Have you ever wondered: “What are order pickers?”

Then you’ve come to the right place.

Because this article explains everything you need to know about order pickers, like:

- What order pickers are

- What they’re used for

- All the types (and subtypes) of order pickers

- Which industries use them?

- Key features, advantages, and benefits of order pickers

- And LOTS more!

Let’s dive in!

What Are Order Pickers?

Here’s a simple order picker definition: Order pickers are material handling equipment used to pick and transport items from shelving or pallet racking to help fill orders in warehouses and distribution centers.

Technically, order pickers are a type of forklift. Within the formal forklift classification system, order pickers are Class II: Electric Motor Narrow Aisle Trucks. Other order picker names include cherry pickers, stock pickers, order selectors, and warehouse selectors.

Order pickers are battery-powered and operated by a person standing on a platform, allowing them to reach shelves to pick items from multiple levels. And lift the platform can reach 20 feet or higher in the air. Also, order pickers can be driven forward, backward, or steered side-to-side.

How Do Order Pickers Work?

Though there are many types of order pickers, the basic principles of operation for many are the same.

Order Picker Power and Drive Systems

Order pickers are electric-powered. So, they’ll have a battery (usually 24- or 36-volt, though some are 48-volt), an electric motor, and various hydraulic pumps.

They usually have 1 centered drive wheel and then a series of non-powered casters behind or in front of the unit. And depending on the model, the electronic control boards (i.e. the “guts” of the electrical system) and the battery are usually at the front.

Order Picker Platforms

Behind that is the operator’s platform, where the operator stands. The platform usually has a metal guard at the top that will accept a harness tie-down for the operator. The platform also contains the order picker controls, often a combination of wheel and joystick.

The operator uses a control panel and/or joystick to move the unit forward, backward, and side-to-side. When the operator reaches the desired location, they use the control panel or joystick to raise or lower the platform and pick up the item by hand.

Order Picker Controls

Operating an order picker is relatively simple:

- Deadman pedal. Each manually operated order picker has a dead man pedal at the bottom that the operator stands on for the order picker to power up. Without depressing the dead man pedal, the order picker should not function.

- Joystick. You use your wrist to push the joystick forward or backward to move the order picker forward or backward.

- Steering wheel. You use the steering wheel to turn the order picker in the direction you want it to go. Some models have a digital direction indicator since you can’t see the tire or easily tell the orientation of the order picker by looking at the steering wheel. This indicator light gives you a visual of your order picker’s trajectory.

- Platform controls. These are the up and down controls located on or near the joystick. Once you’ve come to the spot, you manipulate the controls to raise and lower the platform.

- Pallet claw. Many modern order picker models have a pallet claw – another foot-operated lever – used to grip the pallet stringers. This helps prevent the pallet from falling off the forks.

Can You Drive an Order Picker While It’s Raised?

Depending on the model, the manufacturer may allow movement while the order picker is elevated.

That said, it’s best to minimize driving and turning an order picker while the platform is raised. These movements can introduce instability, potentially resulting in a tip-over. Instead, lower the order picker platform as low to the ground as possible. Then, move into place, and finally raise the platform to your desired height.

Order Picker Batteries

Most order pickers are 24- or 36-volts. Some larger models can also be 48-volt. Common battery models include:

- 12-125-13 (24-volt)

- 12-125-15 (24-volt)

- 18-125-11 (36-volt)

- 18-125-13 (36-volt)

- 18-125-15 (36-volt)

- 18-125-17 (36-volt)

Order picker batteries are usually narrow and tall to fit into the battery compartment.

Many order pickers have a roller system on the bottom. This is so the battery can be loaded via a handling cart, and then simply pushed onto the rollers and slid into place. The battery is then locked into place with heavy-duty metal plates. Once the battery is in place, you plug it into the chassis of the order picker itself with an SB connector.

Order Picker Guidance

There are 3 main types of order picker steering and guidance systems:

Operator-Controlled Guidance

This is the traditional order picker guidance method. It relies on the operator to manually steer the order picker through the warehouse.

The operator typically uses a control panel or joystick to move the unit forward, backward, and side-to-side. This method is typically used in smaller warehouses or where the layout is relatively simple.

The downside of this navigation method can be a higher chance of injury and damage to equipment. Because operators have more freedom, they also have more liberty to run into things, and so on.

Roller Guidance

This method uses sensors, cameras, and other technologies to automatically guide the order picker through the warehouse. It’s often used in larger warehouses or where the layout is more complex.

