Wondering what an RF scanner is?

You’re in the right place. Because in this article, you’ll learn:

- What RF scanners are

- How RF scanning works

- What RF scanners are used for

- The different types of RF scanners

- How to choose an RF scanner

- And LOTS more!

Let’s dive in!

What Is RF Scanning?

Have you ever wondered: “What is a warehouse RF scanner?”

Radio frequency scanners – or “RF scanners” for short – are electronic devices used to automate data entry of physical items into databases or computer systems so they can be logged, tracked, and managed.

Other Names for RF Scanners

RF scanners are also sometimes called other names like “RF terminals,” “barcode scanners,” or “handheld barcode readers.”

What Do You Need an RF Scanner for?

Why use RF scanners in a warehouse?

RF scanners help bridge the gap between warehouse management systems (WMS) and human workers and automate the process of directing workers to their next tasks.

Moreover, RF scanners for warehouses are often mobile and handheld, allowing workers to walk with them around the warehouse.

Here are some of the key benefits of using RF scanners in the warehouse:

- They are versatile. RF scanning can be used for picking, put-away, stock replenishment, and shipping and receiving operations

- They’re a paperless option. Over 50% of warehouses use paper. RF scanning can reduce paper usage and reduce the time order pickers waste handling paperwork for each order

- More accurate picking. RF scanning systems automatically update in regular intervals, ensuring greater accuracy in stock levels and item movements

- Less room for error. The results of each scan can be shown immediately on the screen and/or in the warehouse management system (WMS) so errors can be caught

- Flexibility for custom implementation. Warehouses can use RF scanning alone or in concert with other technologies, like RFID scanning and voice-picking

RF vs. RFID: What’s the Difference?

The terms “RF” and “RFID” are often used interchangeably. But although the “RF” in both stands for “radio frequency,” key differences remain between the two technologies.

| RF | RFID | |

|---|---|---|

| Stands for | “Radio frequency” | “Radio frequency identification” |

| Scanning range | Requires line-of-sight | Doesn’t need physical contact or line-of-sight |

| Basics | Uses lasers or images to read barcode labels | Uses radio waves to identify tags attached to items |

| Scanning efficiency | Can only scan one item at a time | Can scan many items simultaneously (for example, scanning all the contents of a pallet) |

| Expense | Cheaper (a few cents per tag) | More expensive ($1 to $30+ per tag) |

| Information capacity | Less information conveyed | More information conveyed |

| Security | Less secure | More secure |

| Power source | None | Battery-powered or passive (tag receives power from the RFID reader) |

| Interference | Less prone to outside interference | Prone to interference (e.g., from metals and liquids) |

What Other Industries Use RF Scanning?

It’s not just warehouses that use RF scanning – many other industries do as well.

Here’s a list of those industries, along with a few specifics of how they’re often used:

- Retail and grocery: Scanning and checking out items consumers purchase – this is technically called “point-of-sale” (POS) transactions

- Sales and marketing: Administering customer loyalty and reward programs

- Healthcare: Admitting patients and verifying correct medication distribution

- Manufacturing: Inventory management and asset tracking

- Logistics and parcel delivery: Item scanning and tracking, fleet management, pickup and delivery operations

- Food: Tracking from farm to table for better food safety

- Utilities: Taking meter readings to calculate energy usage

- Education: Asset, attendance, and document tracking; staff communication

- E-Commerce: Order fulfillment and tracking

- Military: Weapons, equipment, maintenance, and repair tracking

What’s All Part of an RF Scanning System?

For an RF barcode scanner system to work, it needs a variety of components, including

- Barcodes or labels: These are attached to the goods and contain embedded information about them

- Mobile RF scanner device: These link the worker and the warehouse management system and consist of a light system, sensor, and decoder

- Wireless network connection: This can be radio frequency, Wi-Fi, 3G, 4G, or 5G systems. These networks provide the means for transferring information between the scanners themselves and the WMS

- Wireless access point: Also known as the “base station,” this is the component that receives a radio signal from the scanner itself and sends it to the WMS

- Server and database: These electronic systems digitally hold the inventory, orders, and shipping data

- Warehouse management system: Often abbreviated as “WMS,” this is the software system that functions as the warehouse’s “brain.” It knows what items are in the warehouse’s inventory, where they are, and how many items there are

How Does RF Scanning Work?

