If you’re wondering how to choose the right pallet jack wheels, you’re in the right place.

Because in this article, you’ll learn:

-

What the different pallet jack wheels are

-

What materials each wheel type are made of

-

The factors to consider when choosing pallet jack wheels

-

How much pallet jack wheels cost

Let’s get started!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points.

- Most hand pallet jacks have (4) total wheels: 2 load wheels and 2 steer wheels

- You should replace your pallet jack wheels when they’ve worn 1/4 inch or more, or are damaged, chunked out, cracked, or don’t roll smoothly

- There are 2 main types of pallet jack wheel materials: Polyurethane and nylon

- Polyurethane wheels aren’t as durable as nylon wheels, but they are quieter and don’t mark floors. Overall, poly pallet jack wheels are great for smooth floors, especially in customer-facing applications

- Nylon wheels are harder and more durable than poly wheels. This makes them better for rough or debris-covered floors. However, nylon wheels are louder than poly and are liable to mark floors. Thus, they’re best for use in non-customer-facing applications

- Pallet jacks wheels can cost anywhere from $40 to $60 apiece

Can You Replace The Wheels On A Pallet Jack?

Yes, you can – and you should regularly to maintain optimum pallet jack performance.

Over time, wear and tear can affect performance, making it essential to replace these wheels regularly.

When Should You Replace Pallet Jack Wheels?

You should replace pallet jack wheels once they’re worn down about ¼ of an inch.

This is for both pallet jack steer wheels and load wheels.

For example, if you have 3-inch load wheels, you should replace them once their diameter wears down to 2 ¾ inches.

Or, if you have 7-inch steer wheels, they should be replaced once they’re worn to 6 ¾ inches.

How Do You Measure A Pallet Jack Wheel?

Of course, replacing worn pallet jack wheels requires knowing their diameter.

Not sure what size your pallet jack wheels are?

The best way to measure them is by using a digital caliper.

Then, follow these steps:

- Open the caliper

- Place it over the center of the load wheel

- Note the measurement

Finally, compare the measurement to the original (new) diameter of the wheel.

If it’s ¼ inch or less than the original diameter, then replace the wheels.

Other Reasons To Replace Pallet Jack Wheels

Besides regular wear and tear, other factors that require replacing pallet jack wheels include:

-

Cracked steer wheel hubs

-

Chunking

-

Excessive debris inhibiting the wheel from turning freely

-

Missing tread

-

Damaged entry wheels

-

Entry wheels that don’t easily turn

For pallet jack wheel replacement, always replace load and steer wheels in pairs – even if only one needs replacement.

This is because uneven wear can cause excess stress on the components that the wheels are mounted to.

And this can lead to more expensive repairs in the long term.

How Can You Improve The Longevity Of Your Pallet Jack Wheels?

To avoid frequent pallet jack load wheel replacement, do the following:

-

Remove debris on the floor. This will help prevent chunking and other damage from rolling over the debris

-

Remove dirt and debris from the pallet jack’s wheels. Debris can interfere with both the wheels and axles, making it more challenging to roll freely

-

Avoid moving over drops, slopes, and inclines. This includes curbs and steps, which can cause the wheels to crack

-

Do not overload your pallet jack. Observe its maximum rated lifting capacity to avoid damaging the wheels

-

Do not let the pallet jack sit for long periods with a load on them. This can cause flat spots, especially with poly wheels

-

Lubricate the pallet jack. Including wheels, axles, and bearings. Grease monthly and after each cleaning to keep the pallet jack rolling smoothly

-

Inspect your pallet jack wheels. Do this at least every 6 months to check their condition and replace them when needed

Are All Pallet Jack Wheels The Same?

Pallet jack wheels are not all the same.

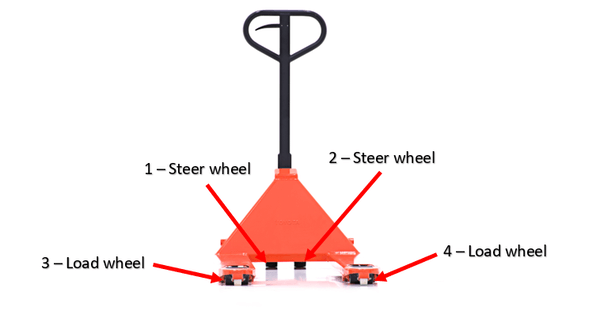

There are 2 different wheel assemblies in pallet jacks:

- Steer wheels

- Load wheels

How many wheels does a pallet jack have?