The order picker follows a predetermined path, and the operator does not need to manually steer the unit. In this way, it’s almost like a train and track system.

The benefits of roller guidance include less equipment damage and less risk of injury (because the operator can’t turn). This can also boost productivity and efficiency in the warehouse.

RFID or Wire Guidance

Order picker wire guidance involves fitting the order picker with a radio frequency identification detector (RFID) and installing a wire buried underneath the floor in the warehouse.

When the order picker drives over the RFID wire, the wire emits a signal that the order picker picks up. The onboard order picker navigation system uses the signals to automatically adjust its route and avoid obstacles and hazards.

This system has all the advantages of the roller guidance system. But without having to modify the order picker (to accommodate the casters). You also don’t have to put bumpers on each side of your warehouse aisles.

But the biggest downsides of wire guidance are the expense and disruption. Installation requires a skilled crew who’ll come to your facility, cut notches in the floor, bury the wire, and seal it with epoxy. However, keep in mind this is a one-time inconvenience and expense (unless you decide to modify the route or add more routes in the future).

Why Use Order Pickers?

If you have a business and deal with many physical items you may benefit from an order picker.

Businesses that use order pickers include warehouses, retailers, distribution centers, fulfillment centers, and the like in order fulfillment applications.

If you have a lot of items stored at different heights, you may use pallet racking, which can go up pretty high. In these cases, it’s not practical, safe, or efficient to have workers moving ladders back and forth, going up and down, and trying to retrieve stock from shelves.

Order pickers provide the following benefits over ladders and other equipment types:

- Efficiency: Order pickers are designed to move quickly and easily through a warehouse, allowing employees to pick items and fill orders more efficiently.

- Ergonomics: Order pickers help reduce the strain and fatigue associated with manual order picking, allowing employees to work longer and more comfortably.

- Reach: Order pickers typically have a vertical reach of several levels, allowing workers to pick items from high shelves and racks without ladders or scaffolding.

- Speed: With the help of order pickers, employees can pick and fill orders at a faster pace than they would be able to do manually. This can be especially useful in high-volume warehouses or during busy periods.

- Safety: Order pickers can help to reduce the risk of injuries associated with manual order picking, such as back strain or falls from heights.

- Navigation: Order pickers can also effectively navigate narrow aisle environments, making them ideal for warehouses looking to maximize space and capacity through closer racking.

Order Pickers and Aisle Widths: What You Need to Know

One of the biggest advantages of order pickers is that they can work in very narrow-aisle applications. (Very narrow aisles measure 6 feet wide or less.)

For example, depending on the features, a Toyota 6-series order picker can be as narrow as 40 inches and as wide as 56 inches. So, if you are looking to add more storage space by reducing your aisles, order pickers may be an excellent option.

You can read more about aisle widths in our calculating minimum aisle widths post.

Order Pickers vs. Other Equipment

Order Pickers vs. Forklifts

Technically, order pickers are a type of forklift. They belong to Class II – Electric Motor Narrow Aisle Trucks. The defining characteristic of order pickers is that they’re electric. On the other hand, forklifts can come in different fuel types, including internal combustion.

Other differences between order pickers and forklifts include:

- Design: Most forklifts are designed for picking up many items via a pallet, forks, and mast. But the operators themselves remain in place. On the other hand, order pickers simultaneously lift the pallet, the platform, and the operator. This makes them useful for hand-picking stock from shelving or racking.

- Mobility: Order pickers are smaller and more maneuverable than many other forklifts, allowing them to move quickly and easily through a warehouse. Forklifts can be larger and many are not designed for narrow aisles or tight spaces.

- Vertical reach: Order pickers are designed to reach higher shelves and racks than most forklifts, with some able to reach 40 feet high. Most forklifts can only reach up to 20 feet.

- Purpose: Order pickers are specifically designed for picking and filling orders, while forklifts are designed for a wide range of material handling tasks. This includes loading and unloading, pallet transport, and stacking.

Order Pickers vs. Reach Trucks

Both order pickers and reach trucks are forklifts (specifically, Class II – Electric Motor Narrow Aisle Trucks). But, while you may see order pickers and reach trucks in the same facility, they fulfill different needs.

A reach truck’s defining feature is its ability to extend its forks forward and backward, something an order picker cannot do

The main difference between an order picker and a reach truck is that with an order picker, the operator and the platform both go up and down. On a reach truck, it’s the mast and the forks that go up and down, as well as in and out. But the operator stays in the compartment – just like a forklift.

