This is your complete guide to forklift speeds.

We’ve put together everything you need to know, including:

-

How fast forklifts can travel

-

What OSHA says about forklift speed

-

Industry-standard forklift speed limits

-

How to calculate a safe forklift speed

-

Tips for safe forklift travel

Let’s dive in!

Quick Summary

Don’t have time to read the entire article? Here’s a quick summary of the main points:

- There’s no defined OSHA forklift speed limit. Instead, OSHA leaves it up to employers to determine a safe forklift speed.

- The Material Handling Equipment Distributors Association (MHEDA) “recommends a max speed of 8 mph in general and a 3 mph max speed in high pedestrian traffic areas.”

- A common forklift’s max speed is 10 miles per hour. However, many businesses set their forklift speed limit at 5 mph, particularly if working around pedestrians, forklifts, or other equipment.

- The risks of speeding forklifts include compromised steering, risk of tip-overs, reduced ability to stop, and fines and penalties.

- When determining a safe forklift speed, consider your general work environment, operator visibility, forklift and tire type, pedestrian and equipment traffic, and safe stopping distances.

- At 9 mph, it can take over 51 feet to bring a forklift to a full stop. It takes about 7 feet of travel between the time a forklift operator recognizes the need to stop and applies the brakes. It takes an additional 10 feet to stop the truck once the brakes are applied.

- Strategies for reducing forklift speeding in the workplace include: Providing quality forklift operator training, enforcing speed limits internally, installing forklift speed control, using forklift telemetry and impact managers, installing speed alert radar systems, and installing forklift speed bumps.

What Does OSHA Say About Forklift Speed?

There’s no defined OSHA forklift speed limit.

“OSHA does not have specific speed limits set for the safe operation of a powered industrial truck.”

OSHA’s standard letter of interpretation

Instead, OSHA leaves it up to employers to determine a safe forklift speed.

OSHA Standards That Address Forklift Speed

Though they don’t mandate a forklift speed limit, OSHA does provide some related guidelines in the following standards:

-

1910.178(n)(1)

Operators must observe all traffic regulations, including authorized facility speed limits. They must maintain a safe distance, about three truck lengths from the truck ahead, and always keep the truck under control.

-

1910.178(n)(4)

The operator must slow down and sound the truck’s horn at locations with vision obstruction and cross aisles. If the load on the tusk obstructs the forward view, traveling with the load trialing is advised.

-

1910.178(n)(8)

Drivers should always operate the truck at a speed that allows it to be stopped safely.

-

1910.178(n)(9)

Stunt driving and horseplay aren’t permitted.

-

1910.178(n)(10)

The operator must slow down on wet and slippery floors.

-

1910.178(n)(11)

Secure dock boards or bridge plates before driving over them, and proceed slowly and carefully while never exceeding their rated capacity.

-

1910.178(n)(12)

Approach elevators at slow speeds, and enter them squarely after ensuring the elevator car is properly leveled. Once the truck is in the elevator, power it off, neutralize the controls, and set the brakes.

-

1910.178(n)(15)

Reduce speeds to a safe level while negotiating turns and turn the hand steering wheel in a smooth, sweeping motion.

Industry Consensus Forklift Speed Limits

Since there’s no predefined forklift speed limit, you might be wondering if there’s an industry standard or consensus.

One group we can reference is the Material Handling Equipment Distributors Association (MHEDA), which is a non-profit trade association centered on material handling equipment.

MHEDA “recommends a max speed of 8 mph in general and a 3 mph max speed in high pedestrian traffic areas.”

MHEDA

But this is simply a guideline instead of a rule.

As such, some companies increase or decrease their lift trucks’ speed limits to accommodate the specifics of their operation.

For example, many businesses set their forklift speed limit at 5 mph, particularly if working around pedestrians, forklifts, or other equipment.

Why It’s Important to Set Forklift Speed Limits

Forklifts are heavy machines.

This makes speed a great risk factor when operating them since a forklift that can’t stop in time can easily turn into a 10,000 lb. missile.

Let’s discuss some of the risks of speeding forklifts below.

