Forklift safety is critical for maintaining a secure and productive workplace. With heavy equipment and fast-paced environments, understanding and implementing essential safety tips can prevent accidents and improve efficiency.

Statistics show that forklifts are involved in 11% of workplace injuries which is why understanding safe operations and navigating around forklifts is crucial for reducing workplace accidents.

In this guide, we cover practical forklift safety tips that every operator, manager, and warehouse worker should know to ensure smooth operations and a safe workplace.

Let’s dive in!

Know Your Responsibilities

Maintaining and improving forklift safety is up to the efforts of multiple different parties.

And each has its responsibilities.

Let’s briefly go through them:

Employers, Supervisors, and Managers

These individuals should:

- Create a comprehensive written forklift safety training program.

- Ensure all operators receive proper forklift safety training.

- Place only experienced and competent staff in supervisory roles.

- Monitor employees for compliance with safety rules and protocols.

- Make employees aware of potential hazards.

- Continually identify ways to improve safe operations in the workplace.

- Abide by all government regulations and company policies.

Forklift Operators

What are the duties and responsibilities of a forklift operator?

Here are some of the key ones:

- Comply with all government regulations and company policies.

- Wear proper personal protective equipment (PPE) when working with hazardous substances like fuel and batteries.

- Report any equipment defects to supervisors for correction.

- Work safely and not endanger themselves, coworkers, or the facility.

Conduct Proper Operator Training

Quality forklift training is the single best way to improve forklift safety.

According to OSHA, proper training can prevent an estimated 70% of operator errors.

So what does “proper forklift training” require?

Overall, OSHA forklift requirements state that employers must provide:

- Formal instruction: This includes classroom-based lessons that cover all 22 forklift safety topics listed in standards 1910.178(l)(3)(i) and 1910.178(l)(3)(ii).

- Hands-on training and evaluation: This is where a qualified instructor demonstrates how to operate a forklift and observes students doing so.

- Certification: This is where the operator trainee is observed by a trainer using the forklift in the actual workplace.

However, training doesn’t stop there.

OSHA also mandates that employers provide refresher training at least every three years.

If operators are doing something unsafe or when workplace conditions change, you should provide more frequent refresher training.

Relevant OSHA Standards Expand

- OSHA: “It is a violation of Federal law for anyone UNDER 18 years of age to operate a forklift or for anyone OVER 18 years of age who is not properly trained and certified to do so.”

- 1910.178(l)(1)(i): The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by the successful completion of the training and evaluation specified in this paragraph (l).

- 1910.178(l)(1)(ii): Prior to permitting an employee to operate a powered industrial truck (except for training purposes), the employer shall ensure that each operator has successfully completed the training required by this paragraph (l), except as permitted by paragraph (l)(5).

- 1910.178(l)(2)(ii): Training shall consist of a combination of formal instruction (e.g., lecture, discussion, interactive computer learning, video tape, written material), practical training (demonstrations performed by the trainer and practical exercises performed by the trainee), and evaluation of the operator’s performance in the workplace.

- 1910.178(l)(2)(iii): All operator training and evaluation shall be conducted by persons who have the knowledge, training, and experience to train powered industrial truck operators and evaluate their competence.

- 1910.178(l)(4)(ii): Refresher training in relevant topics shall be provided to the operator when:

- 1910.178(l)(4)(ii)(A): The operator has been observed to operate the vehicle in an unsafe manner;

- 1910.178(l)(4)(ii)(B): The operator has been involved in an accident or near-miss incident;

- 1910.178(l)(4)(ii)(C): The operator has received an evaluation that reveals that the operator is not operating the truck safely;

- 1910.178(l)(4)(ii)(D): The operator is assigned to drive a different type of truck; or

- 1910.178(l)(4)(ii)(E): A condition in the workplace changes in a manner that could affect safe operation of the truck.