Other key differences between the two include:

- Function: Order pickers are more specialized for picking and filling orders, while reach trucks are designed for storing and retrieving heavy loads in high racking. Reach trucks can reach higher heights and carry heavier loads than order pickers.

- Mobility: Order pickers are typically smaller and more maneuverable than reach trucks, allowing them to move quickly and easily through very narrow aisle warehouses. Reach trucks are larger and are not typically designed for narrow aisles or tight spaces.

- Vertical reach: Reach trucks can reach heights of 45 feet, while order pickers can reach up to 40 feet.

- Load capacity: Reach trucks can lift and carry heavier loads than order pickers. Reach trucks can handle loads of up to 4,500 lbs. while order pickers can handle up to 3,000 lbs.

You can learn more about reach trucks in our reach trucks vs. forklifts article.

Order Pickers vs. Cherry Pickers

Some folks refer to order pickers as “cherry pickers.” But a cherry picker can mean a few different things.

It can be a truck with a crane-and-bucket setup mounted to it. These are commonly used, for example, by utility line technicians to reach power lines. It can also be used in agriculture for (as the name says) picking fruits like cherries.

A “cherry picker” can also refer to boom lifts. Boom lifts feature a personnel platform connected to a boom arm and are designed to reach heights usually beyond 30 feet.

Other important differences between order pickers and cherry pickers include:

- Purpose: Cherry pickers are designed for maintenance and repair tasks, such as painting, cleaning, and inspecting high structures. Order pickers are specifically designed for picking and filling orders.

- Mobility: Order pickers are smaller and more maneuverable than cherry pickers, allowing them to move quickly and easily through a warehouse.

- Vertical reach: Both order pickers and cherry pickers can reach high shelves and racks. But cherry pickers can reach even higher heights of up to 50 feet.

- Load capacity: Cherry pickers cannot lift and carry as heavy loads as order pickers (up to 2,000 lbs.) Whereas, order pickers can handle loads of up to 3,000 lbs.

Order Pickers vs. Turret Trucks

Order pickers and turret trucks are remarkably similar. The key difference between them is that a turret truck uses forks to retrieve and place pallets. Again, an order picker relies on the operator (using their arms and legs) to retrieve the stock and then place it at the rear of the order picker. And with an order picker, the platform moves the operator up and down.

Like an order picker, some turret truck models have the operator move up and down with the platform. But unlike in an order picker, the turret truck operator remains seated for the entire time.

Other differences between order pickers and turret trucks include:

- Function: Order pickers are designed for picking and filling orders, while turret trucks are designed for loading and unloading pallets, and other heavy-duty material handling tasks.

- Mobility: Order pickers are smaller and more maneuverable than turret trucks. This allows them to move faster through a warehouse.

- Vertical reach: Both order pickers and turret trucks can reach high shelves and racks, but turret trucks can reach even higher: up to 45 feet against order pickers’ 40 feet.

- Operator position: An order picker operator walks behind or rides on the unit, while a turret truck operator sits in a cab or on a platform. Read here the difference between sit-down forklifts vs. stand-up forklifts.

- Load capacity: Turret trucks can lift and carry heavier loads than order pickers: up to 6,000 lbs. against order pickers’ 3,000 lbs.

- Carriage: Unlike order pickers’ fixed carriage, turret trucks have a rotating carriage, which allows the operator to rotate the forks and pick up the pallet from any angle.

Order Picker Types

There are 2 main categories of order pickers: mid-level and high-level.

This categorization is mainly based on the maximum height they can allow a worker to reach and their load capacity. Mid-level pickers don’t reach as high as high-level pickers.

Additionally, mid-level order pickers are often free-roaming equipment, manually-guided by workers. High-level order pickers are usually wire- or rail-guided. That means they may require a wire guidance system to navigate narrow (or very narrow) aisles.

Based on this broad categorization, the different types of order pickers include:

- Walkie order pickers: This type of order picker is a powered pallet truck where an operator walks behind the unit and picks items from racks or shelves at different levels. It has a narrow aisle width and can reach heights up to 15 feet.

- Rider order pickers: This type of order picker is similar to a walkie order picker, but has a platform for the operator to ride on while picking orders. It can reach heights of up to 40 feet and is ideal for large warehouses with high rack storage.

