up Rider Controls

Stand-up rider controls are found on stand-up counterbalance trucks, reach trucks, and order pickers.

Controls on these trucks include:

- Joystick (combination of gear select, accelerator, horn, and hydraulic functions)

- Steering wheel

- Deadman pedal

- Emergency stop button

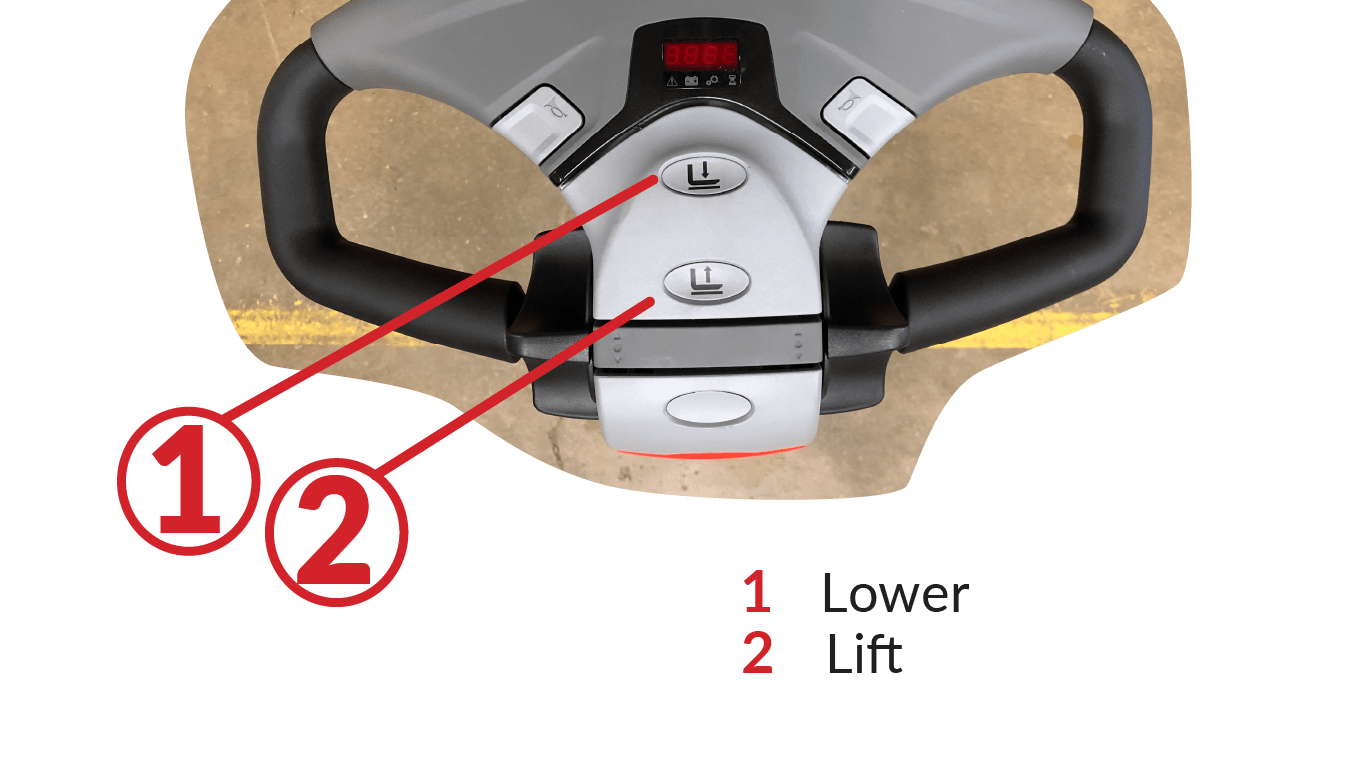

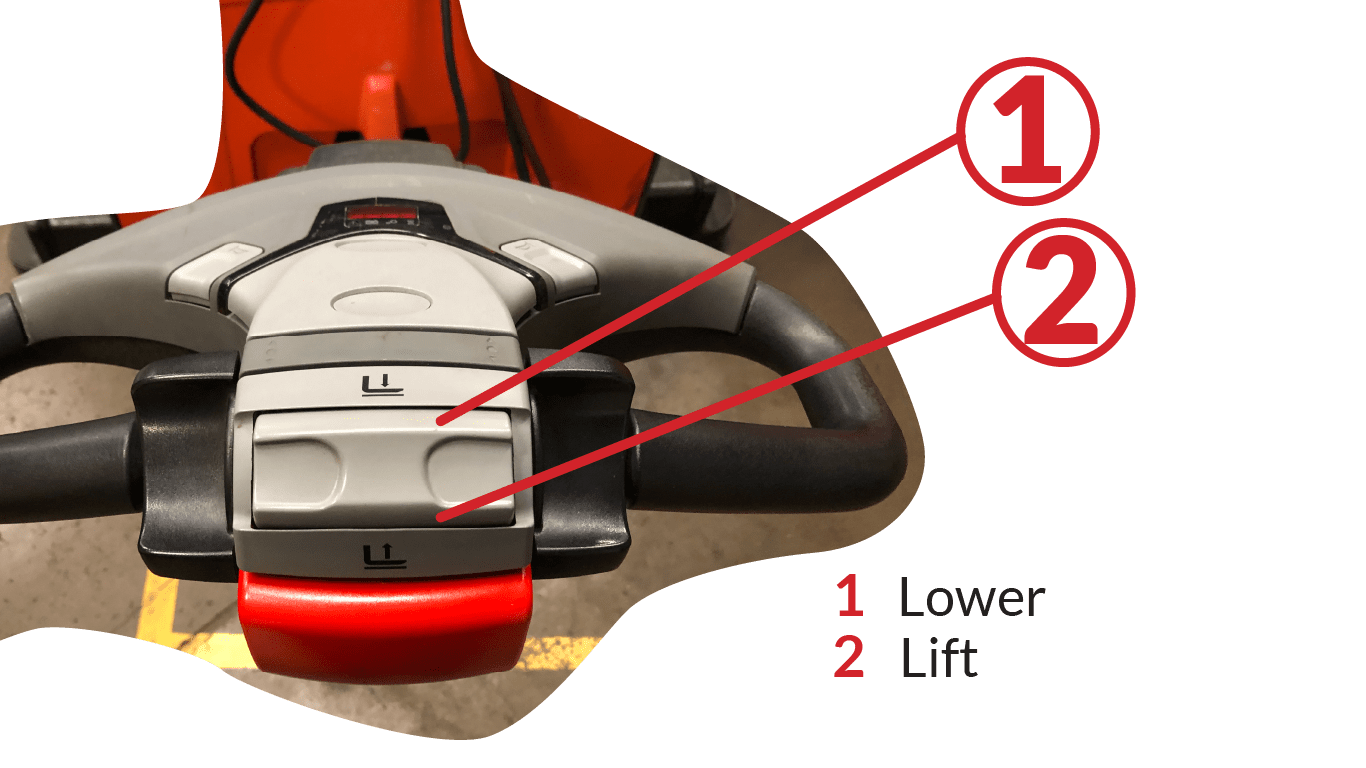

Hand-Controlled Truck Controls

Hand-controlled truck controls are found on electric pallet trucks and stackers.

They are clustered on the truck’s tiller arm.

Controls on these trucks include:

- Lift/lower hydraulic functions

- Accelerator

- Emergency stop button

Controls on a light-duty stacker forklift Controls on an electric pallet jack

Understanding Your Forklift’s Controls

Whichever type of forklift you operate, you must know how the controls work.

Why?

Not only is it important for safety, but OSHA requires it as well.

If you’re unfamiliar with new control types, you can check your equipment’s owner’s manual to find the location of each control and how they work.

Check your owner’s manual for information on your forklift’s control layout

Forklift Controls Explained

You now know the different control layouts of common forklifts.

But let’s go deeper and explain exactly what each control is and how it works.

Steering Wheel

Everyone knows what a steering wheel is.

And with forklifts, it’s pretty much the same as a car.

The only difference is in how they’re positioned on the lift truck.

In sit-down rider forklifts, it’s situated directly in front of the operator:

On stand-up forklifts, it’s located on the left panel and controlled by the operator’s left hand:

Hand-controlled lift trucks do not have a steering wheel.

Instead, they rely on the tiller arm for steering.

Ignition

Like steering wheels, ignitions are self-explanatory.

That said, you might be wondering: How do you turn on a sit-down forklift?

Answer: It’s the same as in a car or truck.

You simply turn the key and the engine starts.

However, there are a couple of things that will prevent you from starting the forklift.

For one, most sit-down trucks have a seat switch that senses if an operator is present and sitting on the seat.

And the lift truck won’t turn on if the switch doesn’t sense the right amount of weight.

Additionally, many lift trucks won’t start if the seat belt is unbuckled.

So if your lift truck won’t start, make sure you’re doing both of these things.

Then try again!