- 1910.178(l)(4)(iii): An evaluation of each powered industrial truck operator’s performance shall be conducted at least once every three years.

- 1910.178(l)(6): Certification. The employer shall certify that each operator has been trained and evaluated as required by this paragraph (l). The certification shall include the name of the operator, the date of the training, the date of the evaluation, and the identity of the person(s) performing the training or evaluation.

Install and Maintain Safety Guards

Are you curious about the safety features of forklifts?

The primary safety features include the overhead guard and load backrest.

OSHA mandates that forklifts must have an overhead guard installed, which protects operators from falling objects.

Regular inspections are crucial; check for defects like unauthorized holes and dents.

If any issues exist, take the forklift out of service until repairs or replacements are complete.

To prevent loads from falling backward and causing accidents, OSHA requires the use of load backrests whenever there is a risk involved.

This safety guard helps to keep the load in place. However, operators often remove the load backrest to access higher levels without hitting the ceiling.

Unfortunately, this can increase the chances of items falling off the load. So keep the load backrest installed for added security.

Relevant OSHA Standards Expand

- 1910.178(e)(1): High Lift Rider trucks shall be fitted with an overhead guard manufactured in accordance with paragraph (a)(2) of this section, unless operating conditions do not permit.

- 1910.178(e)(2): If the type of load presents a hazard, the user shall equip fork trucks with a vertical load backrest extension manufactured in accordance with paragraph (a)(2) of this section.

- 1910.178(m)(9): An overhead guard shall be used as protection against falling objects. It should be noted that an overhead guard is intended to offer protection from the impact of small packages, boxes, bagged material, etc., representative of the job application, but not to withstand the impact of a falling capacity load.

- 1910.178(m)(10): A load backrest extension shall be used whenever necessary to minimize the possibility of the load or part of it from falling rearward.

Do Not Modify Your Forklift

If you are considering making modifications to your forklift yourself – STOP!

Unauthorized modifications violate OSHA’s rules, which state:

Modifications and additions that affect capacity and safe operation shall not be performed by the customer or user without the manufacturer’s prior written approval. Capacity, operation, and maintenance instruction plates, tags, or decals shall be changed accordingly.

OSHA Standard 1910.178(a)(4)

One particularly concerning modification we sometimes see is drilling holes in the overhead guard.

These holes are typically drilled into the overhead guard to mount accessories like mirrors, lights or other safety products.

However, even small drill holes can affect the integrity of the overhead guard, making them a significant safety concern.

Use Proper Lighting to Improve Warehouse Safety

Commonly, forklifts operate in low-light areas such as warehouses, semi-trailers, and rail cars.

If these environments lack proper lighting, operators are more likely to collide with pedestrians or products.

That is why it is crucial to have forklift safety lights to minimize this. However, how much light is too little light?

OSHA says the limit is anything less than 2 lumens per square foot. If you are unsure how much light that is, an average bedroom ranges between 10 to 20 lumens per square foot.

Relevant OSHA Standards Expand

- 1910.178(h)(2): Where general lighting is less than 2 lumens per square foot, auxiliary directional lighting shall be provided on the truck.

Install Gas Detectors

Liquefied petroleum gas (LPG) powered forklifts are generally preferred indoors over gasoline or diesel engines because they emit fewer dangerous gases like carbon monoxide (CO).

However, despite their low gas emissions, you should still monitor the concentration of these gases in your work environment.

Failure to monitor gas levels could lead to dangerous levels of CO in the work environment, which could result in workers becoming seriously ill or even dying due to carbon monoxide poisoning.

So, what exactly is the CO limit, and how do we keep below it?

According to OSHA, CO must not exceed 50 parts per million (ppm) at 77° F and 760 torr.

That equates to approximately 55 milligrams per cubic meter of air.

Relevant OSHA Standards Expand

- 1910.178(i)(1): Concentration levels of carbon monoxide gas created by powered industrial truck operations shall not exceed the levels specified in §1910.1000.