- Order pickers with work platforms: This type of order picker has a built-in platform for the operator to stand on while picking orders. It can reach heights of up to 25 feet and is ideal for warehouses with high-density storage.

- Stock pickers: This type of order picker is a smaller, portable unit that can be used to pick items from shelves or racks at different levels. It has a vertical reach of up to 30 feet and is ideal for small to medium-sized warehouses. You’ll be most likely to find stock pickers in your local grocery store.

- Vertical order pickers: This type of order picker is a specialized machine that moves vertically to pick items from high shelves or racks. It can reach heights of up to 40 feet and is ideal for warehouses with high-density storage.

- Automated guided vehicle (AGV) order pickers: These automated order pickers are used for retrieving small items. They use automated technology to navigate the warehouse, pick items, and transport them to the packing or shipping area. AGV order pickers are ideal for high-volume warehouses because they can work 24/7. They require no breaks, make no errors, and have no need for supervision.

- Furniture order pickers: For example, Toyota’s furniture order picker can accommodate carts or furniture platforms and lift a wide variety of large or bulky items. (“Electric Order Pickers | Toyota Forklifts”) It has a lifting capacity of up to 1,600 lbs. with up to 366 feet max elevated height.

Order Pickers Features

Many order pickers operate similarly. But they can have differences that affect how they perform and in what environments they perform best. Here are some key features shared by many order pickers:

Order Picker Weight Capacities

Most standard-size order pickers have a maximum load capacity (weight limit) of between 1,500 lbs. and 3,000 lbs.

Check the data tag for the particular load capacity of your order picker. Also, train your workers on weight limits and ensure they will not use the order pickers to grab loads of more than they’re rated for.

Order Picker Heights

Not every order picker will reach the same height.

Mid-level order pickers reach between 15 and 25 feet high, while high-level pickers can reach between 20 and 35 feet high. You need order pickers that can reach the highest shelves in your warehouse. You can find this information on the order picker’s data plate.

Order Picker Accessories

Besides their weight, height, and guidance system, an order picker can have various other accessories or attachments, such as:

- Stationery forks.

- An attached cart.

- A platform or various platforms.

- Auto-locking pallet clamp.

- Load-facing operator controls.

- Automatic steering control (with rail-guided systems).

- Retractable tether.

Order Picker Manufacturers

Here are some top order picker manufacturers. You can find a complete list of forklift manufacturers here.

Toyota Order Pickers

If you’ve ever wondered: Who’s the biggest forklift manufacturer in the world? The answer is Toyota Material Handling. It’s also the #1-selling forklift brand in the United States.

The Columbus, IN-based company produces several order picker models, including the 6-series, 7-series, and 8-series order pickers. Plus, Toyota offers a furniture order picker. Specifications for these models range from:

- 1,600 to 3,000 lbs. Capacity

- Lift heights up to 390 in.

- 24-volt or 36-volt electrical systems

Additionally, models can navigate in aisles as small as 4 ft. wide. Moreover, models can be equipped with rail or wire guidance systems.

CLARK Order Pickers

CLARK Material Handling (based in Kentucky) is a top order picker manufacturer, with over 100 years in forklift manufacturing.

CLARK’s electric order picker models include the OSX15 and the OSQ. The technical specifications for these models range from:

- 600 to 3,000 lbs. capacity

- 24-volt or 36-volt electrical system

- 126 to 366 in. lift height

Additional features on CLARK order picker models include regenerative braking, on-board diagnostics, and AC drive and hydraulic motors.

Raymond Order Pickers

George Raymond Sr created the Raymond Corporation in 1922 in Greene, New York. The company has since established itself as a legendary forklift manufacturer.

Raymond order picker models include series 5300, 5500, 5600, and their furniture order picker. Specs vary between each model, but include:

- 1,500 to 3,000 lbs. capacity

- 241 to 456 in. maximum elevated height

- 24- or 36-volt electrical systems

Linde Order Pickers

Linde Material Handling has been around since 1904 and is now the largest electric forklift manufacturer in Europe and globally.

Linde offers a several platform-style order pickers, with the following technical specs:

- Up to 2,600 lbs. capacity

- Up to 400 in. lift height

- 24- or 48-volt electrical systems

Yale Order Selectors

Hyster-Yale Materials Handling is a combination of Yale Material Handling and Hyster Company. Founded in 1844, Yale is a US company with a global presence in the lift truck industry.