Compromised Steering

It’s easy to understeer when speeding on a forklift, which can cause a loss of control.

This also comes with the risk of collisions with people, equipment, infrastructure, products/materials, and walls.

In fact, OSHA says that forklift trucks striking pedestrians is the number one cause of lift truck-related work fatalities.

Risk of Tip-Overs

According to OSHA, forklift tip-overs (overturning) are the second leading cause of fatal accidents in warehouses and factories.

Many tip-overs result from high speed, which can cause instability, especially when rounding corners.

This is why operators are advised to reduce speed around corners as well as turn the steering wheel in a smooth, sweeping motion to prevent excessive sway.

Reduced Ability to Stop

Speeding increases the distance required for the forklift to stop safely.

This can lead to collisions with people, other machines, and infrastructure and result in damage to forklifts, fatal injuries, and other accidents.

It also puts workers and machines at risk of falling from docks when approaching at an inappropriate speed.

In fact, falls account for about 25% of all reported injuries at loading docks.

Fines, Penalties, And Losses

Speeding on a forklift can cause not only great human costs but also financial and other business penalties, like:

-

OSHA fines

-

Worker’s compensation

-

Downtime

-

Medical bills

-

Legal bills

-

Reputation damage and lost customers

-

Compromised employee morale

How to Determine a Safe Forklift Speed Limit

Setting a safe forklift speed limit involves balancing the need for workplace safety with the ability to achieve production goals.

If the speed is set too high, safety can be compromised.

But if it’s set too low, productivity will suffer.

Overall, it involves some trial and error to balance the two.

So, how do you determine a safe forklift speed?

Let’s go through some of the key considerations.

Consider Your General Work Environment

No two business operations are exactly the same.

That makes it necessary to consider any characteristics unique to your operation which may negatively impact safety with respect to the maximum speed your lift trucks can travel.

For example, what is the terrain type? Is the ground rough and uneven? Or are you operating on smooth floors?

Forklift speed limits in rough, uneven terrain like a construction site are different from a smooth or level surface like inside a warehouse.

This is because lift trucks are more susceptible to tip-overs or sliding on uneven terrain than on level ground.

Also, consider what’s on your floors.

Dust, oily surfaces, humidity, or moisture accumulation on the floor increase braking distance, which limits a forklift’s maximum speed.

Another factor is inclines and declines, such as ramps and loading docks.

On these terrain types, you’ll need to keep the truck’s speed lower – especially when going down slopes where speed invariably increases.

Consider Operator Visibility

Speed should not impact an operator’s vision.

Thus, slow speeds are recommended in areas where operators have blind spots, such as when crisscrossing aisles and backing up.

In these cases, it’s recommended to slow down and sound the horn when navigating aisle intersections, corners, and other sight-limiting obstacles.

Consider Your Forklift and Tire Types

Not all forklifts are built the same.

Some are heavier to handle weightier loads while others are light for light-duty tasks.

It’s essential to keep in mind that heavier loads require operators to be more cautious about their speed.

The more weight a forklift carries, the longer it takes to stop, making it more difficult to avoid pedestrians, infrastructure, and equipment.

On a related note, you should also consider the lift truck tire type – specifically if it has cushion or pneumatic tires.

This is because cushion tires generally don’t provide as much traction as pneumatics, especially on wet or cold surfaces, such as in cold storage warehouses.

Consider Pedestrian Traffic

As we’ve noted, forklift accidents involving pedestrians are one of the top causes of injuries in the workplace.

So when setting a safe forklift maximum speed, it’s critical to consider the number and proximity of pedestrians to your lift trucks.

In general, it’s a good idea to impose speed limits in parts of the facility where there is more pedestrian traffic or obstacles to avoid.

Furthermore, separating the area between pedestrian traffic and forklift traffic can help reduce accidents.

And finally, operators should never drive up to a pedestrian in front of a fixed object or wall.

That can cause them to become pinned and cause great injury or worse.