Use Care When Loading and Unloading Trailers

Many forklift operators have to load and unload semi-trailers at the dock as part of their job.

However, this routine activity carries plenty of risks and requires strict procedures to safeguard from injury.

Use extra caution when loading and unloading semi-trailers

What are those procedures?

- Ensure the semi-truck brakes are engaged and that the wheels are chocked.

- Use fixed jacks to support a semi-trailer when not coupled to the tractor.

- Properly secure dock plates.

- Ensure the forklift and load do not exceed the dock plate’s rated capacity.

Operators that follow these procedures can help avoid dangerous situations like run-away trailers and falls from the dock.

Relevant OSHA Standards Expand

- 1910.178(k)(1): The brakes of highway trucks shall be set and wheel chocks placed under the rear wheels to prevent the trucks from rolling while they are boarded with powered industrial trucks.

- 1910.178(k)(2): Wheel stops or other recognized positive protection shall be provided to prevent railroad cars from moving during loading or unloading operations.

- 1910.178(k)(3): Fixed jacks may be necessary to support a semitrailer and prevent upending during the loading or unloading when the trailer is not coupled to a tractor.

- 1910.178(n)(11): Dockboard or bridgeplates, shall be properly secured before they are driven over. Dockboard or bridgeplates shall be driven over carefully and slowly and their rated capacity never exceeded.

Inspect Before Operating

OSHA requires that all forklifts be inspected prior to operation.

Why?

To determine the safety of the forklift.

Usually, these are performed by the operator and are known as preoperational inspections.

Using a checklist, the operator should walk around the forklift and examine the critical areas for any signs of wear, damage, or deficiency.

Download Our Free Forklift Safety Checklists

Any part in poor condition should be reported and corrected before operating.

Relevant OSHA Standards Expand

- 1910.178(q)(7): Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily. Where industrial trucks are used on a round-the-clock basis, they shall be examined after each shift. Defects when found shall be immediately reported and corrected.

Keep Up on Maintenance

Forklift maintenance helps ensure your forklifts last as long as possible.

However, it is also a significant component of forklift safety procedures.

After all, a defective forklift component – like brakes – can result in injury, fatality, and damage to the product.

So, keeping up with regular maintenance activities is a must.

If you have an in-house maintenance team, ensure they follow up on any issues noted by your operators.

If you don’t have an in-house maintenance team, consider outsourcing your forklift maintenance to a reliable service center. If you are in Green Bay, Wausau, Neenah, or anywhere else in Wisconsin, check out Conger. They are more than just your local Toyota dealer; their expert team specializes in material handling and is ready to help keep your machines operational.

Relevant OSHA Standards Expand

- 1910.178(q)(7): Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily. Where industrial trucks are used on a round-the-clock basis, they shall be examined after each shift. Defects when found shall be immediately reported and corrected.

- 1910.178(p)(1): If at any time a powered industrial truck is found to be in need of repair, defective, or in any way unsafe, the truck shall be taken out of service until it has been restored to safe operating condition.

- 1910.178(q)(1): Any power-operated industrial truck not in safe operating condition shall be removed from service. All repairs shall be made by authorized personnel.

How to Safely Dismount a Tipping Forklift

The number 1 cause of forklift deaths is tip-overs. This fact makes it crucial to know how to handle this situation.

Knowing what to do during a tip-over can be tricky because the guidelines for these incidents differ depending on the forklift type.

If you’re operating a sit-down style forklift here are the forklift safety tips you should follow:

- Stay in your seat

- Brace yourself

- Lean away from the point of impact

Here are the stand-up forklift safety tips if you’re operating a stand-up rider forklift that starts to tip:

- Step back from the operator compartment

- Move as far away from the forklift as possible

Relevant OSHA Standards Expand

- 1910.178(q)(7): Industrial trucks shall be examined before being placed in service, and shall not be placed in service if the examination shows any condition adversely affecting the safety of the vehicle. Such examination shall be made at least daily. Where industrial trucks are used on a round-the-clock basis, they shall be examined after each shift. Defects when found shall be immediately reported and corrected.

