In this post, we’re going to show you EXACTLY how to safely change your forklift’s propane tank.

This is the same process we use day in and day out to keep our lift trucks running.

Let’s get to it!

Propane Forklift Safety Tips

Why Propane is Dangerous

Before we get into the process of changing forklift propane tanks, it’s important to address the hazards of working with this fuel.

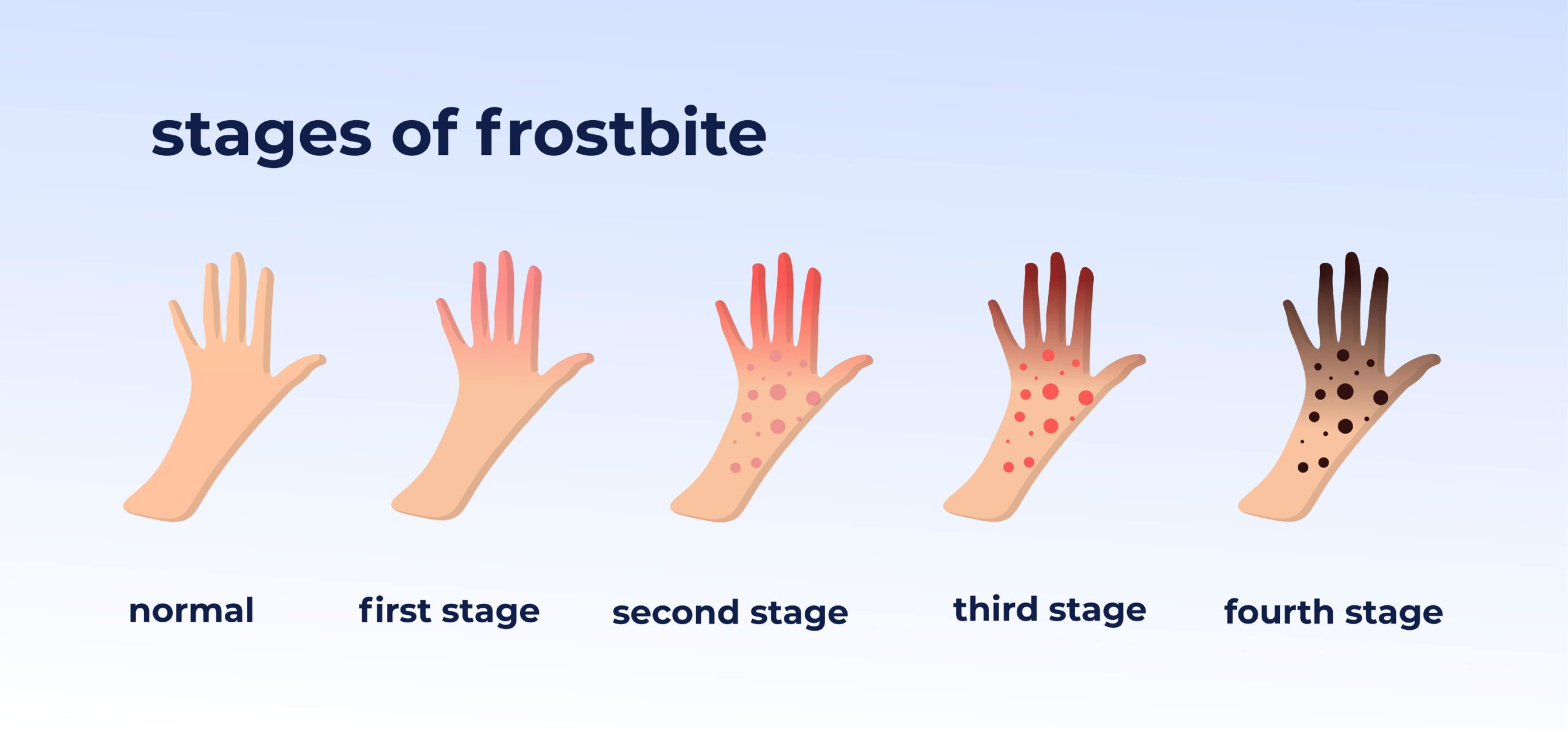

Cold Burns

Propane is kept under super low temperatures of -43.6°F or less.

So any contact with your skin can quickly result in a serious case of frostbite.

Frostbite is most likely to happen when disconnecting and reconnecting a tank to your forklift’s fuel line.

