Want to know more about forklift classes?

You’re in the right place.

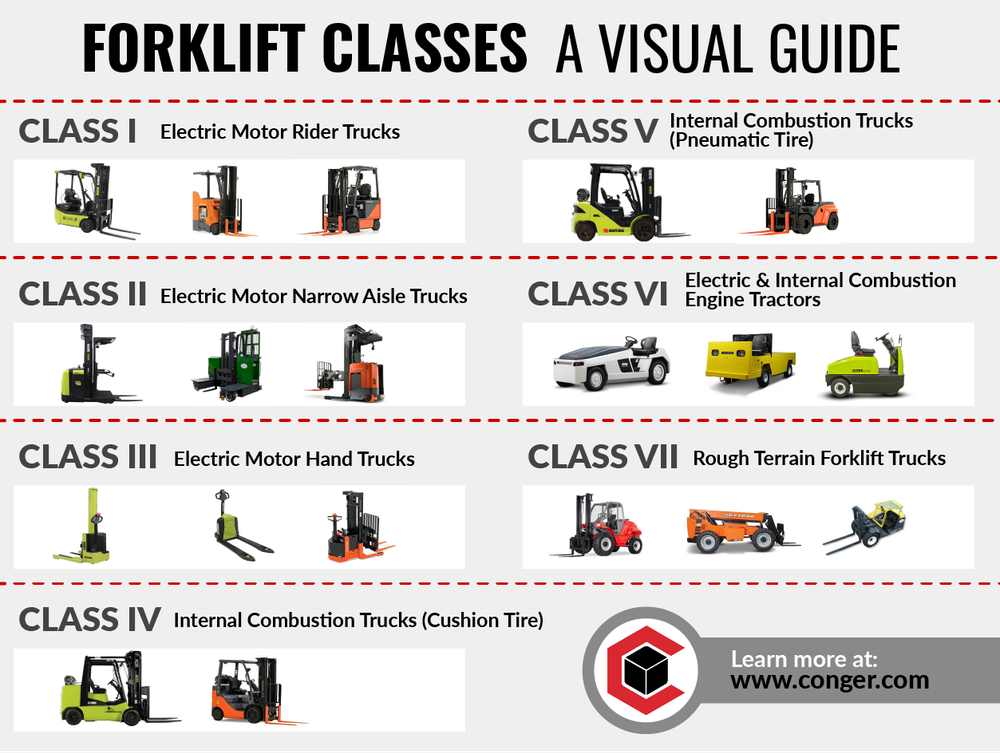

Because we’ve put together the complete guide to forklift classes. You’ll learn:

- What the 7 forklift classes are

- The key characteristics of each

- The features, advantages, and benefits of each

- What applications each class is best for

- Answers to common forklift class questions

Let’s dive in!

Forklift Classes: A Complete Overview

Class I: Electric Motor Rider Trucks

Overview

Class I forklifts are electric-powered motor riders and can be either stand-on or sit-down trucks and they can have either 3 or 4 wheels.

Electric motor rider forklifts have a heavy battery that both powers the truck and also acts as a counterweight to help maintain lifting capacity. That’s why they’re called “counterbalance” forklifts.

They’re versatile and can have either cushion (solid) or pneumatic tires. Pneumatic-tire forklifts are well-suited for outdoor settings. Whereas, cushion-tire lift trucks work best on even indoor surfaces.

Features & Benefits

- Reduced fuel costs compared to internal combustion models

- Excellent for indoor applications

- Quieter and fewer vibrations for better ergonomics

- Low maintenance costs due to fewer moving parts

- Applicable in places with strict air quality standards

- A wide variety of sizes for different applications

Applications

Class I forklift types are ideal for indoor use, especially where air quality is a concern. The following applications can be a good fit for Class I forklifts:

- General warehousing

- Cold storage warehouses

- Food, beverage, and grocery

- Medical/pharmaceuticals

Types

- 3-wheel

- 4-wheel

- Stand-up rider

Learn More

- Toyota Core Electric Forklift

- Toyota Stand-Up Electric Forklift

- CLARK 3-Wheel Electric Forklift

- CLARK 80-Volt Electric Pneumatic Forklift

Class II: Electric Motor Narrow Aisle Trucks

Overview

Class II forklifts are electric-powered motor narrow aisle forklift trucks designed to operate in tight and narrow spaces.

Class II forklifts are used indoors as side loaders or pickers to pick up, move, and deliver materials.

Some Class II forklifts may even have double-deep reach capabilities, allowing them to pick pallets from the second position in pallet racking.