- 1910.178(p)(1): If at any time a powered industrial truck is found to be in need of repair, defective, or in any way unsafe, the truck shall be taken out of service until it has been restored to safe operating condition.

- 1910.178(q)(1): Any power-operated industrial truck not in safe operating condition shall be removed from service. All repairs shall be made by authorized personnel.

Install an Operator Restraint System

What is the most important safety device on a forklift?

Answer: The seat belt.

Why?

Seat belts are the best way to prevent operators from being crushed during a tip-over.

Sit-down rider forklifts manufactured after 1992 the seats to have seat belts installed from the factory.

However, if your forklifts are older than 1992 models, you should still arrange to have seat belts installed on them.

Furthermore, managers should ensure forklift maintenance includes replacing worn or damaged seat belts.

Don’t Speed

Speed kills!

Considering that the average warehouse forklift weighs around 9,000 lbs., this adage is especially true.

Because with that much weight, forklifts take longer to stop.

How long does it take to stop a forklift at full speed?

According to National Safety, Inc. it’s as follows:

- At four mph, it will take 17 feet to come to a stop.

- At eight mph, it will take 42 feet.

- At nine mph, it will take at least 51 feet.

Now, you might wonder: What is the maximum safe speed for a forklift?

The University of Rochester recommends:

- Eight mph when no pedestrians are present.

- Three mph when pedestrians are present.

However, keeping operators under the speed limit can be a challenge.

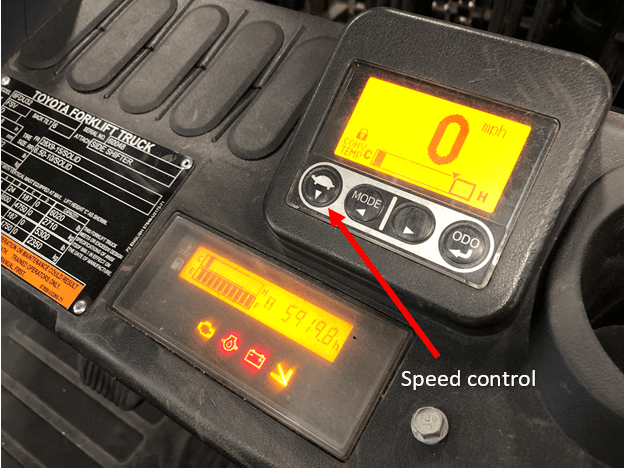

Fortunately, facility managers who struggle with this have an effective option: Electronic speed control.

Many modern forklifts have this feature standard from the factory.

All it takes is having the dealership set the speed and a password to prevent unauthorized changes.

Relevant OSHA Standards Expand

- 1910.178(n)(1): All traffic regulations shall be observed, including authorized plant speed limits. A safe distance shall be maintained approximately three truck lengths from the truck ahead, and the truck shall be kept under control at all times.

- 1910.178(n)(8): Under all travel conditions the truck shall be operated at a speed that will permit it to be brought to a stop in a safe manner.

- 1910.178(n)(10): The driver shall be required to slow down for wet and slippery floors.

- 1910.178(n)(15): While negotiating turns, speed shall be reduced to a safe level by means of turning the hand steering wheel in a smooth, sweeping motion. Except when maneuvering at a very low speed, the hand steering wheel shall be turned at a moderate, even rate.

Handle Loads Properly

Forklifts’ primary function is to pick stuff up and put it down, but proper load handling is not quite that simple.

That’s because loads come in all different shapes, sizes, and weights.

The key to proper load handling is ensuring your loads are stable and balanced.

To do so, operators should make sure they:

- Use extra caution when handling off-center loads.

- Secure loose items on loads to prevent them from falling.