That’s why it’s so important that you wear the proper personal protective equipment (PPE) when doing so.

What Are OSHA’s PPE Requirements for Changing Propane Tanks?

OSHA mandates that employers must provide PPE when they’ve identified hazards that have the potential to injure employees.

But they don’t say exactly what kind of PPE is required.

However, at a minimum, employees should wear impact-resistant, non-vented goggles, neoprene or rubber gloves, a long sleeve shirt, and steel toe boots.

Beyond that, your best resource for selecting the correct PPE is to consult a manufacturer or seller.

If your skin does come in contact with the vapor, you should immerse the affected part in a warm water bath between 104° and 107° F for 15 to 30 minutes.

Then seek medical attention as soon as possible.

Fire & Explosions

Propane – like gasoline – is highly flammable as well as explosive.

Besides that, propane vapor can travel long distances along the ground and accumulate in a “vapor pool.”

In these conditions, an open flame – or even a spark – can easily result in a disaster.

Asphyxiation

There’s one more danger associated with propane: Asphyxiation.

Since propane vapor displaces oxygen, large amounts of it can cause those working in the area to asphyxiate.

That said, asphyxiation by propane is unlikely to occur.

Nevertheless, you should be aware of the symptoms, including:

- Headache

- Dizziness

- Weakness

- Nausea

- Vomiting

- Loss of coordination and judgement

If you or a coworker are experiencing any of these symptoms, leave the area and get medical attention immediately.

Ventilate & Check for Leaks

To minimize these dangers, there are a couple of things you should do when working with propane.

For one, you should only refuel your lift truck outside or in a well-ventilated area inside.

For another, be sure to check for leaks in the tank as well as the forklift’s fuel line during installation.

And, make it a point to schedule regular lift truck maintenance.

That way, any leaks in the exhaust and fuel systems can be caught early and fixed.

How to Change a Forklift Propane Tank (in 10 Steps)

Now you understand the dangers of propane – and what you can do to minimize them.

So let’s go through the process for safely changing a forklift propane tank.

A Quick Word Of Caution

Changing a propane tank can be dangerous if done improperly. Only trained and authorized personnel should change out LP tanks.

This guide is intended only as an informational overview of proper procedures. It is not a replacement for forklift operator safety training.

Prefer video? Just click below to watch the whole process!

1. Put On Your Safety Equipment

As discussed above, this means gloves made of neoprene or rubber, safety glasses, steel toe shoes, and a long-sleeve shirt at a minimum.

2. Secure the Forklift

First, make sure the shift selector is in the “neutral” position.

Second, set the parking brake.

Depending on the manufacturer, your forklift’s parking brake may be foot-operated or hand-operated. And in some cases, the parking brake may be automatically applied when you get off the seat.

Last, make sure that the forks are lowered so they rest completely on the ground.

That way, you won’t run the risk of unsuspecting people bumping into the forks.

3. Evacuate the Fuel Line

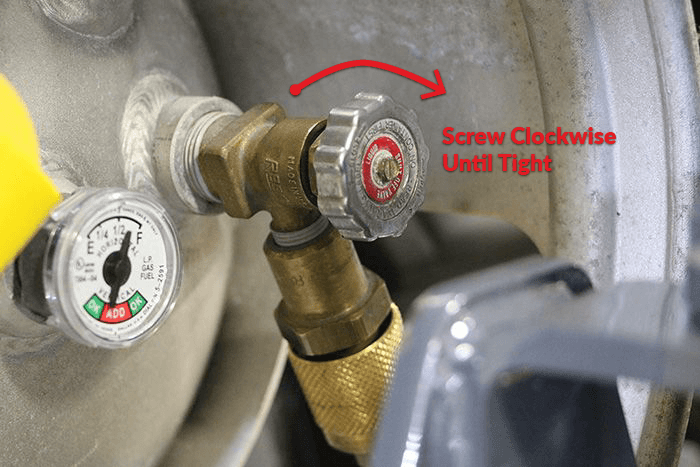

Shut the gas off by turning the tank screw knob clockwise until it’s tight.

Then, turn the forklift on and let it run until it shuts off by itself.

This step removes any extra gas that’s in the line, eliminating the possibility of blowback when you unscrew the LP line coupler from the tank.

Once the forklift has run out of gas, try starting the forklift once more. This step is your double-check to make sure the line is empty.

If it does start, make sure you’ve completely closed the valve. If it doesn’t start, turn the key to the “off” position.