Consider Safe Stopping Distances

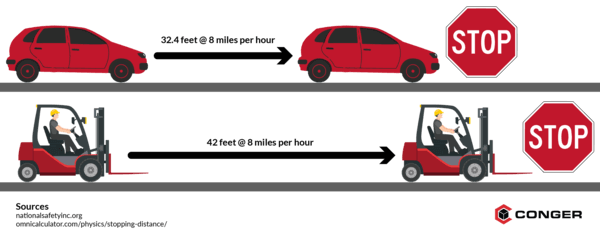

Forklift top speed is related to stopping distance.

This is because the faster the lift truck is traveling, the longer it takes to stop.

Compounding the issue is the fact that forklift brakes aren’t as effective at stopping as road vehicles.

This is because road vehicles have brakes on all 4 wheels, but forklifts only have brakes on the front 2 drive wheels.

So, determining a forklift’s safe stopping distance can help you set safe forklift speed limits in the facility since you’ll be able to estimate how long it takes to stop at certain speeds.

How Long Does It Take to Stop a Forklift at Full Speed?

At 9 mph (which is about the average forklift’s top speed), it can take over 51 feet to bring a forklift to a full stop.

It takes about 7 feet of travel between the time a forklift operator recognizes the need to stop and applies the brakes (assuming the operator is entirely conscious of their surroundings).

It takes an additional 10 feet to stop the truck once the brakes are applied.

Other guidelines for forklift stopping distance at certain speeds are:

- At 4 mph, the forklift needs 17+ feet for a full stop.

- At 8 mph, it needs 42 feet for a full stop.

It can take a considerable distance to fully stop a forklift, so it’s critical to maintain 20+ feet from pedestrians, trucks, and objects to avoid impacts.

How to Calculate Forklift Stopping Distance

This calculation is only for illustration purposes. Furthermore, it only applies to “dry clean asphalt, brushed concrete, or equivalent surface[s].” Other surface types can increase stopping speed. To determine a safe stopping speed, you’ll need to consider your work environment, forklift types, load types, and more. Proceed at your own risk.

The formula for calculating forklift stopping distance is S = 0.394v2/D – G, where the formula values stand for:

- D = Drawbar drag (25 for 25%)

- G = Percent grade (5 for 5%)

- S = Distance to stop (measured in meters)

- v = Velocity (km/h)

Here’s an example calculation of forklift stopping distance:

Assuming a forklift is traveling at 5 mph (13 km/h), has a drawbar drag of 25% (D), and the percentage grade is 3% (G), the forklift stopping distance formula is S = 0.394(13)2/(25-3).

Running through the calculation, we get a stopping distance of 3.02 meters (S) or about 10 feet.

6 Ways to Reduce Forklift Speeding

Establishing a forklift speed limit for your business is a smart decision.

However, forklift safety will only improve if that limit is adhered to.

Here are some effective strategies to help reduce speeding in your workplace.

Provide Quality Forklift Operator Training

This is the first, and perhaps the single best, way to improve forklift safety.

According to OSHA, a quality operator training program can reduce forklift-related workplace accidents by 70%.

If you have an in-house training program for your operators, consider conducting an audit to ensure the program is up-to-date and includes all the required topics.

If you find deficiencies, consider signing up for a forklift train-the-trainer program.

Check out Conger’s forklift train-the-trainer program.

These are designed to equip your safety trainers with everything they need to conduct quality operator training.

If you outsource your operator training, consider carefully who you give the responsibility to.

Factory-authorized material handling dealerships are an excellent way to ensure your outsourced forklift operator training is done by the book.

Consistently Enforce Speed Limit Infractions

Once you establish internal speed limits, you must enforce them to help ensure safety.

Enforcing internal speed limits can include clear communication to operators and posting warning signs.

If you haven’t already, consider placing speed limit signs in noticeable areas to remind drivers not to exceed the maximum speed limit.

Then, ensure you have managers and supervisors keep an eye out for speeding.

Some factors that indicate excessive speeding are:

- Wheel lift

- Tire skidding

- Truck side sway

Keep in mind that operators caught speeding and committing other speed-related infractions must undergo refresher training.