Joysticks

Joysticks are found in stand-up forklifts, like counterbalanced trucks, reach trucks, and order pickers.

The joystick in these trucks houses all the forklift hydraulic controls. (We’ll cover what those are in a later section).

In addition, they are used to drive the fork truck forward and backward and sound the horn.

So, operators can use a single joystick to control all truck functions with a single hand.

Pedals

How many pedals does a forklift have?

Answer: It depends on the type of forklift you’re operating.

Now, hand-controlled lift trucks do not have foot pedals since the operator doesn’t stand on them.

But the other types of forklifts do.

Here are the different pedal configurations based on forklift type:

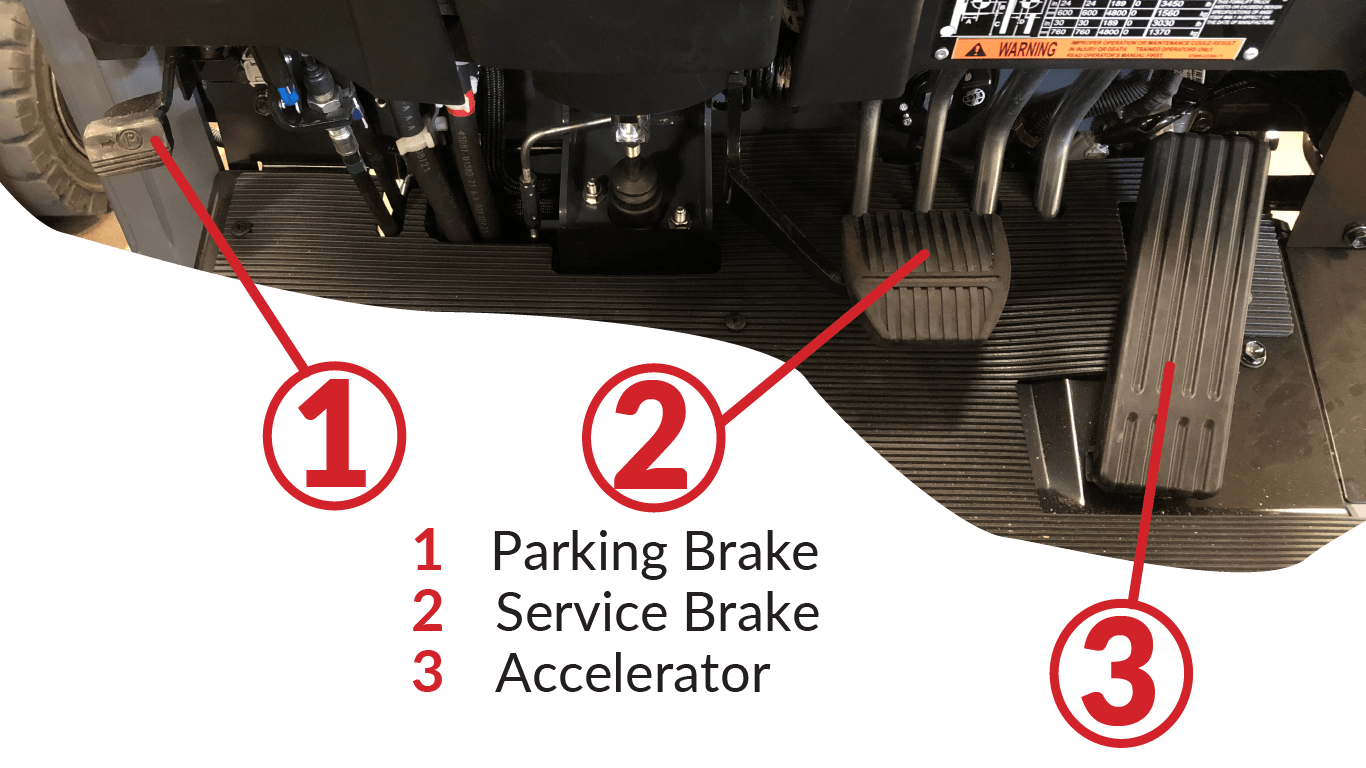

Electric Sit-Down Rider Forklift Pedals

These trucks can have either two or three-foot pedals.

They are the:

- Accelerator

- Service brake

- Parking brake

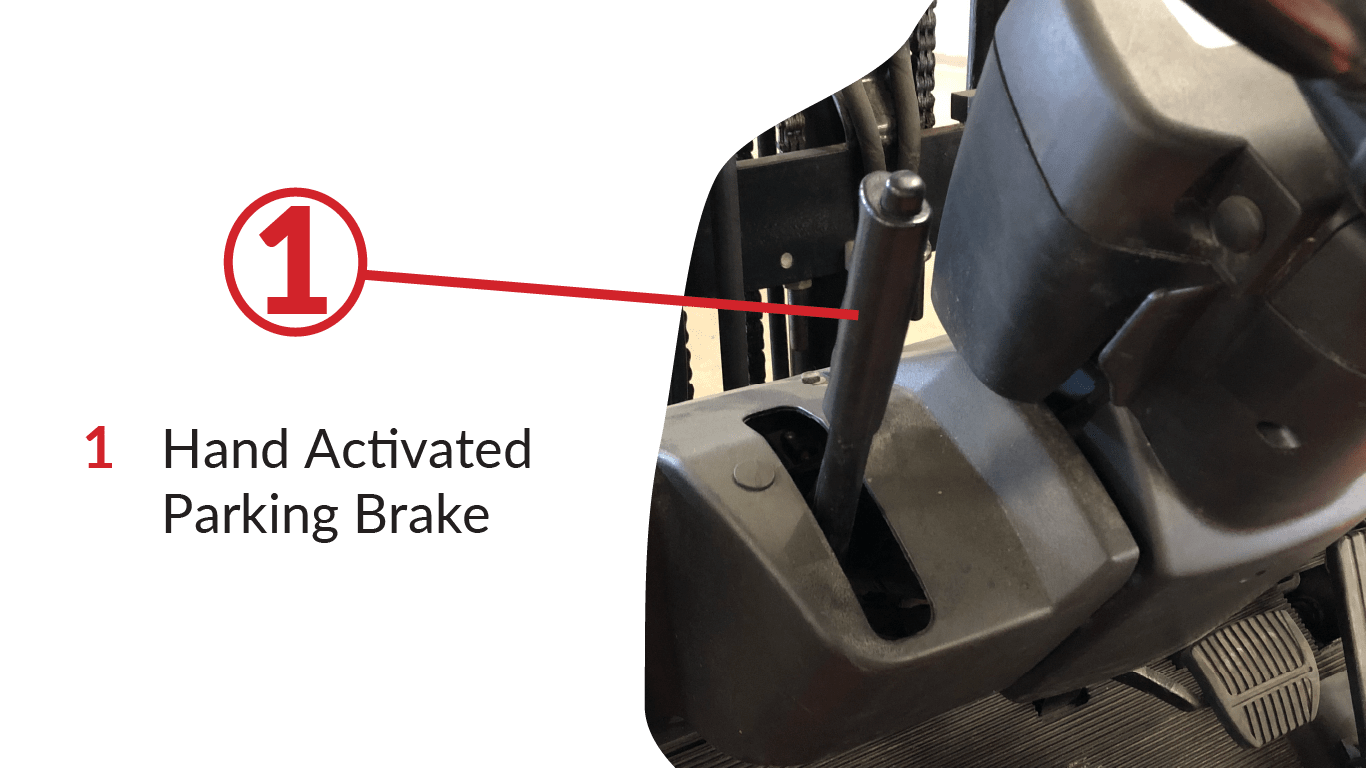

Some models have hand-controlled parking brake levers which are located on the cowl, next to the steering column:

If that’s the case, the lift truck will only have 2 pedals: The accelerator and the service brake.