- Put the forks as far as possible under the load.

- Refrain from tilting unless directly above the deposit position.

Following these load-handling safety tips will help minimize falling loads and forklift instability.

Relevant OSHA Standards Expand

- 1910.178(o)(1): Only stable or safely arranged loads shall be handled. Caution shall be exercised when handling off-center loads which cannot be centered.

- 1910.178(o)(5): A load engaging means shall be placed under the load as far as possible; the mast shall be carefully tilted backward to stabilize the load.

- Note: “Load engaging means” refers to the forks or attachment

- 1910.178(o)(6): Extreme care shall be used when tilting the load forward or backward, particularly when high tiering. Tilting forward with load engaging means elevated shall be prohibited except to pick up a load. An elevated load shall not be tilted forward except when the load is in a deposit position over a rack or stack. When stacking or tiering, only enough backward tilt to stabilize the load shall be used.

Keep a Clear Line of Sight

Forklift operators routinely deal with oversized loads that obscure their vision.

However, it’s crucial to maintain maximum visibility at all times to prevent forklift accidents.

Thus, operators should take precautions when their sight is blocked.

This includes:

- Travel backward when the load blocks their view.

- Slow down and honking the horn at intersections.

- Use a forklift spotter to navigate blind spots.

Facility managers can help by installing mirrors on forklift and at intersections.

A common question is: Does OSHA require forklift mirrors?

According to EHS Daily Advisor, OSHA doesn’t specifically require them.

But if they’re factory-installed, do not remove them.

Relevant OSHA Standards Expand

- 1910.178(n)(4): The driver shall be required to slow down and sound the horn at cross aisles and other locations where vision is obstructed. If the load being carried obstructs forward view, the driver shall be required to travel with the load trailing.

- 1910.178(n)(6): The driver shall be required to look in the direction of, and keep a clear view of the path of travel.

Look Out for Pedestrians

Forklift operators look out for many things while operating their vehicles, but pedestrians are the biggest concern.

In 2017, the U.S. Bureau of Labor Statistics found that pedestrian collisions resulted in 13% of forklift fatalities.

Operators can improve how they interact with pedestrians in the following ways:

- Sound the horn around corners or any areas where you don’t have a clear view.

- Make eye contact with pedestrians to alert them to your presence.

- Grant pedestrians the right-of-way whenever you encounter them.

- Use verbal or hand signals to let pedestrians know your next move.

- Never drive up to a person in front of a fixed object.

Pedestrian safety isn’t all on the operators, however.

By doing the following, pedestrians can help minimize their risk of collision with forklifts:

- Walk on the right side of the aisles.

- Keep your distance from operating forklifts.

- Watch out for tail swing to help avoid pinning.

Keeping these forklift safety tips for pedestrians in mind can greatly improve workplace safety.

Relevant OSHA Standards Expand

- 1910.178(m)(1): Trucks shall not be driven up to anyone standing in front of a bench or other fixed object.

Separate Foot and Forklift Traffic

Separating the different types of traffic in your facility can go a long way toward improving pedestrian safety.

We’ve covered many pedestrian safety tips in the previous section.

- Keep proper aisle widths to allow safe distances between equipment and workers on foot.

- Mark pedestrian and forklift traffic in aisles.

- Keep some aisles designated for pedestrian- or forklift-only traffic.

- Limit forklift use near break rooms, restrooms, time clocks, exits, and other places where pedestrians congregate.

- Install physical barriers and pedestrian safety gates around workstations and walkways.

- Install forklift traffic signs to alert foot traffic to the presence of equipment.

Do Not Allow Passengers

Can you carry passengers in your forklift?

The answer is no – unless there’s a designated seat for them.

Without a safe spot for passengers, they are at greater risk of harm if the forklift tips over.

Relevant OSHA Standards Expand

- 1910.178(m)(3): Unauthorized personnel shall not be permitted to ride on powered industrial trucks. A safe place to ride shall be provided where riding of trucks is authorized.