Most hand pallet jacks have 4 wheels total – 2 steer wheels and 2 load wheels.

However, some can have 2 extra load wheels, for a grand total of 6 wheels.

Let’s go through each type in a bit more detail.

Pallet Jack Load Wheels

Also called “load rollers,” these wheels are small – usually 3 inches or less.

Their small size enables them to get into a pallet’s fork pockets.

Moreover, load wheels don’t swivel.

Instead, they follow the motion of the pallet jack’s fork, which is forward and backward only.

Pallet Jack Steer Wheels

A pallet jack’s front wheels are called “steer wheels.”

They’re larger in diameter than load wheels – usually 7 to 8 inches.

The main function of pallet jack steering wheels is enabling the pallet jack to turn.

To do this, they’re mounted on a swiveling base, which is manipulated using the control handle.

What Are the Parts of a Pallet Jack Wheel?

Pallet jack steer and load wheels are composed of a tread, an axle, and bearings.

The Tread

The tread is molded to the hub and is what makes contact with the floor.

The most common tread materials are nylon and polyurethane. (We’ll cover nylon vs. polyurethane wheels in more detail in the next section).

The Bearings

Bearings are mounted within the hub.

These help the wheel spin by using internal ball bearings to lower friction.

The Axle

Finally, a steel axle fits through the bearing and mounts within a cradle to the fork linkages.

What Are Pallet Jack Wheels Made Of?

The most common materials used to make pallet jack wheels are nylon and polyurethane.

Let’s cover the differences between polyurethane vs. nylon pallet jack wheels.

What Is The Difference Between Polyurethane And Nylon Wheels?

Polyurethane Wheels

Here are the main characteristics, benefits, and applications of this type of pallet jack wheel:

-

Lower rolling resistance. This makes them easier to pull than nylon wheels

-

Ideal for soft floor types. Long-lasting and durable if used on relatively soft floors, like laminated and polished tile

-

Quieter than nylon wheels. That’s why they’re commonly used in customer-facing areas where smooth and silent operation is favored, like retail

-

Less likely to mark or scratch the floor. Another reason they’re favored for customer-facing applications where unsightly marks should be avoided

-

Susceptible to corrosion. Especially if exposed to oil or water. This will corrode the wheels and cause them to break down easily

-

Easily damaged by metal or debris. For applications with debris-filled floors that can’t be regularly cleared, poly wheels are not ideal

Nylon Wheels

Here are the main characteristics, benefits, and applications of this type of pallet jack wheel:

-

Better suited for harsh and debris-filled environments. Tougher, more durable, and less likely to suffer damage than poly wheels in cold storage, wet, or rough floors

-

Good chemical resistance. Ideal for industrial plants, like factories and manufacturing where oil, water, and debris are common

-

Can support heavier loads. Their hard design affords them greater weight capacity than poly wheels

-

Louder and more likely to mark floors. This makes nylon wheels best for behind-the-scenes work where they won’t be facing the public

Types of Pallet Jack Steer Wheels

There are different materials for pallet truck steer wheels available, including:

-

Poly tread with a nylon hub. These don’t mark the floor, roll easily, and are quiet. But, they’re susceptible to flat spots if left with a load on them for long periods. Ideal for display floors, carpeting, and warehouses

-

Ultra-poly tread on an aluminum hub. These roll more easily than regular poly, are non-marking, but can also develop flat spots. Moreover, they’re longer-lasting, very hard, and are less likely to shatter in the cold

-

Solid nylon. These are best for cold storage and places that can cause rust and corrosion, such as poultry or seafood processing. They’re also ideal for use on grated floors, refrigerated transport trucks, and rough pavement. But they are likely to mark the floors

-

Solid steel. These are best for factories, places with metal or hard debris on the floor, and where noise is not an issue. They’re also suitable for rough asphalt

How to Choose the Right Pallet Jack Wheels

Let’s go through everything you should consider when choosing pallet jack wheels.

What Happens If You Choose the Wrong Pallet Jack Wheels?