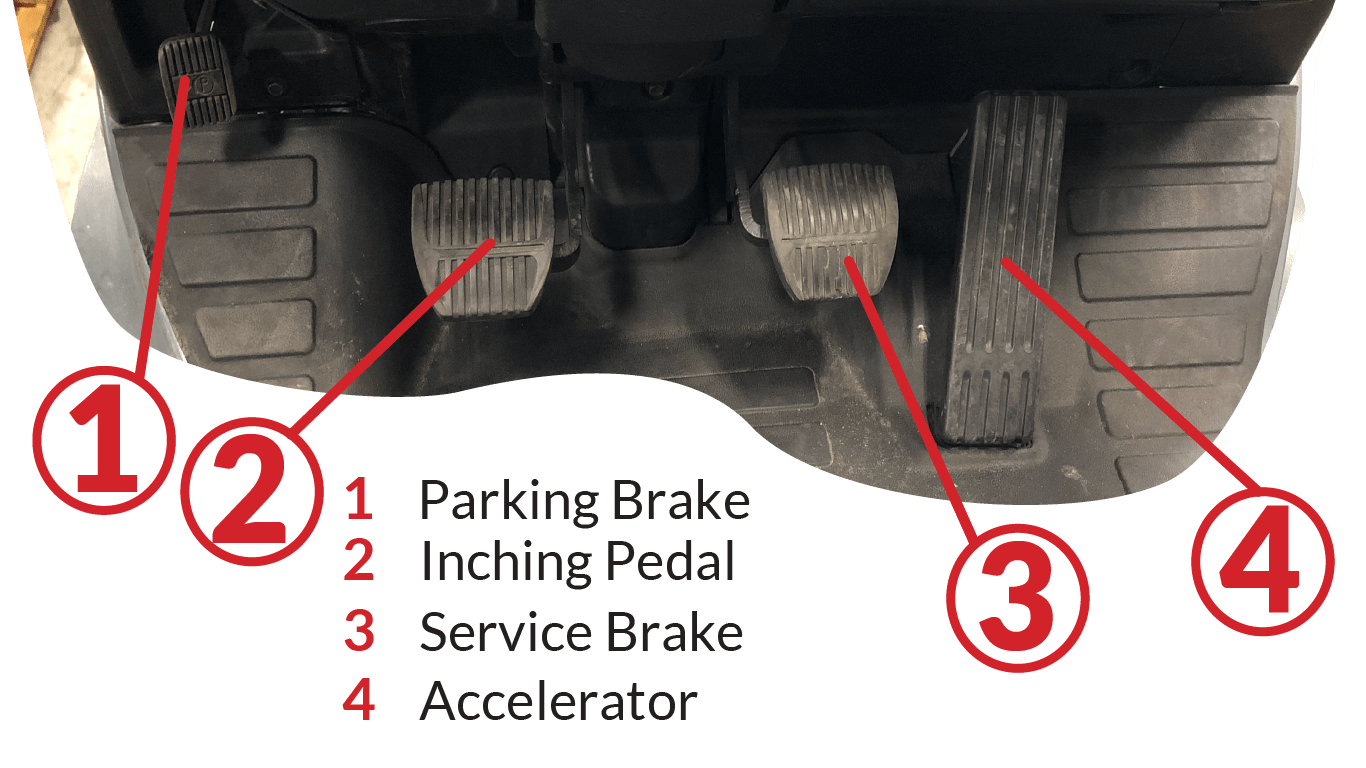

Internal Combustion Sit-Down Rider Forklift Pedals

These lift trucks can have 3 or 4 pedals.

They are:

- Accelerator

- Service brake

- Inching pedal

- Parking brake

Just like electric sit-down riders, the parking brake pedal may not be present.

Instead, the truck will have a hand-operated parking brake.

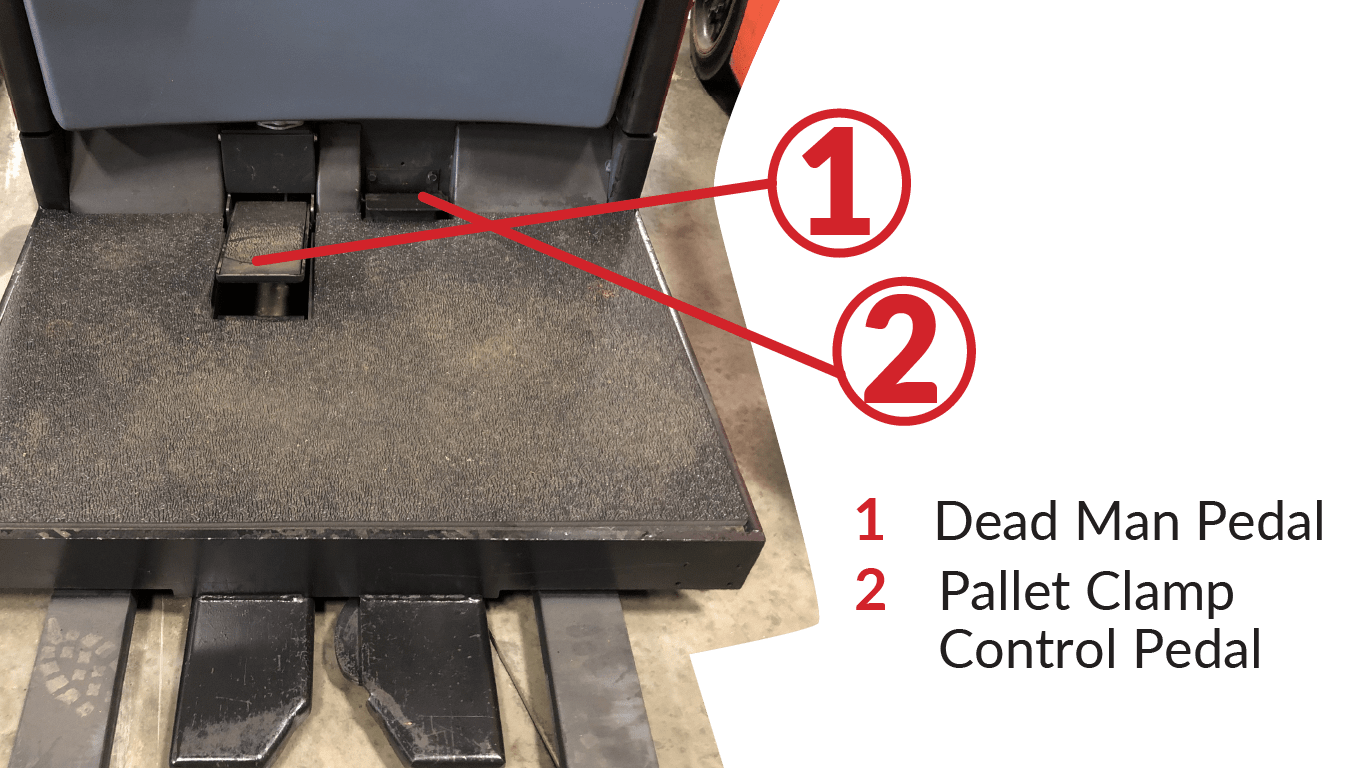

Stand-Up Forklift Pedals

These lift trucks have either 1 or 2-foot pedals, depending on the type of stand-up truck.

For stand-up counterbalanced lift trucks and reach trucks, the only pedal is the dead man pedal.

For order pickers, the pedals include:

- Deadman pedal

- Pallet clamp control pedal

What Does Each Pedal Do?

You’re likely familiar with some of the above pedals, such as the accelerator, service brake, and parking brake.

After all, these pedals are common to road cars and trucks.

But there are a couple of pedals you may not be familiar with.

So, let’s explain those.

Inching Pedal

What is an inching pedal used for?

Its job is to disengage the transmission.

In that way, it’s a forklift clutch.

But why is this useful?

Because it allows you to direct power from the engine away from the driveshaft and to the hydraulic pump without shifting into neutral.

With the inching pedal pressed down, you can use the accelerator to control how fast or slow to raise the load.

This is helpful when lifting heavy loads.

Are Forklifts Automatic?

In years past, forklifts often had manual transmissions with a gear shifter and clutch. But nowadays – just like road cars – most forklifts are automatic.