Use the Right Equipment to Elevate Workers

Falls from forklifts caused 15% of forklift fatalities in 2017.

How does this happen?

Falls usually occur when the forklift operator allows a coworker to stand on the forks while they lift them to the worksite.

This is extremely dangerous because even a fall from as little as 7 feet can cause death.

So, what’s the solution?

Only lift personnel with equipment designed exclusively for that purpose.

That means using mobile elevated work platforms (MEWPs), like scissor lifts and boom lifts.

If you don’t have this equipment available, there’s another option: Lifting cages.

Personnel can enter the cage, secure themselves, and be lifted to their work height.

Just make sure that you follow a few rules when working with forklift safety cages:

- Use only approved lifting cages

- Secure the cage to the carriage or forks

- Use restraining devices like body harnesses to secure workers to the cage

- Never drive with the cage elevated

Ascend and Descend Ramps Properly

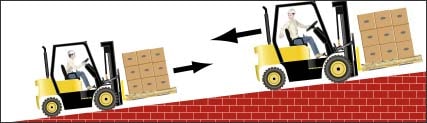

Navigating ramps is one of the most dangerous activities for forklift operators.

The reason is that even slight grades can cause the forklift to become unstable.

And this is magnified if the operator turns while on the ramp.

Because doing so can easily cause the forklift to tip over.

To minimize the chances of this happening, operators should:

- Drive slowly up and down ramps.

- Drive with the load upgrade to minimize the chances of it falling off the forks.

- Never turn on a ramp if at all possible.

Relevant OSHA Standards Expand

- 1910.178(n)(7): Grades shall be ascended or descended slowly.

- 1910.178(n)(7)(i): When ascending or descending grades in excess of 10 percent, loaded trucks shall be driven with the load upgrade.

- 1910.178(n)(7)(iii): On all grades the load and load engaging means shall be tilted back if applicable, and raised only as far as necessary to clear the road surface.

Secure Unattended Forklifts

It’s not uncommon for some forklift operators to spend their entire shift on their forklift.

But more often than not, operators are on and off their forklift throughout their day.

If that’s the case, it’s necessary to take proper precautions when leaving a forklift unattended.

Now, you might be wondering: At what distance is a forklift considered to be unattended?

Fortunately, OSHA provides an answer to this question:

“A powered industrial truck is unattended when the operator is 25 ft. or more away from the vehicle which remains in his view, or whenever the operator leaves the vehicle and it is not in his view.”

OSHA Standard 1910.178(m)(5)(ii)

In that case, the operator has a responsibility to secure their forklift by:

- Lower the forks.

- Turn off the power.

- Set the parking brake.

Another popular question people ask is: Can you leave keys in a forklift?

We could not find where OSHA addresses this specifically, but the answer should be “No.“

Why should you remove the key from your forklift?

It is the best practice to prevent unauthorized people from powering up the forklift.

Relevant OSHA Standards Expand

- 1910.178(m)(5)(i): When a powered industrial truck is left unattended, load engaging means shall be fully lowered, controls shall be neutralized, power shall be shut off, and brakes set. Wheels shall be blocked if the truck is parked on an incline.

- 1910.178(m)(5)(ii): A powered industrial truck is unattended when the operator is 25 ft. or more away from the vehicle which remains in his view, or whenever the operator leaves the vehicle and it is not in his view.

- 1910.178(m)(5)(iii): When the operator of an industrial truck is dismounted and within 25 ft. of the truck still in his view, the load engaging means shall be fully lowered, controls neutralized, and the brakes set to prevent movement.

Keep Your Equipment Clean

Regularly clean your forklift to ensure it operates efficiently since many forklifts operate in dirty environments.

In many operating environments, debris and dirt accumulation can interfere with the vehicle’s mechanical components and limit performance.

But another reason to keep your forklifts clean is for safety purposes.