Features & Benefits

- Electric motor/battery-powered

- Have solid tires (often cushion or polyurethane)

- Are designed primarily for indoor-use

- Have lower lift capacities (mostly 3,500 lbs. to 5,500 lbs.) due to their extreme lift heights

- Highly maneuverable, allowing them to operate in tight spaces and narrow aisles

- Can reach high shelves to load and unload pallets – some models can reach 40 feet

- Provide the chance to increase vertical racking space without expanding the warehouse

Applications

- General and specialty warehousing (e.g., high-volume/high-density warehouses)

- Manufacturing

- Retail

Types

There are many Class II forklift models, each with unique features. Additionally, Class II forklifts often have specialized masts or attachments to enhance their productivity and support their operations. Some models include:

- Order pickers

- Turret trucks

- Reach trucks

- Low-lift pallet jacks

- Low-lift platform trucks

- Pivoting-mast forklifts

- Side loaders

- Articulated narrow aisle forklifts

Learn More

- Combilift STE Sideloader

- Toyota Core Electric Turret Forklift

- Toyota Reach Truck

- CLARK OSX Order Picker

Class III: Electric Motor Hand Trucks or Hand/Rider Trucks

Overview

All Class III forklifts use a hand-controlled lever for steering and acceleration. In addition, Class III forklifts can be strictly walk-behind (“walkie”) models or they can be combination walk-ride models.

They’re the perfect solution for loading and unloading trailers and moving loads to staging areas. And they’re great for moving loads over short distances in narrow aisles.

Features & Benefits

- Electric/battery-powered

- Predominantly operate indoors

- Wide variety of models (walk-behind, ride-on) for greater ergonomic accommodations

- Ideal for transporting palletized loads over long distances and for stacking light loads

Applications

Class III forklifts are ideal for the following applications:

- Retail

- General warehousing

- Food and beverage

Types

There are 3 main categories of Class III forklifts:

- Stackers

- Pallet trucks

- Tow tractors

These examples can be different in shape, capacity, size, or functionality based on the manufacturer.

Learn More

- Toyota Core Tow Tractor

- CLARK Electric Walkie Pallet Jack

- Toyota Center-Controlled Rider Pallet Jack

- Toyota Walkie Reach Truck

- CLARK Walkie Stacker

- CLARK End-Controlled Rider Pallet Jack

- Toyota Industrial Walkie Stacker

- Combilift CS Stacker

Class IV: Internal Combustion Engine Trucks (Cushion Tires)

Overview

The name sums up what they are: Class IV forklifts are internal combustion counterbalance lift trucks with solid (called “cushion”) tires that run on diesel, gasoline, LP gas, or compressed natural gas engines (CNG).

These are all sit-down forklifts designed for primarily indoor use on smooth, flat surfaces.

Features & Benefits

- Have solid, cushion tires designed for use on smooth, flat floors

- Cushion tires are puncture-proof since they are not air-filled and they can operate in areas with sharp debris

- Are entirely sit-down forklifts

- Are high-capacity forklifts, ranging from 3,000 lbs. to 100,000 lbs. lifting capacity

- Have internal combustion engines that run on various forklift fuel types; diesel fuel, gasoline, LPG, or CNG

Applications

Class IV forklifts are ideally suited for operation in the following areas:

- Factories

- Distribution and logistics

- Retailers

- Warehousing (large warehouse types)

Types

- Toyota paper roll special

- Toyota box car special

Learn More

- Toyota Core Internal Combustion (IC) Cushion Tire Forklift

- Toyota Large Internal Combustion (IC) Cushion Tire Forklift

- CLARK Core Internal Combustion (IC) Cushion Tire Forklift

- CLARK Large Internal Combustion (IC) Cushion Tire Forklift

Class V: Internal Combustion Engine Trucks (Pneumatic Tires)

Overview

Class V forklifts are just like Class IV forklifts, except that they have pneumatic tires instead of cushion tires.

Pneumatic tires are filled with air, like regular car tires. In other cases, they can be filled with foam, in which case they still are referred to as ‘pneumatic’ tires.

The key advantage of pneumatic tires over cushion tires is that they can work in both indoor and outdoor environments.

That said, they are generally used in mostly outdoor operations, like construction sites and lumber yards, and places that require lifting very heavy loads.

Features & Benefits

- Designed primarily for outdoor use but can be applied both indoors and outdoors

- Are entirely sit-down forklifts

- Use internal combustion (IC) engines fueled by LPG, diesel, CNG, or gasoline

- High-capacity forklifts with lifting capacities ranging from 3,000 to 125,000 pounds (or more based on model and manufacturer)

Applications

These forklifts are highly durable and can be used in a variety of settings, such as:

- Lumber yards

- Construction

- Shipyards and marinas

- Farming and agriculture

Types

- High-capacity pneumatic

- Container handlers

- Marina forklifts

Learn More

- CLARK Large Internal Combustion (IC) Pneumatic Tire Forklift

- CLARK Core Internal Combustion (IC) Pneumatic Tire Forklift

- Toyota Large Internal Combustion (IC) Pneumatic Tire Forklift

- Toyota Core Internal Combustion (IC) Pneumatic Tire Forklift

Class VI: Electric and Internal Combustion Engine Tractors

Overview

Class VI trucks are a special type of industrial truck. They are not forklifts but instead are tractors designed for pulling loads.