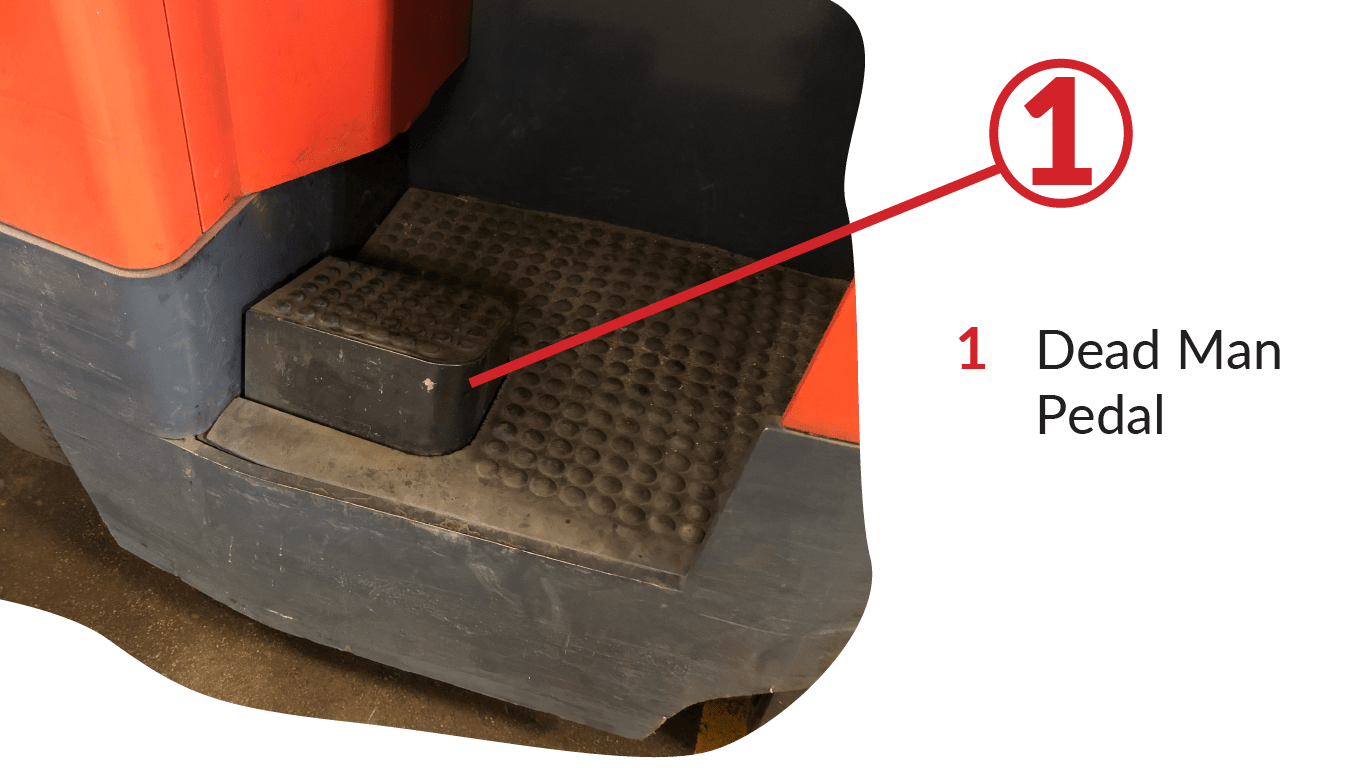

Dead Man Pedal

Also called a “dead man’s switch,” this pedal is a safety feature found in stand-up forklifts like reach trucks and order pickers.

What does this pedal do?

It shuts down the forklift if the operator leaves the operator compartment.

Watch this clip to see how a dead man pedal works:

How it works is simple:

- The operator enters the operator compartment

- They depress the dead man’s pedal

- They turn the lift truck on

- And any time the operator takes pressure off the pedal, the truck shuts down

That way, the truck can’t continue to operate if the operator is not in full control.

Pallet Clamp Pedal

Found on order pickers, this pedal is designed to clamp onto the vertical stud in the center of a pallet.

Watch this clip to see how a pallet clamp pedal works:

Why?

Because doing so stabilizes the pallet and prevents it from falling off the forks.

Forklift Control Levers

Other names for these levers are “hydraulic lift knobs” or “forklift hydraulic controls.”

Each lever connects to the hydraulic control valve and serves to operate the mast and attachment functions.

Depending on the type of lift truck, the control levers can be a little different.

Let’s cover those differences.