Yale presently offers 4 order selector models with the following technical characteristics:

- Up to 3,000 lbs. capacity

- Up to 360 in. lift height

- 24-volt electrical systems

Crown Order Pickers

Headquartered in New Bremen, Ohio, Crown Equipment Corporation was started in 1945. As of this publishing, Crown is the 5th largest forklift manufacturer in the world.

Crown offers several low- and high-lift order picker models. The specifications for this range are:

- Up to 3,000 lbs. Capacity

- Up to 371 in. lift height (platform, forks can reach up to 366 in.)

- 24- or 36-volt electrical systems

Order Picker Prices: What Can You Expect to Pay?

If you’re shopping for an order picker in 2023, you can expect to pay anywhere from $10,000 to $24,000 or more for a used one. If you’re looking for a new model, expect it to cost anywhere from $28,000 to over $40,000.

Be aware: Order picker prices can vary widely.

Depending on the model, condition (new or used), the features selected, and a whole host of other factors, the specific cost of your chosen order picker can be anywhere in the ranges above. It can also be even higher or lower.

That’s why it’s best to contact your nearest factory-authorized order picker dealer. They can help you determine what you need, based on your specific application, goals, preferences, etc. And that will ensure you get the most accurate pricing.

Order Picker Forklift Training and Certification

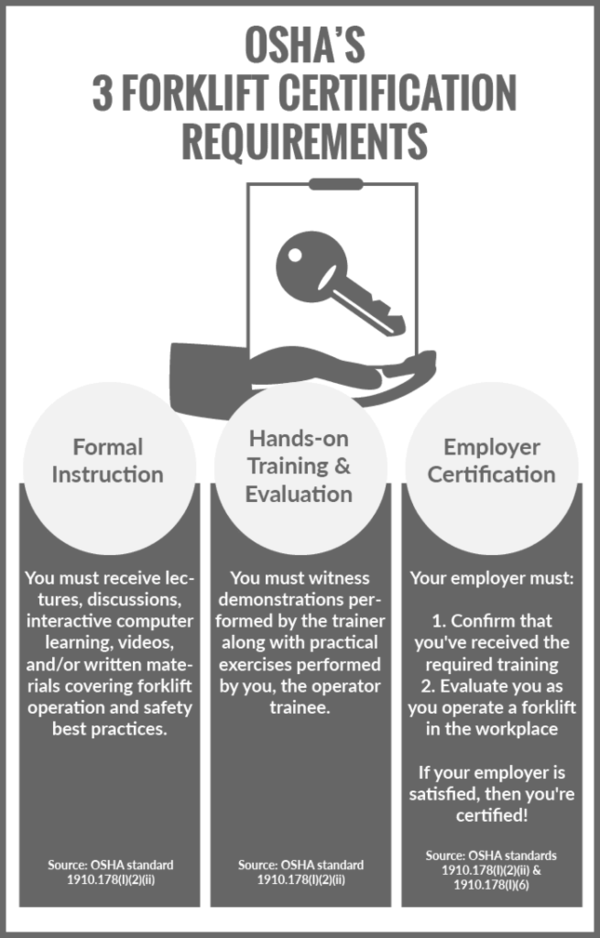

OSHA’s Order Picker Requirements

OSHA is the top workplace watchdog. It sets the rules, regulations, and requirements to maintain workplace safety. This also applies to powered industrial trucks (PITs).

And since order pickers are considered powered industrial trucks (class II), they’re also regulated under OSHA requirements. Thus, organizations that use order pickers must follow OSHA’s rules accordingly.

For an excellent resource on general OSHA order picker rules and regulations, check out Raymond West’s FAQ page.

Do You Need Special Training to Operate an Order Picker?

OSHA requires that to be forklift certified, you have to be certified on the particular type of forklift you will be working on. That means if 2 forklifts are substantially dissimilar, you need to get forklift certification particular to the new lift truck you’re expected to operate.

For example, even if you are certified to operate a sit-down 3-wheel electric forklift, that does not necessarily carry over to an order picker. You would need separate training on order pickers. This is because order pickers are quite different from 3-wheel sit-down electric forklifts.

Learn more about Conger’s Forklift Operator Certification Training.

