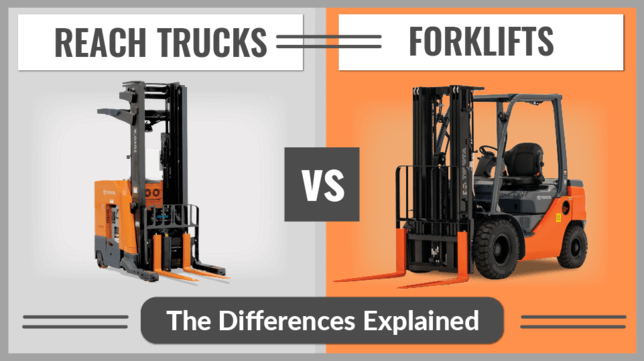

This article explains everything you need to know about reach trucks vs. forklifts.

In it, you’ll learn:

- How reach trucks and forklifts are related

- What applications reach trucks and other forklifts are best for

- How to drive a reach truck

- And much more!

Let’s dive in!

Quick Summary

Don’t have time to read the whole article? Here’s a quick summary of the main points:

- A reach truck is a type of forklift but with the added ability to extend and retract the forks horizontally

- There are 4 main types of reach trucks:

- Single reach trucks

- Double reach trucks

- Moving mast reach trucks

- Multidirectional reach trucks

- There are at least 10 major differences between reach trucks and counterbalance forklifts. The main ones are that reach trucks:

- Use a pantograph mechanism to extend their forks

- Don’t have a counterweight to offset the load

- Are generally made for operating indoors

- Are designed to maneuver in tight spaces like narrow aisles

- Have a lower range of lifting capacities

- Are electric-powered only

- You need training specific to reach trucks to operate them

What Is a Reach Truck?

A reach truck is a powered industrial truck (PIT) designed with a mechanism that allows the forks to extend horizontally.

You may be wondering: Is a reach truck a type of forklift?

Yes, it is.

Specifically, a reach truck is a Class II: Electric Motor Narrow Aisle Truck.

Now, what does a reach truck look like?

Here’s a picture of a reach truck:

Types of Reach Trucks

There are 4 main types of reach trucks.

Let’s go through each.

Single-Reach Trucks

The image above is of a single-reach truck.

And this is the most common type of reach truck you’ll see.

The term “single-reach” means that these models can reach a single pallet position into racking.

As such, they’re ideal for single-deep pallet storage.

Double-Reach Trucks

Also called deep-reach forklifts, these can reach two pallet positions into racking.

The advantage of this is that deep-reach forklift trucks allow warehouses to increase their storage density.

Moving Mast Reach Trucks

Instead of extending the forks, the mast itself on these trucks actually moves forward and backward on rails.

This movement is enabled by a hydraulic system that’s installed on tracks above the base legs.

Multidirectional Reach Trucks

These are essentially a combination of a regular single-reach truck and a moving mast reach truck.

In addition, the load wheels on these lift trucks can pivot from side to side.

This allows the truck to move horizontally without needing to actually turn the entire chassis.

Now, why would this be helpful?

Answer: For handling extra-wide loads.

By not having to turn, the operator can simply travel in the direction of the narrowest part of the load.

And that allows them to move wide materials in narrow spaces.

How Fast Can a Reach Truck Go?

A 36-volt 3,500 lb. capacity Toyota reach truck can travel 7.5 mph.

By comparison, a 36-volt 3,500 lb. capacity Toyota 3-wheel electric forklift can travel 9.9 mph.

What Is the Difference Between a Reach Truck and Counterbalance Forklift?

Now, we’ve said that reach trucks are a type of forklift.

And we’ve covered the different types of reach trucks.

But many differences still remain between reach trucks and other forklifts.

Let’s go through the main ones.

Reach Truck Forks Can Extend

In a typical forklift, the mast only goes up and down – not forward and backward.

But reach truck forklifts can do both motions.

How exactly?

By using a mast in conjunction with a mechanism called a “pantograph.”