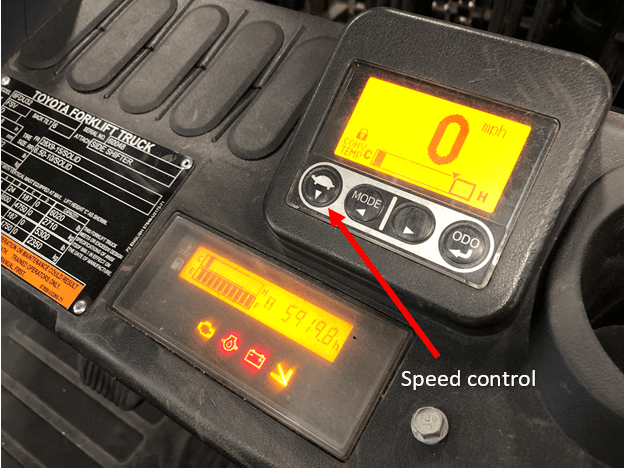

Install or Set Up Forklift Speed Control

You may be wondering: How do I control my forklift speed?

There are 2 options:

- Mechanical speed control

- Electronic speed control

In the mechanical method, aftermarket forklift speed limiter kits are available that can be installed to work on both mechanical and electronic throttles.

They manually limit the engine from going beyond a certain speed – a speed that you (the employer) can dictate.

Other forklifts come with electronic programmable forklift speed control devices.

For example, Toyota forklift speed control comes standard on most models.

In these lift trucks, the maximum speed can be set electronically via the dashboard where access is usually controlled with a passcode.

Either method is effective in controlling speed since the truck itself will not allow the operator to go beyond the predefined speed limit.

Use Forklift Impact Managers

Impact managers are onboard systems that sense when a forklift strikes something and sounds an alarm or alert supervisors.

Although impact managers are more reactionary than proactive in limiting forklift speed, they can help enforce speed limits by improving operator accountability.

Use Speed Alert Radar Systems

A forklift speed radar system is an effective way to discourage speeding.

A speed alert radar works much like radar systems that the police use to monitor road vehicle traffic.

When the radar detects a forklift traveling at a high speed, it shows a visual warning to the operator to “Slow Down” in designated areas.

They can serve as reminders for operators to keep an eye on their speed when approaching areas of heavy pedestrian or equipment traffic.

Install Forklift Speed Bumps

Speed bumps are deterrents that can force operators to slow down when entering or exiting key locations.

Such locations where speed bumps can be installed include areas with high pedestrian traffic, crosswalks, pathways, and intersections.

It is important to note that operators must use caution when crossing speed bumps on a forklift.

According to OSHA, they should be crossed slowly and at a 45-degree angle – not straight across.

Advances in Forklift Speed Control Technology

The latest advances in forklift speed control focus on improving safety and productivity in material handling environments.

AC and DC Drive Speed Controls

Innovations like AC and DC drive speed controls enable more precise control over forklift travel speed, helping operators adjust smoothly in real time.

This technology, especially in electric forklifts, is what allows companies to set specific speeds limits within their facilities.

AC drive systems provide flexible speed adjustments for facilities with varying travel requirements or high pedestrian traffic.

In contrast, DC drive controls offer consistent speed options, which can be preset to align with set speed limits for safer operation.

Employers are now favoring electric forklift speed control systems as they offer a balance between maintaining an efficient workflow and promoting a secure workplace.

Forklift Monitoring Systems

Speed limiting devices and forklift monitoring systems add an extra layer of safety by automatically adjusting forklift speed based on traffic areas and proximity to pedestrians.

With preset and variable speed options, forklifts can meet high production demands without compromising safety.

Using tools like forklift speed limiters and control devices, facilities can customize forklift performance to prevent workplace accidents, especially in narrow aisles and high pedestrian areas.

These advancements in forklift speed control not only help prevent accidents but also extend the lifespan of the equipment by reducing unnecessary wear and tear.

Adopting this technology enables companies to uphold a safe speed policy, reduce workplace accidents, and better manage the safe operation of their forklift fleet, creating a controlled, productive, and compliant material handling environment.