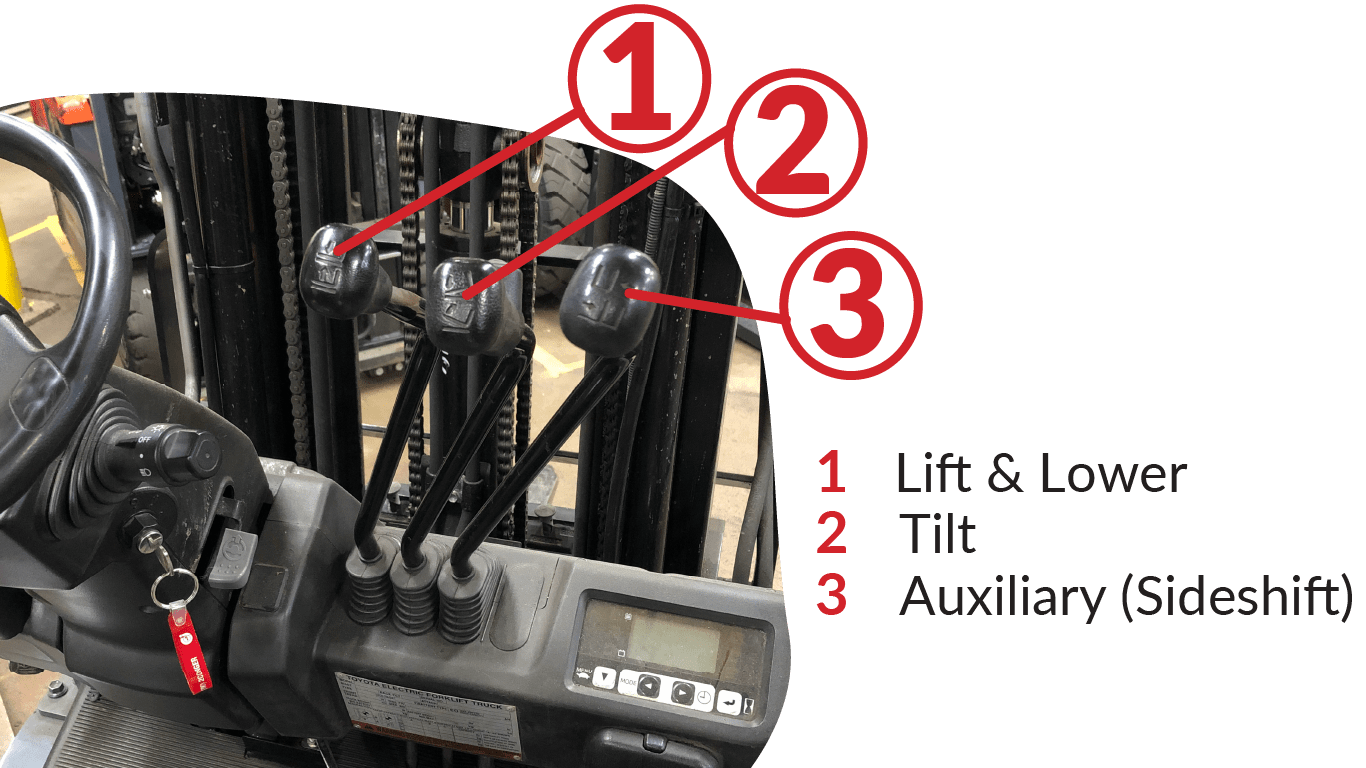

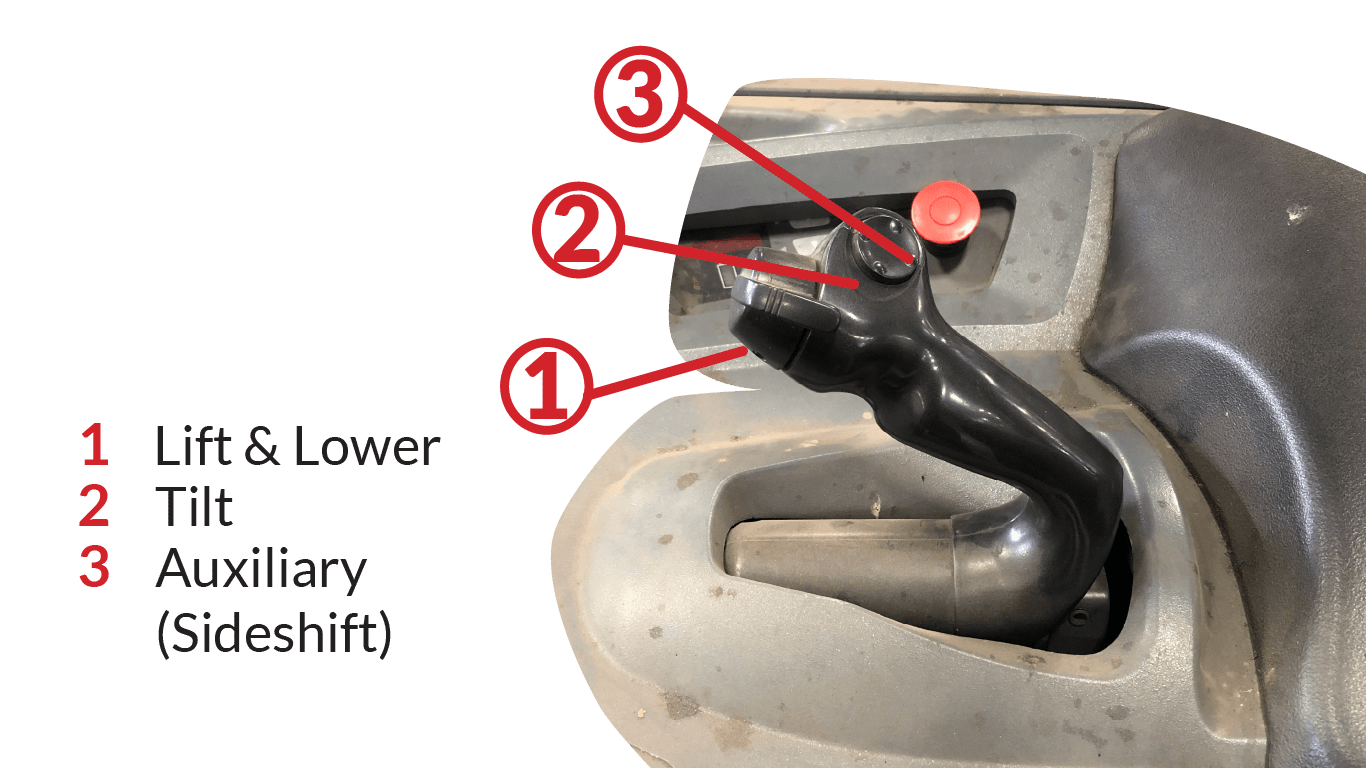

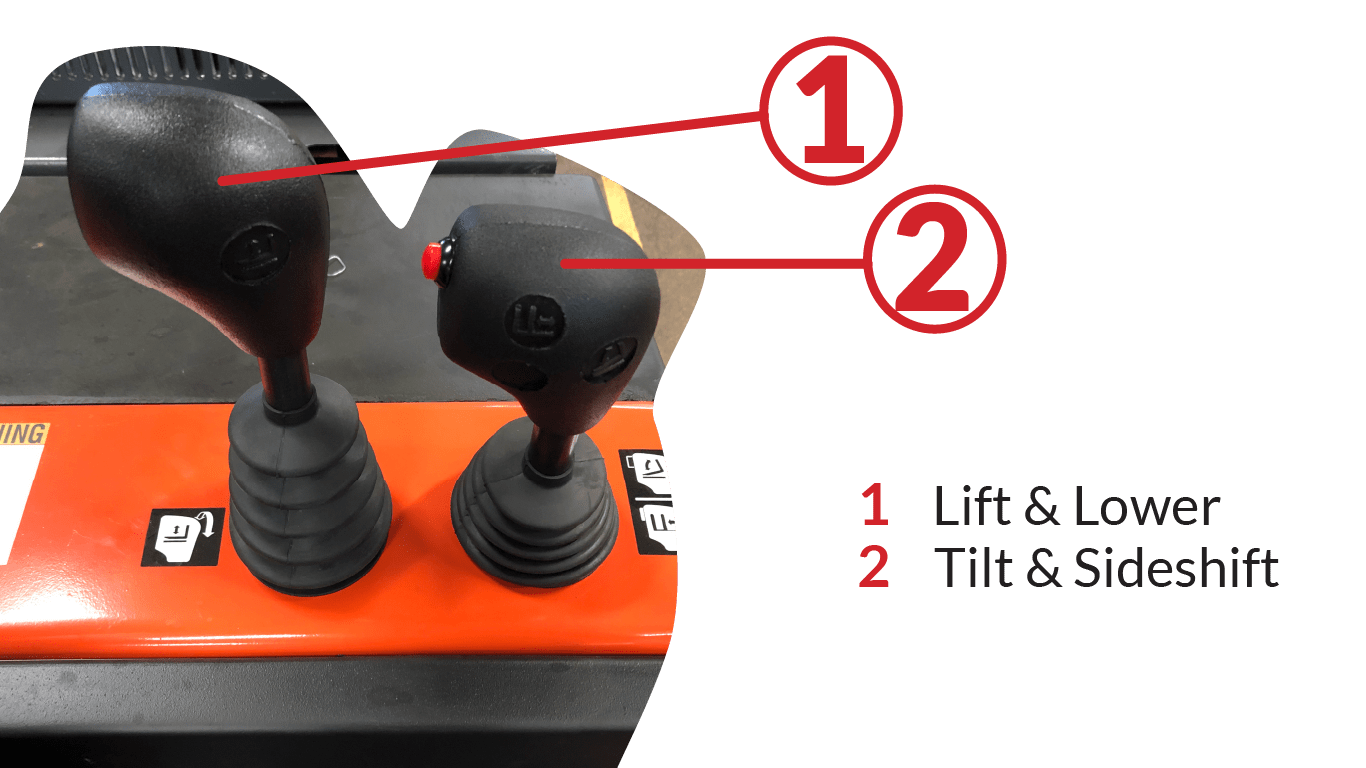

Sit-Down Rider Control Levers

For sit-down rider forklifts, these levers can be in two styles.

One is the traditional lever style:

The other is a mini-lever or finger-controlled style:

Regardless of lever style, sit-down rider forklifts typically have three basic hydraulic control levers.

So what are the 3 levers on a forklift?

From left to right as you sit on the seat, they are:

- Lift and lower

- Tilt

- Auxiliary (usually side shift)

Knowing that you’ll have a good clue as to what the forklift levers do.

- The lift and lower lever are used to raise or lower the forks/attachment.

- The tilt lever moves the mast forward or backward.

- The auxiliary function controls the attachment, which is commonly a sideshifter

Watch this clip to see each forklift hydraulic lever in action:

While 3 levers are typical, sit-down forklifts can have up to 5 forklift control knobs.

What do the extra 2 controls do?

They are clamp forklift controls used for additional attachment functions.

For example, some paper roll clamp attachments can:

- Open and close

- Rotate

- Swing

So to operate each function, you’d need a total of 5 hydraulic levers.

That is:

- One to lift and lower the mast

- One to tilt the mast

- One to open and close the clamp

- One to rotate the clamp

- One to swing the clamp

Watch this clip to see how a paper roll clamp forklift works:

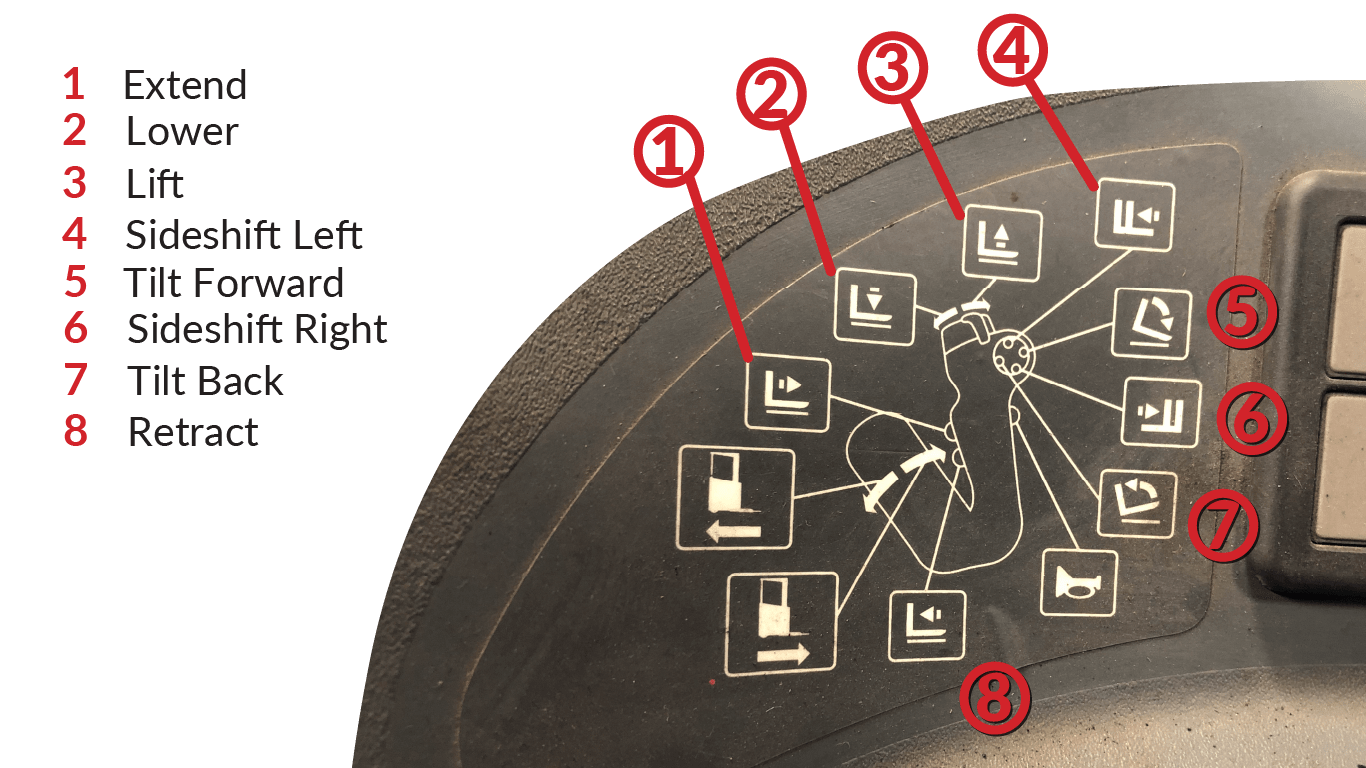

Stand-Up Control Levers

Stand-up forklift hydraulic functions are integrated into the joystick as buttons, instead of being actual “levers.”