The pantograph is what gives reach trucks their namesake function: Being able to ‘reach” into racking to retrieve pallets.

So, how does it work?

A pantograph is essentially a scissor mechanism, driven by a hydraulic cylinder, with forks mounted on the front, and installed within the mast.

When the operator presses a button, the pantograph extends to “reach” into a load.

Then, the operator can retract the pantograph and bring the load back to the closed position.

How Loads Are Balanced

Most forklifts operate based on the counterbalance principle.

This simply means that they use a heavy metal weight on the rear of the truck to offset the weight on the forks.

But reach trucks do not have a counterweight.

Instead, these trucks use base legs to handle the weight on the forks.

Base legs are the components that connect to the reach truck’s chassis and contain the load wheels.

And by absorbing the load in the front, they eliminate the need for a counterweight at the rear.

Operating Environments

Counterbalance forklifts have multipurpose applications.

That is, they can be used indoors and outdoors on various surfaces – depending on the tire type.

One tire type is cushion, which is used for indoor operation.

Other types of tires include pneumatic and solid pneumatic, which are for outdoor purposes.

Warehouse reach trucks, on the other hand, use cushion or polyurethane tires.

And that’s why they’re best for indoor use, where the floor or ground is solid, smooth, and even.

But can you use a reach truck outside?

Only if you have a model designed for outdoor use.

In fact, Toyota has recently released one of these models.

You can learn more about it here.

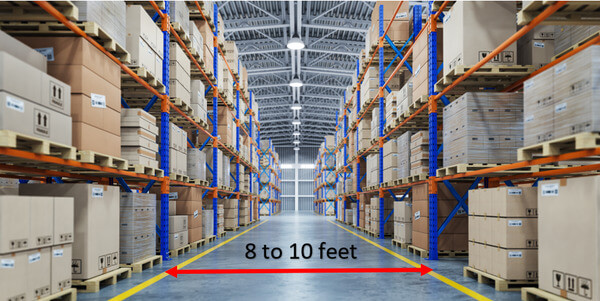

Maneuverability

Counterbalance forklifts tend to have a large footprint and turning radius.

Part of the reason is that they have a longer wheelbase, as well as a counterweight on the back which extends the truck’s length.

Consequently, counterbalance forklifts usually need 10 to 12 feet of aisle space to maneuver.

And that makes them an ideal material handling option for large facilities that don’t have tight spaces.

But since reach trucks have a shorter chassis by design, they can fit in as little as 8 feet wide aisles.

Thus, they’re a great solution for narrow aisle applications – which is why they’re sometimes called “narrow aisle reach trucks.”

Lifting Capacity

Counterbalance forklifts have a much greater capacity range than reach trucks.

In fact, some models of counterbalance lift trucks can handle 100,000 lbs or more.

But reach trucks generally range from 3,000 lbs. up to 4,500 lbs.

So, if you need to handle heavy or oversized loads, counterbalance forklifts are the better option.

Fuel Sources

Reach trucks are only electric-powered, with most models either 24 or 36 volts.

But counterbalance trucks come in a wide variety of fuel types.

This includes:

-

Electric

-

Liquefied petroleum gas (LPG)

-

Diesel

-

Gasoline

-

Compressed natural gas (CNG)

So if you need more power to traverse inclines or carry heavy loads, counterbalance trucks are your best option.

Operator Position

Most counterbalance forklift trucks are sit-down, though some stand-up models do exist.

But electric reach forklifts are the exact opposite.

That is, most are stand-up, while only a few sit-down reach trucks exist.

Additionally, reach truck operators stand perpendicular to the forks.

This allows for better visibility when traveling forward and reverse.

It’s also an advantage if the load is blocking forward sight.

If this happens, reach truck operators can easily reverse without having to strain their necks and shoulders.