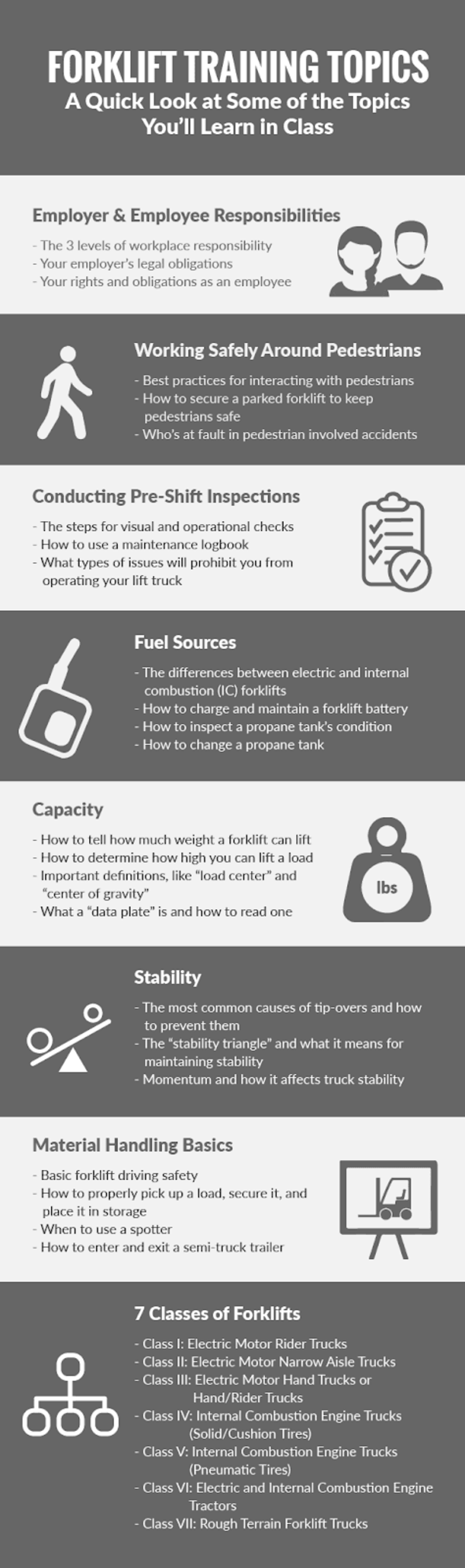

Order Picker Training and Evaluation

To become a certified forklift operator, OSHA requires classroom training and education, skills evaluation, and final approval by the employer that the operator can safely operate in conditions found in the workplace.

OSHA has many classroom requirements. Some topics include:

- Knowledge of safe battery and refueling procedures

- Knowledge of your specific forklift (in this case, order pickers)

- Safety requirements, such as pre-shift inspections

- General principles of safe forklift operation

You can read more about forklift training in our forklift license guide, our write-up on online forklift certification, and our forklift safety training guide.

Order Picker Safety

Order pickers can present special hazards because of their unique design. Thus, it’s essential to understand how they operate and do so cautiously to avoid injuries – or worse.

Here are some general order picker safety tips to keep in mind:

Note: Some of the following tips have been adapted from Toyota’s 6-series order picker operator’s manual.

This list does not constitute an exhaustive list of order picker safety rules. Always refer to your particular machine’s operator manual for specific safety guidelines.

- Only trained and authorized personnel should operate an order picker. Always refer to your particular machine’s operator manual for specific safety guidelines.

- Always wear a compliant safety harness attached to a designed anchor point. Even if you’re driving around for just a short bit, such as moving it for parking. You still must wear a harness.

- Avoid traveling with the platform elevated. Travel with the platform as low to the ground as possible. Never turn (left or right) while the platform is raised. This can cause the order picker to tip over.

- Don’t allow anyone to stand or pass under the raised platform. Be extremely cautious when lowering an order picker. You don’t want to come down on top of somebody, infrastructure, or equipment.

- Identify hazards in your working environment and create a plan for how to avoid them. Don’t drive over bumps, dips, debris, etc.. These can cause instability.

- Keep all body parts within the platform and on the controls while in motion. Don’t place any body parts in the mast.

- Don’t carry passengers.

- Watch for pedestrians. Define traffic lanes and separate pedestrian and equipment traffic.

- Understand your order picker’s capacity. Don’t carry any weight above the maximum capacity.

- Don’t operate without securing the battery with battery gates and blocks (to prevent excessive side-to-side/front-to-back motion)

- Don’t use an order picker to place or remove pallets from racking. When carrying a pallet, secure it in place on the forks using the pallet clamp.