Ordinarily, Class VI tow tractors are sit-down style. They featured either a battery/motor or internal combustion engine powered by gasoline, LPG, or diesel.

Features & Benefits

- Pulling/tugging capacity of up to 50,000 lbs.

- Quick acceleration and relatively high top speeds

- Typically have an extremely tight turning radius

Applications

Since Class VI industrial trucks are predominantly used for towing loads rather than lifting, they’re well-suited for operations like:

- Airports

- Manufacturing assembly lines

- Large warehouses

Learn More

Class VII: Rough Terrain Forklift Trucks

Overview

Rough terrain forklifts are a generic term to describe heavy-duty forklifts intended for use on unimproved terrains natural or disturbed, such as construction sites.

Most Class VII forklifts are diesel. Additionally, 4-wheel drive is common, though 2-wheel drive models also exist.

Features & Benefits

- Mostly commonly use diesel engines, for greater power and torque

- Come in various drive options (2-wheel or 4-wheel)

- Have large tractor-like tires for better maneuverability on uneven terrain

- Choice of different masts, including vertical and telescoping

Applications

- Construction

- Lumber yards

- Agriculture and farming

Types

There are 3 basic types of rough-terrain forklifts:

- Vertical mast type: uses a straight mast for lifting loads up and down

- Variable reach type: uses a telescoping boom for picking and placing loads at distances and heights in front of the machine (as opposed to strictly up and down as in vertical mast types)

- Truck/trailer mounted: A portable self-propelled rough terrain forklift often transported to the job site. It is used to unload heavy items from the truck/trailer at the job site. Typically have 3 wheels and pneumatic tires

Learn More

Forklift Classifications Chart

This chart breaks down all 7 forklift classes, with descriptions, examples, and applications.

| Forklift Class | Description | Types/Examples | Applications |

|---|---|---|---|

| Class I: Electric Motor Rider Trucks | Battery/electric-powered forklifts designed primarily for indoor use | Stand-up/sit-down counterbalanced, 3-wheel sit-down, 4-wheel sit-down | Loading & unloading tractor-trailers, Handling pallets, Food storage, retail, and factory, General warehousing. |

| Class II: Electric Motor Narrow Aisle Trucks | Smaller lift trucks designed to operate in tight and narrow spaces with increased maneuverability. | Order picker, High-lift straddle, Side loader, Reach truck, Order picker | Large, dense storage warehouses, High-shelf applications, High-volume handling, General warehousing, Retail, factory, and food storage |

| Class III: Electric Motor Hand Trucks | Specialized for transporting palletized loads over short distances. Often hand-controlled machines. | Low-lift platform, Reach-type with outriggers, Single-face pallet | General warehousing, Food and beverage storage industries, Retail and storage |

| Class IV: Internal Combustion Trucks (Cushion Tires) | Used for lifting and transporting loads on flat indoor surfaces with solid cushion tires; a variety of engine/fuel types, including LPG, diesel, and compressed natural gas (CNG) | Sit-down counterbalance | General warehousing, Distribution, Retail, Factories |

| Class V: Internal Combustion Trucks (Pneumatic Tires) | Used for lifting and transporting loads on both outdoor and indoor surfaces | Sit-down counterbalance | General warehousing, Lumberyards, Construction, Other outdoor applications |

| Class VI: Electric and Internal Combustion Engine Tractors | Towing tractors used for tugging/towing loads rather than lifting. | Sit-down rider | Assembly lines, Airports, Large warehouses, Factories |

| Class VII: Rough-Terrain Forklift Trucks | Used for lifting and transporting materials on rough, uneven terrain; generally diesel-powered; oversized, tractor-style tires; 4WD and 2WD options | Vertical mast (tractor-style forklift), Telehandler (telescoping boom forklift), 3-wheel sit-down counterbalance (often made for easy transport via semi trailer) | Construction. Lumber yards, Auto recyclers, Agriculture and farming. |

Common Forklift Classes Questions

Who Came Up With “Forklift Classes”?

The Industrial Truck Association (ITA) developed the forklift class system in the 1960s and it is still in use today. The system has been widely adopted across the industrial lift truck industry since. It helps to provide a simple identification and labeling system for the hundreds of different types of forklifts across manufacturers, regulators, dealerships, and end-users.

How Does OSHA Classify Forklifts?