Stand-up counterbalanced lift trucks and reach trucks can have 3 or 4 hydraulic controls:

- Lift and lower

- Tilt

- 1 or 2 auxiliary functions

On the other hand, reach truck controls include:

- Lift and lower

- Tilt

- Extend and retract

- Auxiliary function

The extension and retraction functions allow for the truck to perform its namesake “reach” ability:

Watch this clip to see how a reach forklift works:

That is, they allow the operator to extend the carriage forward to retrieve the product, then retract to bring it closer to the lift truck.

Finally, order pickers only have one hydraulic lever: To raise and lower the platform.

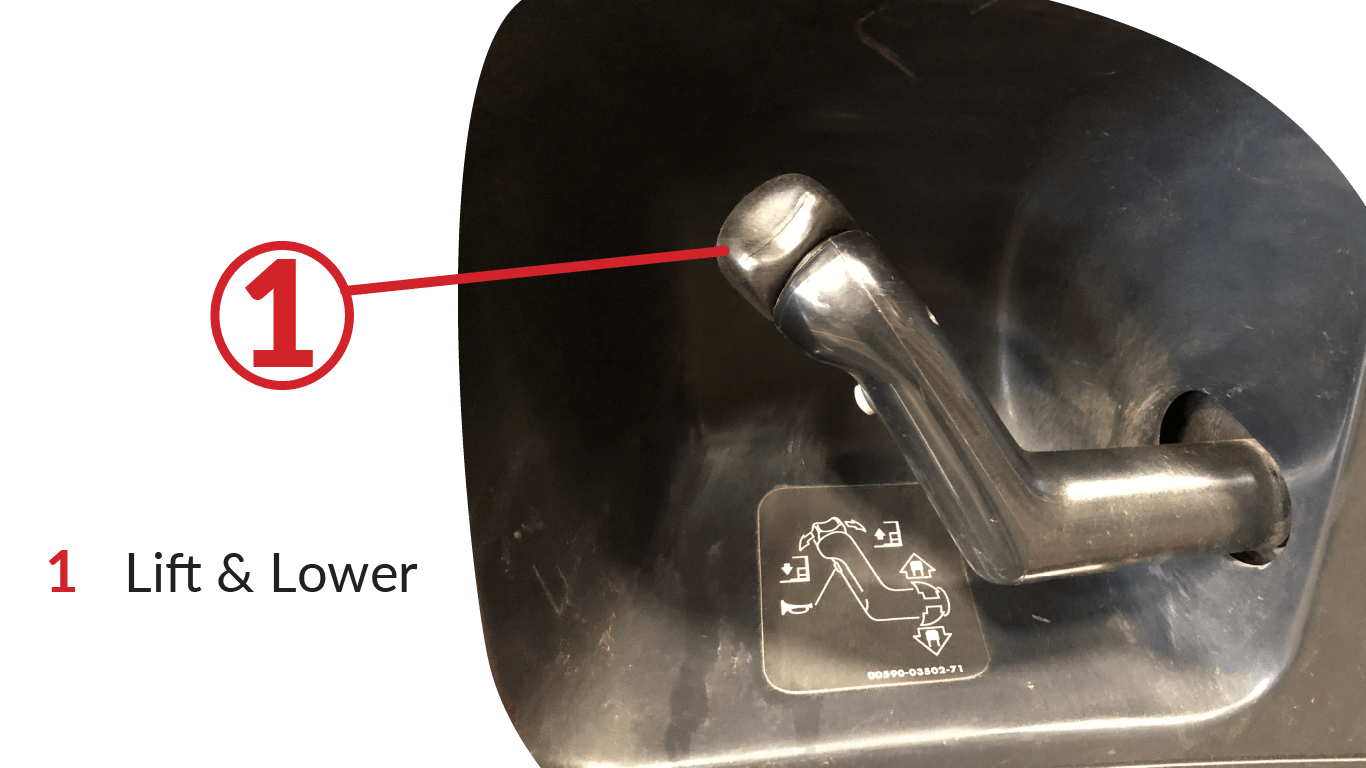

Hand-Controlled Control Levers

Like order pickers, electric pallet jacks have a single hydraulic function, which is used to raise and lower the platform.

This control is integrated into the tiller head instead of being an actual lever.

Stacker forklifts, conversely, can have 1 to 3 functions.

These can include:

- Raise and lower

- Tilt

- Side shift

In these types of trucks, the controls can either be integrated into the tiller head control:

Or, they can be mounted on the frame of the forklift:

Directional Controls

A forklift’s directional controls are simply the gear selector, just as you’d find on a road vehicle.

Forklift directional controls have 3 positions:

- Forward

- Neutral

- Reverse

However, depending on the type of forklift, the directional controls can be in different locations.

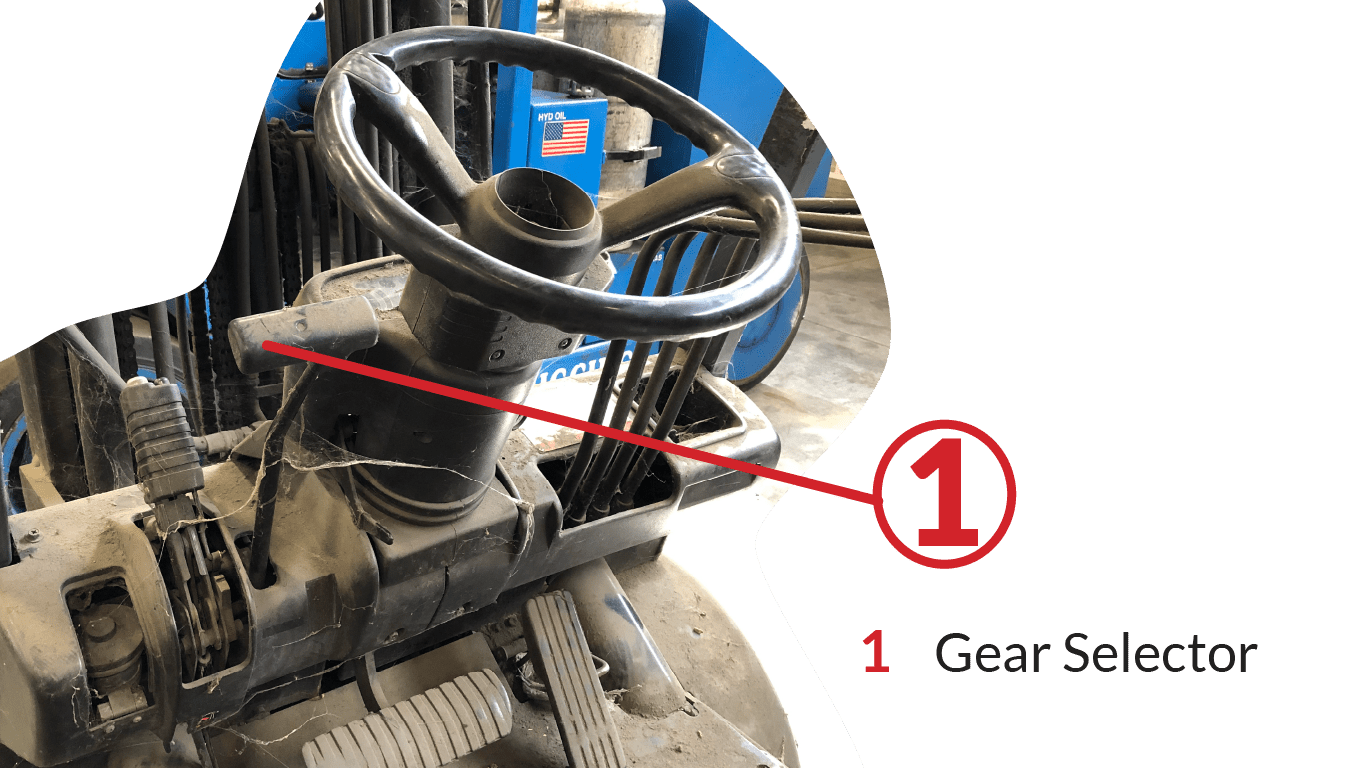

Sit-Down Rider Directional Controls

These trucks can have their directional controls located in 3 ways:

- Mounted on the steering column

- Next to the hydraulic controls

- Foot-operated

Older sit-down forklifts often had the directional control lever located between the steering column and hydraulic control levers.

Newer lift trucks have column-mounted directional controls, located on the left side.

Additionally, some lift trucks feature a single-foot pedal that combines the accelerator and brake with the gear selector.

This configuration is called an “EZ Pedal” or “Monotrol.”

To move forward, the operator simply presses down on the “forward” side pedal.

To brake or reverse, the operator presses down on the “reverse” side.