Now that you know what all comprises an RF scanning system, let’s discuss the specifics of how it all works together.

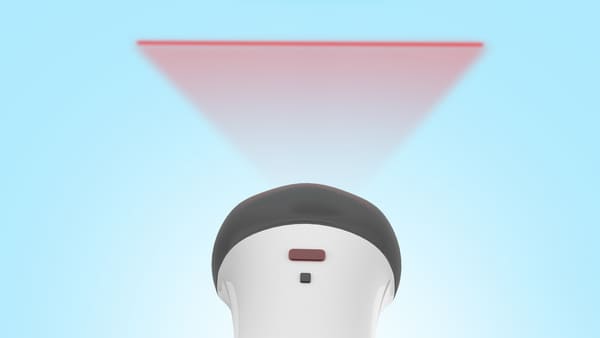

To scan an item, an RF scanner relies on a light source to illuminate the barcode with red light.

Additionally, the scanner will have a sensor to detect the reflected red light from the barcode.

This generates an analog signal, which is sent to a decoder.

The decoder does several things, including:

- Receiving the analog signal containing the barcode’s information

- Interpreting and validating the analog signal (and thus the barcode’s information)

- Converting the signal to text and sending that text to the computer system

For example, a warehouse management system holds a “master” set of data about all the products in the warehouse.

The system compares the data it has on hand to the text it receives from the scanner to verify the item’s identity.

The WMS then logs the text into its database and decides what should be done with the item: whether it moves on to storage or heads toward another warehousing process.

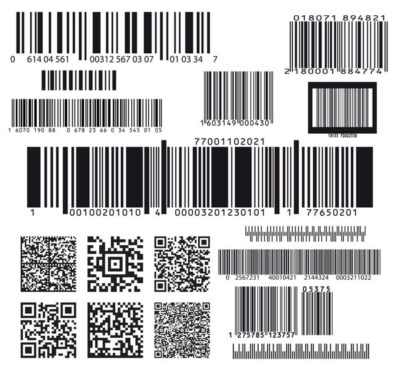

What Types of Labels Can RF Scanners Read?

One-dimensional RF scanners can read basic barcodes like UPCs (the kind you see in the grocery store, for example).

Two-dimensional scanners – also sometimes called “image scanners” – can read basic barcodes as well as 2D barcodes, which include QR codes.

How Is RF Scanning Used in Warehousing?

Here are some specific ways that RF scanning is used in warehousing operations:

Receiving Goods

Once offloaded from a delivery vehicle, workers use RF scanners to scan each item.

The WMS tallies the goods scanned and compares them to what’s on file to ensure a match.

Order Picking

RF scanners reduce mistakes associated with manually picking and processing orders.

They direct workers to the correct aisle containing the item(s) to be picked, communicate the quantity to pick, and signal where each item is to be sent for further processing.

Quality Control

Workers can quickly and easily scan items to quickly identify defective products, check expiration dates, and ensure timely shipment dispatch and arrivals.

Equipment Tracking

Barcodes and scanners can help monitor the use and maintenance of equipment.

They can also help quickly identify parts needed for repairs and even contact vendors to automate the reordering process.

Order Confirmation

Upon scanning incoming shipment barcodes, the scanner/WMS can send confirmation notifications to their supplier companies.

Storage Utilization

By tracking inventory, RF scanners can provide data about how well warehouse storage space is utilized.

Warehouse operators can use this data to improve storage density figures to store more goods in limited space.

Inventory Management

Using an RF unit for inventory helps keep a digital log of what’s in the facility and where it’s located, making inventory management more efficient and accurate.