OSHA uses the 7-member forklift classification system developed by the ITA to classify forklifts. It’s important to note that forklift classes aren’t an OSHA requirement. They’re simply a classification system for forklifts that OSHA adopted after its development by the ITA.

How Many Classes of Forklifts Are There?

There are 7 lift truck classes. Classes vary in terms of their design, fuel sources, intended applications, and other aspects.

What Are the 7 Classes of Forklifts?

The 7 lift truck types are:

- Class I: Electric Motor Rider Trucks

- Class II: Electric Motor Narrow Aisle Trucks

- Class III: Electric Motor Hand Trucks or Hand/Rider Trucks

- Class IV: Internal Combustion Engine Trucks (Cushion Tires)

- Class V: Internal Combustion Engine Trucks (Pneumatic Tires)

- Class VI: Electric and Internal Combustion Engine Tractors

- Class VII: Rough Terrain Forklift Trucks

What Is a Class 1 Forklift?

Class I forklifts are electric/battery-powered trucks operated either from the sitting or standing position. These types of trucks are emission-free and typically used in lighter-duty, indoor environments like warehouses and distribution centers.

What Is a Class 2 Forklift?

Class II forklifts are electric/battery-powered trucks designed for use in narrow aisles. They vary widely in design, from 3-wheel to 4-wheel chassis, and sit-down and stand-up operations. They have solid tires and are used in warehouses with high-density storage.

What Is a Class 3 Forklift?

Class III forklifts are electric/battery-powered industrial trucks that are operated by a hand-manipulated control arm, either from the ground or a rider platform. They’re commonly used indoors in light-duty applications, for tasks like loading/unloading trucks, transporting materials on skids, and stacking pallets. One key advantage of Class III lift trucks is their maneuverability, making them excellent for narrow aisles and tight spaces.

What Is a Class 4 Forklift?

Class IV forklifts are internal combustion engine trucks with cushion tires designed for use on smooth, indoor surfaces. They come in a wide range of weight capacities and are typically used in warehouses, manufacturing, and retail operations.

What Is a Class 5 Forklift?

Class V forklifts are internal combustion engine trucks with pneumatic tires and designed primarily for use outdoors. They are commonly used in lumber yards, construction sites, and agricultural settings.

What Is a Class 6 Forklift?

Class VI trucks are not actually forklifts – instead, they are electric and internal combustion-powered towing tractors. These trucks are designed for moving loads horizontally, and do not feature a lifting mechanism like forklifts do. They are often used in airports, warehouses, and manufacturing facilities.

What Is a Class 7 Forklift?

Class VII forklifts are internal combustion lift trucks designed for use on rough, off-road terrains. They have large air-filled tires, powerful diesel engines, and a variety of lifting mechanisms. You can find them at work in places like construction sites, lumber yards, and agricultural settings.

How Do I Know What Class My Forklift Is?

Begin by identifying the defining characteristics that set each class of forklifts apart, to determine the appropriate class for your own forklift. For example, is it electric or internal combustion? Does it have a hand-controlled tiller arm? Does it have an upright and forks? Then compare what you have against the descriptions for each class in this article.

If you’re having trouble classifying your lift truck, contact your nearest authorized dealership for help.

What Are the Different Classes of Forklift Forks?

While forklift “class” can refer to the ITA classification, it can also refer to the fork carriage class. The carriage is the component that the forks hang on, and the distance between the top and bottom of the carriage specifies the fork class.

There are 5 total forklift fork classes. The smallest is Class 1, which provides up to 2,200 lbs. lifting capacity. The largest is Class 5, which provides up to 24,198 lbs. of lifting capacity. You can read more about forklift fork classes in our Forklift Forks article.

What’s a Tugger?

Tuggers – sometimes called “tow tractors” are industrial trucks designed for pulling instead of lifting (like forklifts). These trucks are typically used in manufacturing and distribution facilities to move carts, dollies, or other equipment around the facility. For example, some companies use them for transporting raw materials or finished products from one end of a facility to the other.

What Is Required for Class 7 Forklift Certification?

Class 7 forklifts are also known as rough terrain forklift trucks and are typically used in outdoor or off-road environments such as construction sites, lumber yards, or agricultural settings.

To obtain certification to operate a Class 7 forklift, the operator must complete specific training and meet general OSHA forklift certification requirements. These standards require that operators be trained on the specific type of forklift they’ll be using, including training specific to Class 7 forklifts.

That means employers must ensure operators are aware of the specific characteristics of class 7 forklifts and possess any/all knowledge needed to safely operate them.

Conclusion

That’s it: Forklift classes explained.

![Forklift Classes: The Complete List [Infographic and Pictures!]](https://www.conger.com/wp-content/uploads/2023/07/forklift-classes-featured-image-conger-industries.png)