If the forklift has grease and grim on the steering wheel, pedals, or control levers, the operator’s grip won’t be as secure.

Without a secure hold, the operator won’t have total control over their forklift which can result in serious accidents.

Relevant OSHA Standards Expand

- 1910.178(q)(10): Industrial trucks shall be kept in a clean condition, free of lint, excess oil, and grease. Noncombustible agents should be used for cleaning trucks. Low flash point (below 100 °F.) solvents shall not be used. High flash point (at or above 100 °F.) solvents may be used. Precautions regarding toxicity, ventilation, and fire hazard shall be consonant with the agent or solvent used.

Follow Safe Refueling Procedures

Most forklifts run on either LPG, gasoline, diesel, or electricity.

Each of these fuel sources poses its unique risks when it comes time to refuel.

So, operators should be aware of the safety practices when refueling and ensure they follow them closely.

Some forklift propane safety tips include:

- Turning off the engine on internal combustion (IC) forklifts before refueling.

- Eliminate ignition sources (like smoking) when near fuel sources.

- Follow safe lifting procedures when removing a full LPG tank that can weigh over 84 lbs.

- Wear proper personal protective equipment like a face mask and gloves when handling propane.

Some forklift battery safety tips include:

- Charging batteries for electric forklifts only in designated areas.

- Using proper material handling equipment for removing batteries.

- Not smoking in the charging areas.

- Opening the hood when charging to ventilate and dissipate heat.

Relevant OSHA Standards Expand

- 1910.178(m)(2): No person shall be allowed to stand or pass under the elevated portion of any forklift, whether loaded or empty.

Never Walk Under Elevated Forks

This tip is for pedestrians to stay safe in the work environment.

Now, why is it important not to walk under the forks of a lift truck?

- The operator may not see and inadvertently lower the load on the pedestrian.

- An unstable load may fall off the forks and onto the pedestrian.

- The lifting mechanism can malfunction and come down on the pedestrian.

Whichever scenario it is, it’s not a result that anyone wants.

So, if you see an elevated forklift mast, maintain plenty of space and walk around it.

Relevant OSHA Standards Expand

- 1910.178(g)(1): Battery charging installations shall be located in areas designated for that purpose.

- 1910.178(g)(2): Facilities shall be provided for flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation for dispersal of fumes from gassing batteries.

- 1910.178(g)(4): A conveyor, overhead hoist, or equivalent material handling equipment shall be provided for handling batteries.

- 1910.178(g)(5): Reinstalled batteries shall be properly positioned and secured in the truck.

- 1910.178(g)(8): Trucks shall be properly positioned and brake applied before attempting to change or charge batteries.

- 1910.178(g)(10): Smoking shall be prohibited in the charging area.

- 1910.178(g)(11): Precautions shall be taken to prevent open flames, sparks, or electric arcs in battery charging areas.

- 1910.178(g)(12): Tools and other metallic objects shall be kept away from the top of uncovered batteries.

- 1910.178(p)(2): Fuel tanks shall not be filled while the engine is running. Spillage shall be avoided.

Keep Your Work Environment Clean, Clear, and In Good Repair

Without a clean and safe work environment, the chances of a forklift accident go up.

To reduce this, employers should:

- Conduct regular walk-throughs to identify obstructions and clutter that pose a risk and make plans to correct them.

- Keep stairways and escape routes free of obstructions.

- Inspect and repair any cracks or damage to loading docks and pallet racking.

Forklift operators can help by first walking routes and clearing obstructions before proceeding.

Relevant OSHA Standards Expand

- 1910.141(a)(3)(i): All places of employment shall be kept clean to the extent that the nature of the work allows.

Do Not Run Over Debris

If you follow the previous safety tip, you can eliminate this hazard.

Still, especially tough work environments will never be free of debris.

In that case, forklift operators should do everything to avoid running it over.

Why?

Debris can chunk out tires, cause damage to critical forklift components, and introduce instability.