How to Use an RF Scanner Gun

Sometimes, it’s better to see how to use something than it is to read it. So, check out the videos below or follow the summarized steps in the text below:

How to Use the Buttons and Functions of an RF Scanner

Note: The video above and steps below are based on Intermec (Honeywell) RF scanners and may vary between scanner models

Watch the video above to learn how to do the following basic RF scanner functions:

- Replacing the battery

- Powering the unit on

- Moving between screens

- Scrolling up, down, and side-to-side

- Scanning and entering data manually

- Displaying options using function keys

- Selecting options

- Correcting mistakes

How to Use an RF Scanner for Receiving Goods

Note: The video above and steps below are based on Intermec (Honeywell) RF scanners and may vary between scanner models

- Get the bill of lading and packing list from the delivery driver

- Log into the scanner (enter username and password, if prompted)

- Select the correct activity: “Receiving”

- Scan the “transfer order” barcode on the packing list

- Scan the item’s barcode (the scanner won’t accept barcodes not associated with the scanned order – so, keep scanning until you find the right one)

- Confirm receipt of the correct quantity when prompted by the scanner

- Use a marker to cross through the barcode on the received box (so you know what you’ve scanned)

- Continue scanning until all items are received

- Update the statuses of any missing shipments in the scanner

How to Use an RF Scanner for Picking in a Warehouse

Note: The video above and the steps below may vary between RF scanner models

If you’re wondering: “How do I use an RF scanner to pick orders?” then follow the steps below:

- Prepare the scanner: Get a freshly-charged battery, install it, and test to ensure the battery is secure; then check for damage to the scanner lens

- Turn the scanner on and sign in with your username and password

- Choose the “outbound” warehousing process (since picking is an outbound process)

- Choose the “picking” warehousing process

- Move to the aisle containing the specific section of shelving where the first item to be picked is (for example, the scanner may give the location code: A-09-P410-30, where: “A-09” refers to “aisle 9” and “P410-30” is the specific location in shelving where the item is located)

- Scan the barcode attached to the shelving (to verify you’re in the correct spot)

- Scan the barcode attached to the item (to verify it’s the correct item)

- Enter the quantity picked into the scanner

- Place the item in the storage container that the scanner indicates (for example, in a tote on a rolling cart)

- Scan the barcode attached to the storage container (this updates the system that the item is temporarily in a particular location)

- Move to the next item to pick as indicated by the scanner

- Complete the previous steps until all picks are made

What Are the Benefits of RF Scanners?

Better Storage Utilization

One of the main aspects of managing a warehouse is making the best use of the existing space.

RF scanners can help with this by enabling warehouse operators to keep track of where their stored goods are being used and where they are not.

Using this data, warehouse operators can make important decisions about where to eliminate space for items not in stock for more efficient storage utilization.

That can also include adopting storage utilization models like “random storage,” which allows the movement of goods in storage based on where space is available at any given moment.

The result of this is that warehouse operators will be better equipped to accommodate inventory peaks – such as around the holidays – more easily.

Fewer Mistakes

Using a combination RF scanning system with a warehouse management system is the first step in replacing pen-and-paper systems.

And in doing so, there’s less need for manual data entry, which reduces error in turn.

For example, you won’t worry about misplacing papers, which could lead to loading and shipping mistakes.

After all, all the critical information about items in stock is already held digitally in the warehouse management system and continually updated with each scan of the RF scanner.

Moreover, RF scanners can call attention to errors in shipping or receiving, allowing improper shipments to be set aside or refused.

Lower Costs

Though RF scanning costs more than paper and pen methods, it does offer many opportunities for cutting costs in the long run:

- Immediately reduce the number of workers doing manual tasks like data entry

- Eliminate redundant administrative tasks

- Reduce the costs associated with inventory and shipping mistakes

- Reduce seasonal/temporary labor costs during demand peaks

- Verify inventory levels for customers without going and physically looking

- Train workers faster and easier due to the ease of use of RF terminals

- Reduce overtime pay, since one worker with an RF scanner can get much more done – and do so more quickly – than a worker using manual means

- Lower capital investment compared to other systems, like pick-to-light

- Capture additional revenues by adjusting for market price fluctuations in real-time

Better Inventory Control

At its core, RF scanning is really about making inventory management that much easier and more accurate.