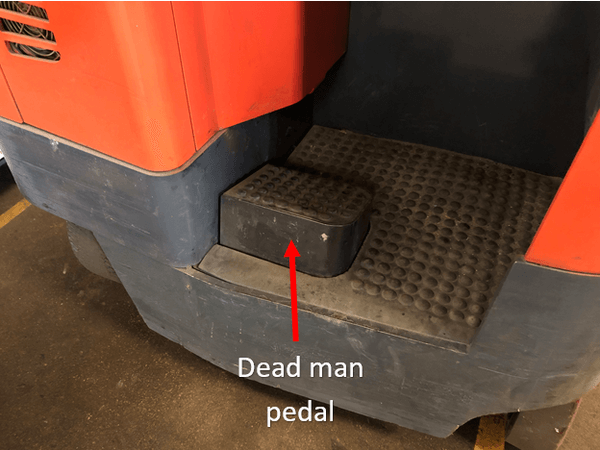

Controls

Most counterbalance forklift controls are quite similar to road vehicles.

That is, they have a steering wheel, gear selector, accelerator pedal, and brake pedal.

Of course, they do have hydraulic controls which road cars don’t.

But beyond that exception, they’re pretty intuitive to operate if you’ve driven a car before.

Reach forklift controls, on the other hand, are quite different from sit-down forklifts.

In a reach truck, the controls include a:

-

Steering wheel

-

Joystick

-

Deadman pedal

Now, the steering wheel is pretty self-explanatory.

But what’s all on the joystick?

This component includes all the functions used to control the truck, such as the:

-

Directional controls for forward and reverse travel

-

Hydraulic controls for mast up/down movement, tilt, extend/retract, and auxiliary functions like sideshift

You may also be unfamiliar with the deadman pedal.

This is a foot pedal that the operator stands on while operating the forklift.

If the operator lifts their foot off the pedal, the truck will automatically shut down.

Why would this be useful?

In a word, “safety.”

The deadman pedal improves safety by preventing the truck from going off on its own in the event the operator isn’t present in the compartment.

Attachments

Reach trucks are mostly limited to using forks on a sideshifter.

But counterbalance forklifts can be equipped with a wide variety of attachments, including:

-

Paper roll clamps

-

Multiple pallet handlers

-

Bale clamps

So, if you need to handle special loads, you’ll need a counterbalance forklift to do so.

Lifting Height

Reach truck masts are designed in much the same way as counterbalance forklift masts are.

(Except for the addition of the pantograph mechanism).

And while similar to other fork truck masts in design, reach truck masts do tend to be taller.

This is because reach trucks are often used in high-racking warehouses.

And the extra height allows warehouses to pack more product vertically rather than horizontally.

How High Can a Reach Truck Reach?

Some models exceed 330 inches of lift height.

Compared to sit-down forklifts, which max out around 240 inches, reach trucks can have an additional 7 feet of lift or even more.

Reach Trucks vs. Other Types of Forklifts

We’ve covered the differences between reach trucks and counterbalance forklifts.

Now, let’s discuss the differences between reach trucks and a few other forklift types that we haven’t talked about.

Reach Trucks vs. Stand-Up Forklifts

First of all, a reach truck is a type of stand-up forklift.

This is based on the simple fact that most reach trucks are operated from a standing position.

But there is such a thing as stand-up counterbalance forklifts.

These are similar to reach trucks in design, except for 2 major differences:

- A stand-up counterbalance forklift mast doesn’t have a pantograph mechanism for “reaching”

- Stand-up counterbalance forklifts do not have base legs – instead, they use a counterweight

Reach Trucks vs. Cherry Pickers

“Cherry pickers” are another name sometimes used for:

- Boom lifts

- Order pickers

Reach trucks and boom lifts are completely different types of equipment.

The former is a forklift, while the latter is a mobile elevating work platform (MEWP).

So what’s the difference between a reach truck and an order picker?

Here’s the answer:

A reach truck’s mast goes up and down to raise and lower a pallet while the operator stays in place in the operator compartment.

But with an order picker, the mast moves the operator themselves up and down (with or without a load).

This is so they can hand-pick materials from pallets in storage.

Reach Trucks vs. Stackers

Stackers are hand-operated forklifts designed to stack pallets on top of one another.