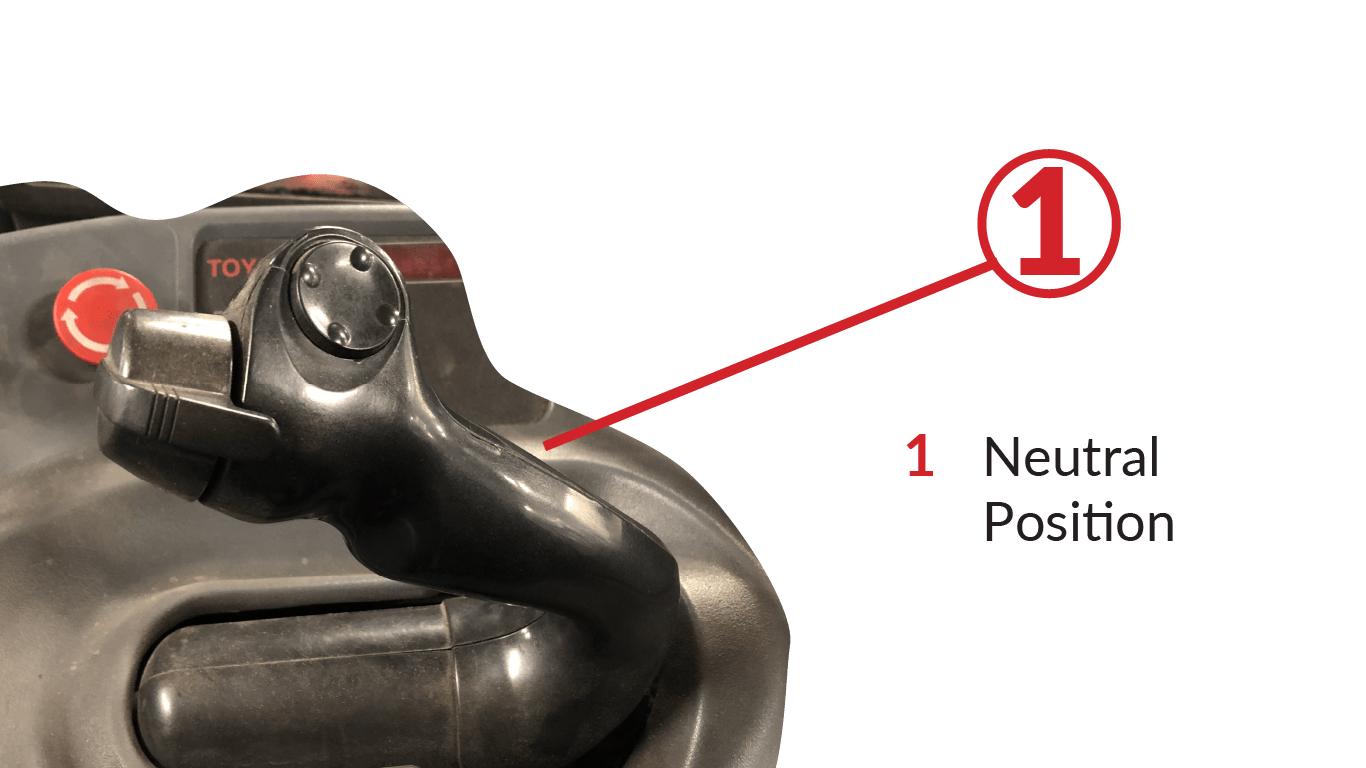

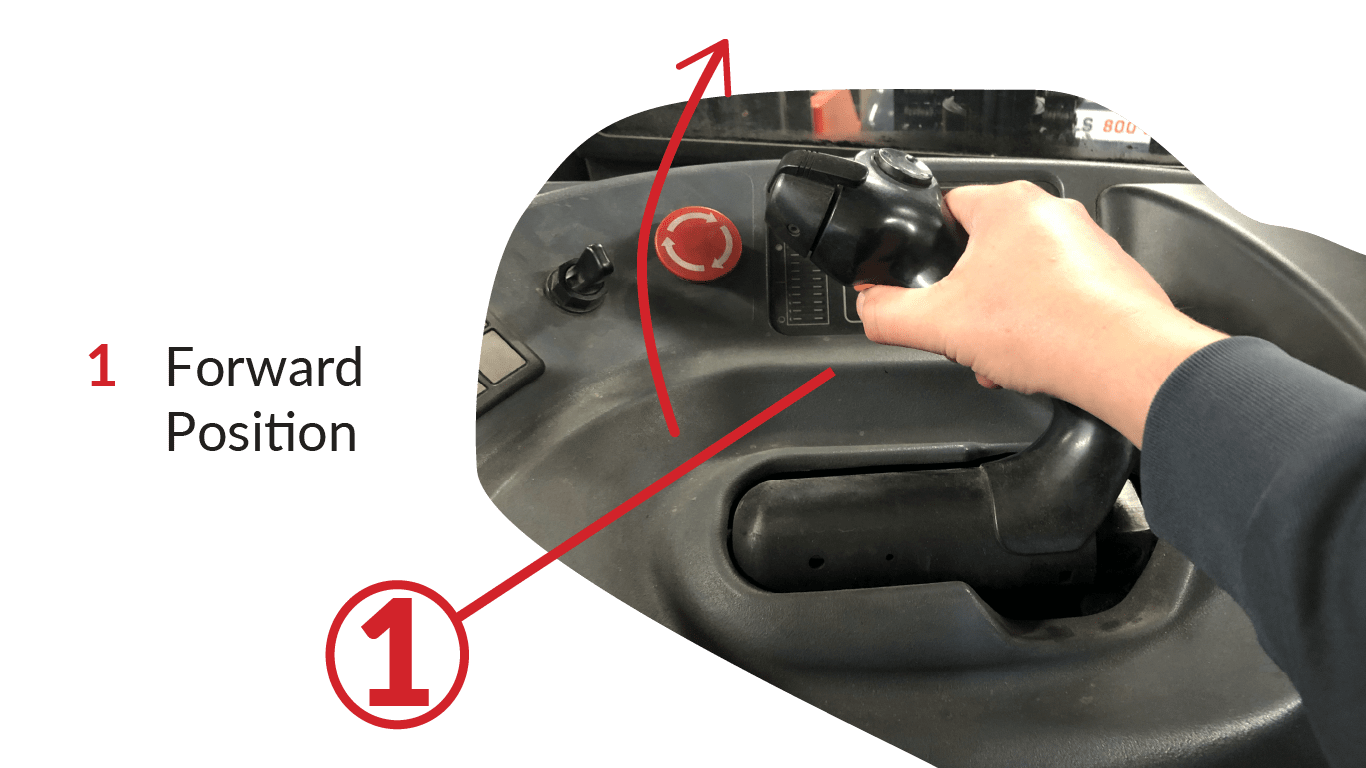

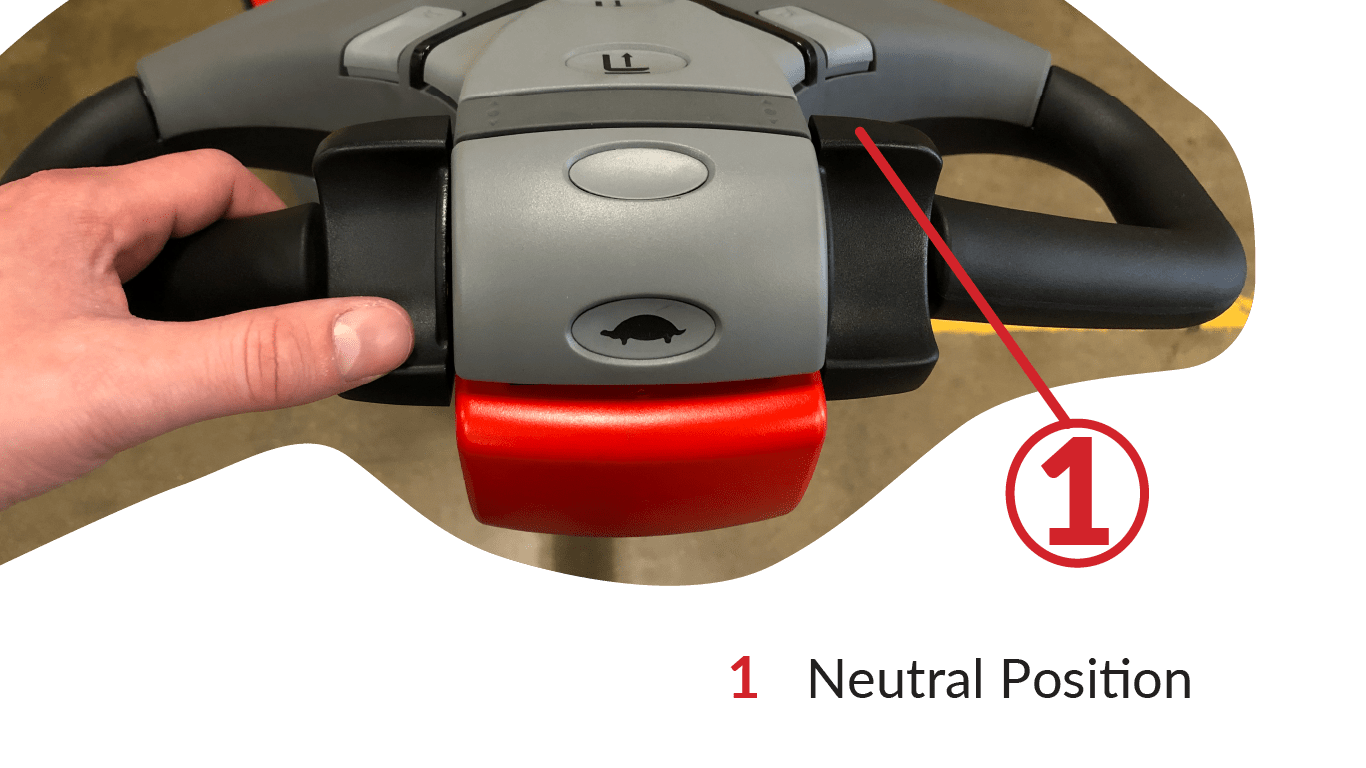

Stand-Up Directional Controls

These trucks have their directional controls integrated with the joystick.