- Don’t operate on slopes or ramps.

- Operate slowly and cautiously, especially when raising/lowering, entering/exiting aisles, at intersections, etc.

- Be aware and watchful of overhead obstructions. Also be mindful of aisle or wall protrusions that could catch you, the order picker, the load, etc.

Order Picker Daily Inspections

Order pickers require an inspection either daily or before each shift (if operating more than 1 shift per day). This inspection is generally 2 parts: visual and operational.

The visual inspection should include (but not necessarily be limited) to:

- Checking the battery and connectors (if using a lead-acid battery, you’ll need to ensure it’s properly cared for)

- Ensuring all guards and covers are in place

- Ensuring proper hydraulic fluid level

- Inspecting the wheels, lift chains, and hoses for damage and/or wear

- Ensuring all warning lights, decals, and documents are present and legible

- Inspecting the harness and tether condition

- Checking for and nothing anything else in general that is unusual

The operational inspection should include (but also not necessarily be limited) to:

- Ensuring proper operation of the lift and lower functions

- Check the effectiveness of the brakes

- Ensuring the deadman pedal operates as it should

- Ensuring the speed control, steering, horn, emergency power button, and all switches and alarms work as intended

Performing the daily inspection is not only an OSHA requirement and general good idea safety-wise. It also helps catch any little issues before they balloon into bigger (and more expensive) issues.

Order Picker Maintenance

Order pickers also require regular maintenance, just like more ordinary electric forklifts.

So, what kind of maintenance do order pickers require?

Forklift technicians generally perform the following tasks as part of a preventative maintenance service:

- Inspecting and lubricating lift chains

- Checking hydraulic hoses for wear, cracks, and damage

- Inspecting brakes for wear and stopping effectiveness

- Changing the hydraulic fluid and filter(s)

- Inspecting all safety guards (including the overhead guard), safety equipment (e.g. lights, alarms, fire extinguishers), and the presence and legibility of all decals and nameplates

- Replacing wearable parts, like switches, brushes, contactor tips, bearings, etc.

- Inspecting the forks for wear and damage

- Ensuring all manuals and any other required documents are present

It’s important to note that only qualified and authorized personnel should maintain and inspect industrial lift trucks. If you need help maintaining your order picker (or fleet of order pickers), contact us today. You can also read more about our forklift maintenance services and benefits.

Frequently Asked Questions About Order Pickers

What Is an Order Picker?

An order picker is a type of forklift that allows workers to manually place or retrieve stock in high-racking applications. Order pickers can be used as a faster, safer alternative to ladders, scissor lifts, and other tools or pieces of equipment.

What Is the Difference Between an Order Picker and a Forklift?

An order picker is a type of forklift.

Operators use order pickers to move single items in narrow aisles for order fulfillment. Forklifts can lift many items all at once via a pallet. Also, order pickers are typically smaller and more maneuverable than forklifts.

Why Would I Want an Order Picker?

Order pickers help warehouse workers with inventory, identifying, and moving single items. Since pulling an entire pallet down to remove just one or 2 items is inefficient, order pickers allow operators to reach the pallet high up and remove a single item.

When Are Order Pickers Used?

Warehouses and fulfillment centers use order pickers for order fulfillment applications. For instance, you may need an order picker if you’re frequently removing individual items from shelving.

You also need them when navigating narrow aisle environments. Especially if you’re looking to maximize space and capacity by moving pallet racking closer together.

How High Do Order Pickers Go?

Order pickers go between 9 and 35 feet up to the rack, with or without a load. Some larger models can go up to 45 feet.

Do You Need a License for an Order Picker?

You do need a license to operate an order picker in the workplace, as per OSHA requirements. We’ve captured the order picker licensing requirements in our Is Online Forklift Certification Legit? post and our forklift license guide.

Why Are My Order Picker’s Hydraulics Disabled?

If your order picker controls aren’t working, start with these simple troubleshooting steps:

- Is the key in the “On” or “Start” position?

- Is the dead man pedal pressed?

- Is the battery low?

If you check these items and are still having a problem, refer to our common forklift repairs post for more information on what could be wrong. Or contact your nearest authorized repair center for help.

Conclusion

That’s it: Everything you need to know about order pickers.

![What Are Order Pickers? [Definition, Types, Pros/Cons, Uses]](https://www.conger.com/wp-content/uploads/2023/02/What_Are_Order_Pickers_Featured_Image-Copy.png)