14 Forklift Travel Safety Tips

Keep these tips in mind to improve forklift safety (any relevant OSHA regulations are included):

-

Drive only as fast as you can safely stop and control the lift truck for pedestrians, equipment, and infrastructure

-

Slow down and drive carefully on slick, wet, and slippery floors

-

Do not drive over debris

-

Always keep your view clear. Travel backward with a load or use a spotter if the load blocks your view

-

Consider where you’re operating. For example, if entering/exiting a semi-trailer, you need to limit your speed to avoid accidents

-

Follow all traffic laws if driving on a public road

-

Do not travel with the load elevated. Always keep the load low to the ground (around 4-6 inches) when traveling to help stabilize it

-

Be careful when driving around or crossing intersections or blind spots and take corners carefully. Going too fast around corners can cause the center of gravity to shift outside the stability triangle and result in a forklift tipping over

-

Use caution around docks. Inability to stop can cause you to drive off the dock. Always reduce speed when traveling over dock plates because they can shift and cause a fall

-

Separate forklift and pedestrian traffic. Never drive up to pedestrians who are in front of a fixed object that they can be pinned against 1910.178(m)(1)

-

Drive carefully on ramps, inclines, and graded surfaces, especially when going downslope, because this is when speed naturally increases

-

Slow down and honk the horn at blind spots, intersections, and corners

-

Do not pass forklifts or other equipment moving in the same direction 1910.178(n)(3)

-

Keep a safe distance between forklifts and other equipment

Frequently Asked Questions About Forklift Speed

How Fast Can a Forklift Go?

A common forklift max speed is 10 miles per hour.

But depending on the type and model, forklift top speed is usually between 5 and 15 mph.

What Is the Fastest Forklift Ever?

The fastest forklift ever recorded was 74.5 mph.

This was recorded by police in Australia who witnessed a company’s forklift traveling down a highway.

What Is the Top Speed of a Toyota Forklift?

Here are the speeds of some common Toyota forklifts:

- Walkie stacker: 3.6 mph

- Order picker: 6.5 mph

- 3-wheel forklift: 9.9 to 10.2 mph

- 5,000 lb. warehouse forklift: 10.6 mph

- 12,000 lb. warehouse forklift: 13 mph

- 15,500 lbs. outdoor diesel forklift: 13 mph

How Fast Is a Reach Truck?

Reach trucks usually have max speeds of about 7 miles per hour.

For example, some Toyota and CLARK models can go 6.5 mph when unloaded and up to 7.5 mph when loaded.

How Fast Do Tuggers Go?

Toyota 8TB50 (10,000 lb. capacity) tuggers can go 8.8 mph.

On the other hand, a CLARK 15,400 lb. capacity tugger can go 10.6 mph.

How Fast Can a Pallet Jack Go?

A Toyota 4,500 lb. capacity electric pallet jack can go 3.6 mph.

Manual pallet jacks can go as fast as the operator can walk, but shouldn’t be operated faster than walking speed, which is around 3.5 mph.

What Are OSHA’s Spotter Requirements?

OSHA’s powered industrial truck standards don’t explicitly say that spotters are required.

It only says that forklift operators are required to look in the direction of travel at all times.

“The driver shall be required to look in the direction of, and keep a clear view of the path of travel.”

OSHA standard 1910.178(n)(6)

But spotters can be an effective way of increasing safety with fork trucks, and OSHA does provide some general guidelines for using spotters safely.

Can You Drive a Forklift on the Road?

Driving forklifts on public roads is permissible under certain circumstances.

But you must abide by all state and local traffic, insurance, licensing, and registration requirements.

Also, you may be required to use a “slow-moving vehicle” sign to alert other motorists on the road.

Always check with your local authorities to assess your situation before driving on public roads.

Who Has the Right of Way on a Forklift?

Per OSHA, forklift operators should give pedestrians and emergency vehicles the right of way.

How Many Truck Lengths Should You Maintain Between Forklifts?

Per OSHA 1910.178(n)(1), keep approximately 3 truck lengths between your forklift and the head forklift in a line.

Conclusion

There you have it: Everything you need to know about forklift speeds.