How?

For one, warehouse operators can instantly know the location of each particular product, the quantity, and other important data.

Moreover, all product movements are recorded, preventing any unforeseen accidents or delays.

And with better product traceability comes the ability to trace products back to the manufacturer.

This can be critical if something goes wrong and needs to be returned.

In terms of performing manual inventory counts, using a WMS and RF scanning system may even eliminate the need to perform manual inventory or cycle counts, which are time-consuming and prone to waste.

There’s also no waiting for paper documents to be processed before inventory counts can be returned.

Plus, systems can automatically update and check for errors, eliminating emergencies and losses.

Improved Productivity

Manual inventory tracking is extremely time-consuming.

By automating this process, RF scanning can dramatically improve productivity in the following ways:

- Handle more orders and shipments, including during peak periods

- Eliminate guesswork and instantly know where to put items away

- Track which employees are doing what and their productivity level

- Automatically assign tasks to workers according to “zones”

- Improve mobility with radio, Wi-Fi, 3G, 4G, and even 5G wireless technologies

Types of RF Scanners

There are many types of RF scanners. But they can be broken down into 2 main categories: By technology and by form. Let’s go through the most popular types in each category.

Types of RF Scanners by Technological Sophistication

Laser RF Scanners

Laser scanners are the most basic, common, and familiar type of RF scanners.

They use light from a laser beam to shine on barcodes, and the reflection is used to read the barcode information and identify the product being scanned.

Laser scanners read linear 1D barcodes – the most basic type of barcode – and usually have a scanning distance range of 6 inches to 2 feet.

They’re useful for handling consumer goods that often experience a property change, such as price fluctuations since the technology allows for easily updating prices.

Advantages of Laser RF Scanners

- Cheapest type of RF scanner

- Simple to operate

- Scan distances up to 24 inches (some models can read greater distances than that, depending on the barcodes)

- Powered by a cord, though some can be battery-powered for portability

Disadvantages of Laser RF Scanners

- Can only read linear one-dimensional (1D) barcode symbologies, like UPCs (they can’t scan QR codes)

- Can have difficulty reading damaged barcodes

- More susceptible to damage because they have more moving parts

Image Scanners

Instead of using light and reflections like laser scanners, image barcode scanners use a small digital camera to capture an image of a barcode.

Image scanners are becoming more popular thanks to their ability to scan more items faster.

Not only that, but image scanners can also scan both 1D and 2D barcodes.

This means they can handle more robust collections of information about items, like images, pricing, voice data, and website addresses.

Advantages of Image Scanners

- Work with more barcode types than laser scanners, including 1D and 2D/QR barcodes

- Can scan barcodes on computer and smartphones screens

- Can read barcodes from any angle or orientation for faster scanning

- Work on smaller barcodes, making them great for use with small items that a regular barcode couldn’t fit on

- Fewer moving parts, making them more durable than laser scanners

- Can read damaged barcodes better than 1D laser scanners

- Scanning range can be from a few inches to 24 feet away (depending on the size of the barcode)

Disadvantages of Image Scanners

- More expensive than 1D laser scanners

Mobile Computers

Mobile computers are handheld devices that combine the capabilities of basic barcode scanners with those of computers.

This gives them the functionality of an RF scanner with the processing power of a laptop in one wireless device.

Moreover, mobile computers use common operating systems, like Windows, Linux, and Android, and can even connect to “the cloud.”

This combination of computing power and wireless capabilities makes them popular in large warehouses, where they’re used for receiving, storage, picking, packing, and shipping.