The default position is neutral.

Forward position on a reach truck

To move forward or backward, the operator simply moves the joystick in either direction.

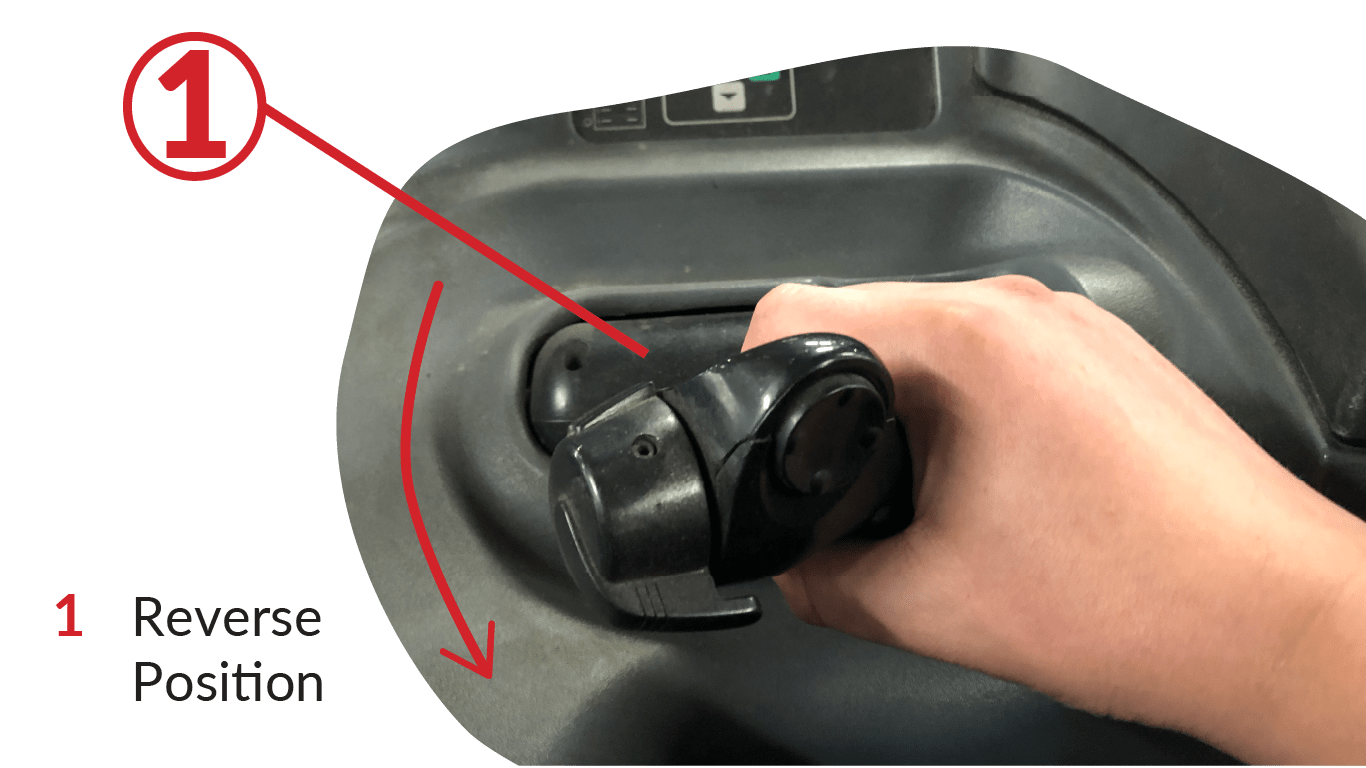

Hand-Controlled Forklift Directional Controls

These trucks’ directional controls integrated into the tiller head.

Most styles feature a twist-type control, much like a motorcycle has.

To move the truck forward or backward, the operator simply twists the handle in that direction.

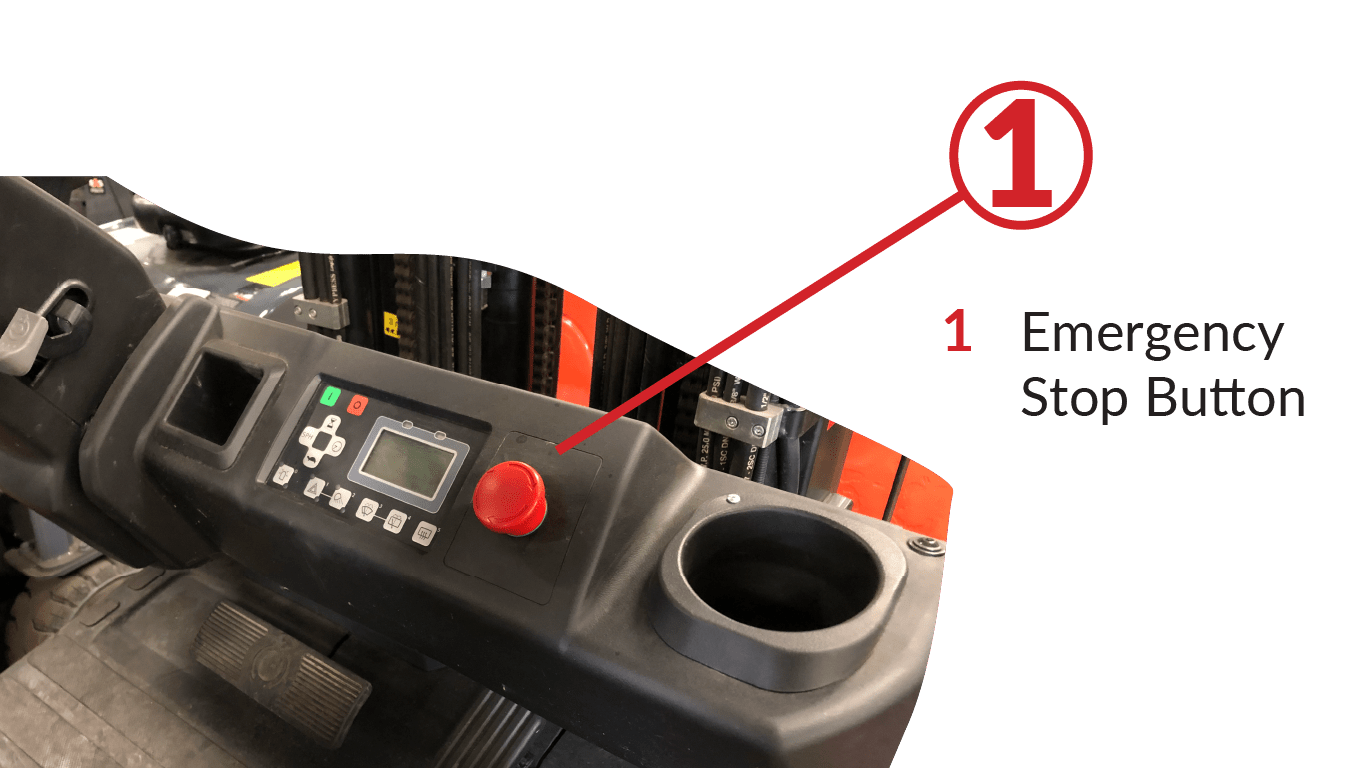

Emergency Stop Button

Some sit-down rider forklifts have an emergency stop button.

What does this button do?

It shuts off all power in the forklift.

This renders the truck unusable until it’s released and restarted.

Hand-controlled trucks have a “belly bumper,” which is similar to an emergency stop button.

The belly bumper works by launching the truck forward and away from the operator if the operator makes contact with it.

Watch this clip to see how a belly bumper button works:

Forklift Instrument Panels

Besides controls, forklift control panels also have various gauges and instruments.

These can include:

- Warning lights

- Engine temperature gauge

- Low fuel indicator

- Battery charge indicator

- Speedometer

- Service hours

- Diagnostic services

These instruments serve the same function as road vehicles.

That is, they alert you to important information about the functioning of the vehicle.

Conclusion

That’s it: All you need to know about forklift controls.