When that happens, the risk of a forklift accident increases, and the cost of maintenance and repairs.

Relevant OSHA Standards Expand

- 1910.178(n)(14): Running over loose objects on the roadway surface shall be avoided.

Be Mindful of the Hazards of Your Forklift

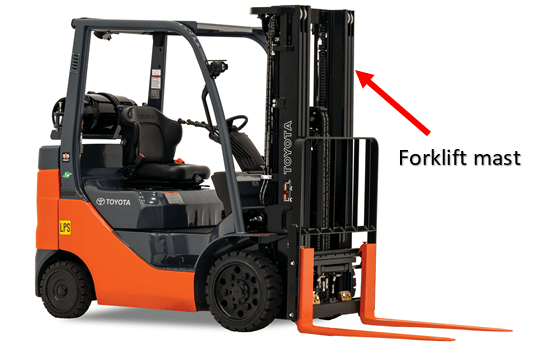

One of the most dangerous components of a forklift is the mast.

If you’re unfamiliar, this mechanism allows the forks and load to travel up and down.

Due to its design, the mast can cause serious injury to anyone who places a body part within it.

So, always keep fingers, hands, and limbs away from the chains, the rails, and the pulleys.

Additionally, operators should never extend their arms or legs outside the operator compartment while riding.

This rule also includes placing your hand on the rear overhead guard post while backing up.

If an operator does so, they can easily crush their hands against a fixed object like a wall.

And that can cause serious injury.

Relevant OSHA Standards Expand

- 1910.178(m)(4): The employer shall prohibit arms or legs from being placed between the uprights of the mast or outside the running lines of the truck.

Never Exceed the Rated Capacity

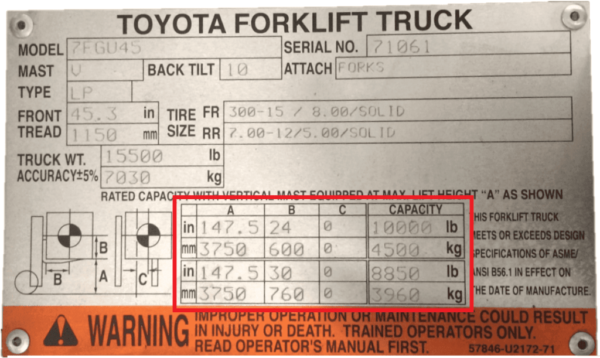

Forklifts are usually referred to by their nominal capacity.

For instance, a 5,000-pound forklift can lift 5,000 pounds to a certain height.

However, this can be misleading because attachments like side shifters can reduce the actual lifting capacity.

Therefore, it’s crucial to understand your true weight-lifting ability.

How can you determine this?

Check your forklift’s data plate, which lists any attachments and shows the weight the forklift can lift at specified heights.

Once you have this information, never lift anything that exceeds the limit.

Overloading can lead to problems such as tip-overs, falling loads, and loss of control.

Relevant OSHA Standards Expand

- 1910.178(o)(2): Only loads within the rated capacity of the truck shall be handled.

- 1910.178(a)(6): The user shall see that all nameplates and markings are in place and are maintained in a legible condition.

Don’t Talk and Operate

Distracted driving isn’t just a problem on the open road.

It is also a significant issue for facilities that operate forklifts.

Among the main problems is the use of cell phones.

Operators should never talk or text while operating their forklift.

Pedestrians should take extra care when using their phones while in proximity to forklifts.

Relevant OSHA Standards Expand

- OSHA’s General Duty Clause:

- (a) Each employer — shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees

Conclusion

Prioritizing forklift safety is an investment in your team’s well-being and your operation’s success. By following these safety tips, you can reduce risks, improve productivity, and create a safer workplace for everyone. Remember, safety is a shared responsibility—commit to continuous training, regular maintenance, and open communication to keep your workplace accident-free.