4. Disconnect the LP Fuel Hose

No tools are needed for this step. Simply unscrew it.

5. Remove the Empty LP Tank

The latch holding the tank down may be a bit difficult to undo. So use your body weight if the latch is very tightly secured.

Once unlatched, remove the empty tank. Use two hands here – the tank itself weighs roughly 35 lbs.

6. Install the Full Tank

Lift carefully using proper form, as a full tank can weigh between 40 and 84 lbs.

Then, rotate the tank within the bracket. You want to line the slot in the tank collar up with the screw in the bracket. This will lock the tank into place. When positioned properly, the propane tank pressure relief valve should point upward.

7. Connect the LP Coupler

First, make sure that the valve on the new tank is closed. If you don’t, you could be sprayed with LP when making the connection. So, give the knob a twist clockwise to double-check that it’s tight.

Second, take the fuel line coupler and screw it onto the valve. Turn it clockwise until tight.

8. Secure the Full Tank

Once in place, pull the latch over the tank and secure it. This may be hard. Use your body weight if necessary.

Pro Tip

Some forklifts have an adjustable tank latch. Simply loosen the nut holding the latch, then loosen the latch itself until you’ve got enough slack to secure the tank. Then, tighten the nut and you’re set.

9. Turn the Gas On

Turn the tank screw knob counterclockwise until you can’t anymore. Generally, you’ll hear a soft hissing noise that lasts for one to three seconds while opening the valve. Hearing this will let you know you have proper gas flow.

10. Listen, Smell, and Look for Leaks

If you hear a rushing sound, notice a smell similar to rotten eggs or see white frost, you likely have a leak.

If you do detect a leak, close the valve immediately and ventilate the area to prevent combustion. And make sure to tag out the defective tank.

Pro Tip

You can use a solution of dish soap and water in a spray bottle to inspect your tank or fuel lines for leaks. Just spray the tank or fuel line. The solution will bubble if there’s a leak.

Forklift Propane FAQs

What Are OSHA’s Forklift Propane Tank Storage Requirements?

OSHA has many standards on this topic.

But here’s the gist:

-

Tanks must be protected from damage, heat, and tampering

-

Outlet valves should be closed

-

The amount of gas stored indoors shouldn’t exceed 300 lbs. (unless it’s within a specialized storage area)

-

Tanks can only be stored indoors if it’s not a publicly-accessible building

-

Tanks stored indoors should be kept away from exits, entries, staircases, and walkways

-

Tanks stored outdoors must be kept a safe distance away from buildings and walkways

To review the complete list of rules, check out OSHA’s web page under section 1910.110(f).

Protecting your tanks is a lot easier when you invest in an OSHA-compliant propane storage cage.

Here are a couple websites that sell them:

What is the Lifespan of a Forklift Propane Tank?

According to Propane101.com, tanks must be re-certified 12 years from the date of manufacture.

Then, they must be re-certified every 5 years after that.

Now, there are a few ways to help ensure your propane tanks pass the inspection, including:

-

Ensuring that they’re protected from accidental damage during storage

-

Taking care during transport to avoid denting and damage

-

Keeping them painted and away from water-prone areas to reduce rust

And considering that a single new tank can cost $200 or more, it certainly pays to extend their life as much as possible.

How Do You Exchange Your Forklift Propane Tanks?

If you’re just starting in business, or switching to propane-powered forklifts, you’re probably wondering how to get your tanks refilled on a regular basis.

Local propane vendors, as well as national companies, offer a range of plans to keep you supplied.

And fortunately, it’s pretty simple.

Typically, the company will come to your location and switch out your tanks for new ones.

But many also offer on-site refilling at your location.

That way, you can keep your own tanks.

Regardless of which plan you choose, the company will monitor your usage then schedule refills automatically.

Ferrellgas and AmeriGas are two of the most popular national propane vendors.

But if you prefer to work with a local company, simply google “propane vendors near me” or “propane vendors + your city.”

Where Can You Sell Your Forklift Propane Tanks?

If you’re looking to get rid of your used tanks, your best bet is to contact a propane vendor.

As mentioned, Ferrellgas and AmeriGas are two popular national companies that you can contact.

Otherwise, follow the instructions above to find local vendors.

Now We’d Like To Hear From You

There you have it:

Our 10-step guide on how to safely change a forklift propane tank.

Now we’d like to hear from you…

Which item on this checklist did you not know about before?

What are you going to do differently in your tank-changing process going forward?