Advantages of Mobile Computers

- Most powerful of all RF scanners

- Can scan a large variety of barcodes and labels, including 1D and 2D symbologies

- Captures digital images and allows instant updates and edits on captured data

- Compatible with various wireless technologies like Wi-Fi, 3G, and 4G networks

- Can save scanned data offline if no network is present and upload it once a connection is established

- Can be “ruggedized” with protective casings to withstand the rigors of everyday use in working environments

Disadvantages of Mobile Computers

- More expensive than basic barcode scanners

- Uploading data to the cloud or the web may introduce vulnerability by exposing that information to nefarious actors like scammers and hackers

Types of RF Scanners by Form

Below are 6 of the most common forms of RF scanners.

Handheld RF Scanners

Most RF scanners are handheld, either wired or wireless.

This is likely because of how easy they are to use.

A worker simply holds the scanner, points at the barcode, and presses the button.

The rest – including data transfer, conversion, and storage – is done automatically and the worker can move on to the next item to scan.

Handheld scanners are useful in nearly any industry where barcodes are used, such as healthcare facilities, grocery stores, and warehouses.

Wearable RF Scanners

These scanners can be completely wireless or connected by a cable to a wrist-mounted computer.

Most of them are imagers and scan 2D barcodes.

But 1D laser and linear models also exist.

Overall, wearable scanners are valued for their lightweight, ergonomic design and for enabling workers to quickly scan items.

Presentation RF Scanners

Unlike handheld RF scanners, presentation scanners are stationary and work by scanning items that are placed in front of it – as opposed to bringing the scanner to the items.

With a wide scanning angle, this type of scanner can scan multiple barcodes in succession within a relatively wide area.

This ability makes them especially useful in retail checkouts where they can be moved around to accommodate scanning different-sized items.

Encounter RF Scanners

Like presentation scanners, encounter scanners are stationary and instantly scan items as they’re swiped across the reader.

But unlike presentation scanners, encounter scanners are designed to be mounted to a scanning surface, such as a checkout station.

You’re most likely to find these scanners in grocery stores and self-checkouts.

Fixed-Mount RF Scanners

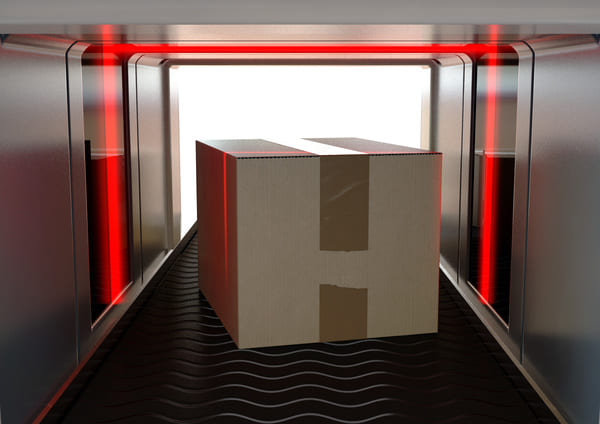

Fixed-mount scanners are designed to scan items or materials automatically at high speeds, making them perfect for keeping up in fast-moving manufacturing applications.

They are often integrated into larger processes where scanning individual items is necessary, such as items passing along a conveyor line.

They’re commonly used in large, specialized operations like warehousing, manufacturing, and logistics.

Vehicle-Mount RF Scanners

Vehicle-mount scanners are a type of fix-mount scanner consisting of a barcode reader and computer system mounted to a vehicle like a forklift.

The key advantage of these scanners is that workers can scan items, pallets, cartons, etc. right from their vehicle, saving them time and physical strain.

These scanners are commonly used in manufacturing, warehousing, and logistics.

How Much Do RF Scanners Cost?

RF gun prices can vary widely based on the technology and the form.

The cheapest handheld 1D laser scanner on Amazon can be bought for $13.98. New handheld 2D image scanners go for about $29.

Older, refurbished wireless RF scanner guns and bases can be bought for about $38 apiece online.

For mobile computers, the low-end cost is about $600, while other models can cost $1,500 or more. Finally, certain “ruggedized” scanners can cost more than $2,500.

How to Choose an RF Scanner

With so many different RF scanner options, how do you choose the right one? Follow these simple tips to help you make the best decision.