So what’s the difference between a stacker and a reach truck?

One difference is that a stacker’s mast only goes up and down.

Another is that stackers are controlled by an operator standing on the ground and using a tiller arm.

That all said, there is such a thing as a combination stacker and reach truck.

And these are called “walkie reach trucks.”

In this type of forklift, the operator still controls the truck using a tiller arm instead of from within the operator compartment.

But the mast on a walkie reach truck has a pantograph mechanism – just like a reach truck.

Articulated Forklifts vs. Reach Trucks

Articulated forklifts are counterbalanced forklifts.

And both articulated forklifts and reach trucks are designed for narrow aisle applications.

But whereas the reach truck mast extends and retracts, the articulated forklift mast pivots from side to side independent of the body.

This allows an articulated fork truck to retrieve materials from racking without turning the whole body.

On the other hand, a reach truck operator must turn the whole truck chassis to retrieve loads.

Reach Truck Training: Everything You Need to Know

Like all other forklifts, you’ll need to be trained and certified according to OSHA’s standards to operate a reach truck.

And this brings up a common question.

Namely: Can you drive a reach truck with a counterbalance license?

And the answer is no.

Reach truck operators will need additional training specifically on reach trucks if your certification only covers counterbalance forklifts.

OSHA requires this in standard 1910.178(l).

So, what do you need to do to get your reach truck license?

OSHA standards say that you need:

-

Formal instruction

-

Practical training and evaluation

-

Certification

We’ve covered this topic in great detail in our article How to Get Your Forklift License: The Ultimate Guide.

But we’ll briefly cover what reach truck training entails below.

Formal Instruction

OSHA standard 1910.178(l)(2)(ii) requires that operators undergo formal instruction through classroom teaching from a certified instructor.

And standards 1910.178(l)(3)(i) and 1910.178(l)(3)(ii) mandate 22 topics that forklift operators, including reach truck operators, need to undertake to be certified.

These topics cover a wide range of forklift operations, including:

-

How to operate the type of forklift the operator will be using (including instructions, safety precautions, advantages, limitations, etc.)

-

Forklift visibility, capacity, steering, stability, and maneuvering

-

How to stack, unstack, and transport loads

-

How to perform pre-shift inspections

-

Common forklift hazards and precautions

-

Forklift battery charging (electric trucks) and refueling (internal combustion trucks)

Practical Training and Evaluation

During training, operators need to be assessed on the practical operation of the forklift.

What does this mean exactly?

Simply that the trainer must show you both how to operate the forklift and assess your skills and ability when it’s your turn to operate it.

Certification

After training, you will be awarded a certificate showing that you’ve completed the training coursework.

But that’s not enough.

Before you can legally operate a reach truck, your employer (or a qualified 3rd party trainer) must do two things:

- Confirm that you’ve received the required formal and hands-on training

- Evaluate you as you operate a lift truck in your workplace

If your employer or 3rd party trainer is satisfied, then you’re all set to operate a reach truck.

Check out Conger’s OSHA-compliant forklift operator safety training course

How to Operate a Reach Truck

Operating a reach truck is quite different from operating a sit-down counterbalance forklift.

The reason is mostly because, as we’ve mentioned, the controls are so different.

So, let’s give a brief overview of how to operate one.

Reach Truck Operation in 9 Steps

- Enter the operator compartment

- Depress the deadman’s pedal (Always keep pressure on the deadman’s pedal, or the truck will shut down)

- Turn the reach truck on using the ignition

- Lift the forks to the traveling position (4-6 inches off the ground)

- Use the joystick and steering knob to travel forward or backward and change the direction of travel

- Raise the forks to the correct level with the pallet

- Use the joystick to extend the forks forward until they’re underneath the pallet

- Lift the load up just enough so it’s clear from the ground or pallet racking

- Use the joystick to retract the forks and bring the pallet back

You can also watch this video that covers how to operate a reach truck:

Conclusion

That’s it: The differences between reach trucks and forklifts.