Choosing the wrong pallet jack wheels can have a lot of negative impacts on your operations, including:

-

Productivity losses. Incorrect pallet jack wheels will wear out more often. This can cause you to experience more downtime replacing the wheels

-

Extra expenses. Replacing your pallet wheels more often than normal incurs the costs of the parts and labor

-

Reputational damage. Using nylon wheels in customer-facing applications, for example, can annoy customers with noise or mark the floors. These can cause customers to develop a bad perception of your business

-

Damage to your flooring. For instance, if you use nylon wheels on polished or laminate floors, you can scratch the floors. This will incur repair or replacement costs, along with more downtime

-

Injury to employees and damage to equipment. Using pallet jack wheels that can’t adequately support the load can cause them to fail. And this can cause injury or damage to products and equipment

-

Unnecessary burdens on workers. The wrong pallet jack wheels may make the load unnecessarily hard to pull and maneuver. This can cause injury, low morale, and further productivity losses

3 Factors to Consider When Choosing Pallet Jack Wheels

Ask yourself the following questions when considering which type of pallet jack wheel is right for your application.

1. What Are Your Floors Like?

Your floor type is the main determinant of the pallet jack wheels you should use.

So, will you be using the pallet jack on rough floors?

If so, consider nylon pallet jack wheels.

You should also consider how well you’ll be able to keep the areas where the pallet jack will be used clear of debris.

If you don’t think it’s possible – or know it’s impossible – to clear debris, consider nylon wheels for their longevity.

Will you be traveling on various surfaces, such as between concrete and steel dock plates?

Take a cold storage warehouse, for example.

You’ll likely be receiving cold goods from a semi-trailer.

Then, the goods will be moved from the trailer, over a dock plate, onto warehouse flooring, and into a cold storage freezer.

A poly wheel won’t last as long in those conditions, making a nylon wheel a better option.

Are you in a rough application with lots of debris on the ground?

Nylon wheels are your best bet if your pallet jacks make long runs, move over wet or rough surfaces, or are used on outdoor ramps and docks.

This is because poly wheels don’t hold up well to rough surfaces.

2. How Important Is It To Keep Your Floors Clean?

In other words, are you in a sensitive, customer-facing environment where marks on the floor would lead to a negative perception?

That may include retail, grocery stores, and the like.

In those cases, choose a polyurethane wheel since they’re less likely to mark the floor.

That said, you might choose nylon wheels if you only use the pallet jack during off-hours when people aren’t in the area.

Just ensure your staff can clean up any marks left behind before customers come into the store.

3. What Is The Noise Level Of Your Facility?

If you don’t want to bother customers and employees with a noisy pallet jack, go with polyurethane wheels.

They’re quieter and don’t make much noise compared to nylon wheels.

What If Your Operation Doesn’t Neatly Fit Into One Category or the Other?

If part of your facility has rough floors and another part is smooth…

Or if you’re partially working in customer-facing areas and partly in warehousing…

You might be wondering what to do.

The best-case scenario is to get 2 pallet jacks if you can afford them.

Pallet jacks are modestly priced, usually around $400 to $600 for a standard 4,500 lb. capacity model.

So, get one pallet jack with nylon wheels for the distribution area and one with poly wheels for the retail space.

But if that’s not an option, you’ll have to weigh some things.

Namely, the cost of replacing the wheels against the particular benefits of each wheel that are important to you.

For example, is the expense of replacing poly wheels more often worth the noise-reduction and non-marking benefits?

If so, then keeping a poly-wheel pallet jack and simply replacing the wheels more often may be your best bet.

How Much Do Pallet Jack Wheels Cost?

Pallet jack wheel prices vary depending on the manufacturer, type, and pallet jack model.

That said, let’s go through roughly what you can expect to pay.

The Cost of Pallet Jack Wheels

Here are the different average prices of varying pallet jack wheel types:

-

Nylon load wheels: ~$40 per wheel

-

Poly load wheels: ~$45 per wheel

-

Nylon steer wheels: ~$55 per wheel

-

Poly steer wheels: ~$40 per wheel

Where Can You Buy Pallet Jack Wheels?

There are 2 main ways to shop for pallet jack wheels:

- You can shop online from retailers such as Amazon, eBay, and Grainger

- You can buy wheels from material handling dealerships (such as Conger)

Which is best for you?

If you know exactly what pallet jack wheels you need, then feel free to check around for the best prices.

Now, the benefit of using a dealership is that they’ll help ensure that you get the right size and material wheels.

That way, you’ll have the peace of mind that they’ll work with your particular pallet jack and application.

Conclusion

That’s it: Everything you need to know about pallet jack wheels.