What Is Your Budget?

What you can afford is the most obvious place to start when choosing an RF scanning system.

As noted in the “prices” section above, simple 1D and 2D scanners can cost $15 to 50 apiece – not exactly “bank-busting” sums of money.

But as with anything, the more sophisticated the system, the more it will cost.

So while you may want a mobile computer system ideally, you have to balance what you can afford with what capabilities you need.

What Do You Want the Scanner to Be Able to Do?

Speaking of capabilities, how much sophistication do you need?

Basic laser scanners can work with basic UPC barcodes, but won’t be able to handle additional data that is embedded in 2D barcodes like QR codes have.

On the other hand, mobile computers offer much more advanced inventory management options which can make tasks like order picking significantly more efficient.

How Many Items Will You Handle?

The fewer items you have to scan and handle, the simpler your chosen RF scanner can be.

For example, a barcode scanner may work just fine for small warehouses or retail stores that handle only a few hundred SKUs.

On the other hand, a massive warehouse or fulfillment center might benefit from a more robust network of mobile computers.

How Often Will You Be Scanning?

Longer inventory scanning periods require long-lasting batteries.

If workers can remain stationary while scanning, you can avoid downtime caused by dead or dying batteries and instead use wired power.

But, if workers will be moving across the facility or working outdoors for long periods, a fixed power source won’t be an option.

In those cases, you’ll need a scanner with both wireless capabilities and lost-lasting batteries.

How Big Is Your Scanning Range?

Like the factor above, this one goes to portability.

Ask yourself: Can the scanner stay connected to a computer within the scanning range?

If so, a wired scanner may be an acceptable option.

But if your workers are constantly on the move while scanning, you’ll need a wireless option.

What Are You Scanning?

There are various labels or tags you may work with, like 1D barcodes, 2D barcodes, and RFID tags.

But recall that not all RF scanners are compatible with every type of label.

Thus, you’ll need to ensure whichever device you choose is compatible with the tags or labels you work with: Laser RF scanners for 1D barcodes; image scanners for 2D and QR codes; and RFID for tags.

Tip: If you’re currently using 1D barcodes but you think you might change to 2D barcodes in the future (for example, to be able to use QR codes), save money by buying a scanner that does both now.

What Is Your Scanning Environment Like?

Not all workplaces are created the same.

Thus, the same piece of equipment – like an RF scanner – won’t be as effective in some environments as others.

For example, retail outlets may not be as abusive as cold storage warehouses.

So, the physical resilience of your chosen scanning device is critical:

- What type of durability do you need?

- Will you be scanning indoors or outdoors?

- Will the scanner be exposed to drops, dust, cold, heat, or water?

Also, consider how well your barcodes maintain their integrity – image scanners will be better than laser scanners for reading damaged barcodes.

Need help choosing an RF scanning system for your warehouse? Contact Conger Industries today to learn how we can help.

Frequently Asked Questions About RF Scanners

How Does Barcode Size Impact Scanning Distance?

Barcode size and scanning distance are directly related. The greater the distance between the scanner and the barcode, the bigger the barcode must be.

Not only that, but the barcode must also have sufficient dots per inch (DPI) and be printed with retro-reflective characteristics to ensure the scanner can read them.

Are All Barcode Scanners the Same?

Not all barcode scanners are the same or can read all the different types of barcodes in existence.

For example, most laser scanners can only read 1D barcodes. But 2D scanners can read both 1D and 2D barcodes (like UPCs and QR codes).

What Are “Rugged” Barcode Scanners?

Rugged scanners are sealed to guard against the rigors of daily use in busy environments like warehouses.

For example, some models are built to withstand multiple 6-foot drops along with exposure to extreme temperatures, water, shock, and dust.

Although they’re more expensive than standard scanners, ruggedized scanners will save you money in the long term by not having to replace them due to abuse/damage.

You can often spot this type of scanner by its brightly-colored case (for better visibility).

Conclusion

That’s it: The ultimate guide to RF scanners.